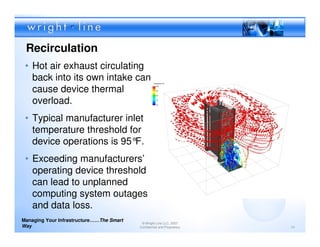

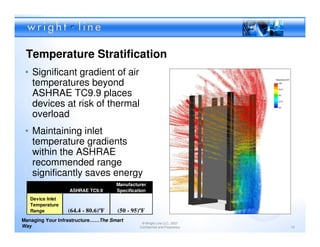

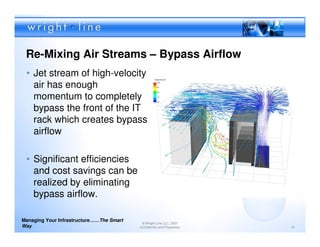

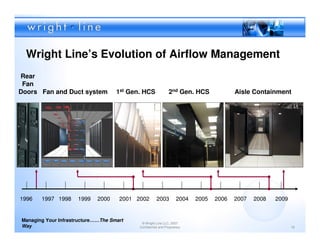

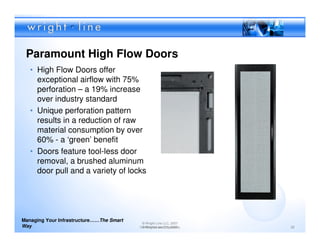

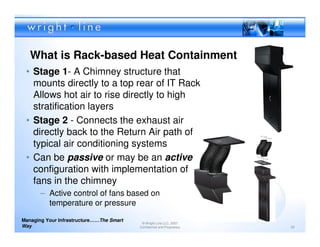

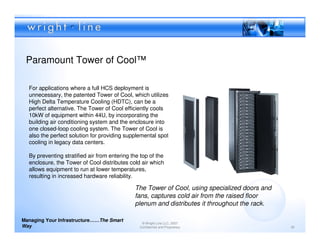

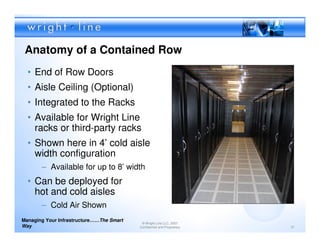

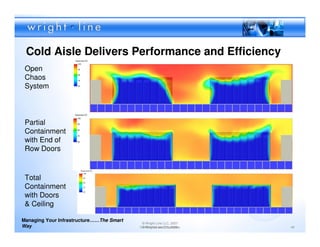

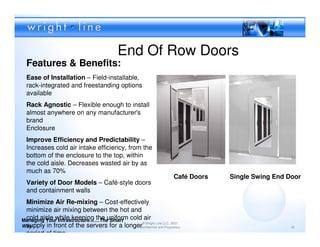

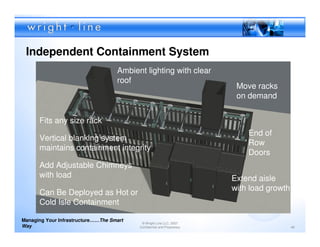

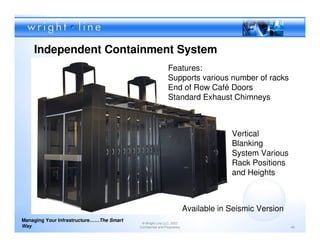

The document discusses data center air flow solutions and the challenges associated with power consumption and energy efficiency in IT infrastructure. It emphasizes the importance of optimizing air flow management to reduce operational costs and improve cooling efficiency, particularly in legacy data centers. Wright Line offers various strategies, including cold aisle containment, hot aisle containment, and rack-based heat containment, to address issues of heat and power management in data centers.