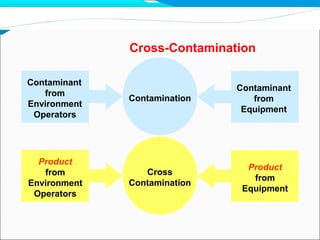

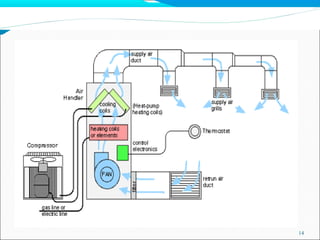

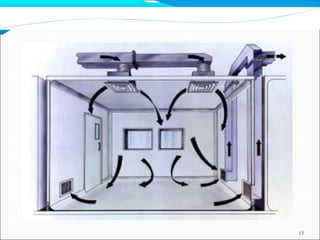

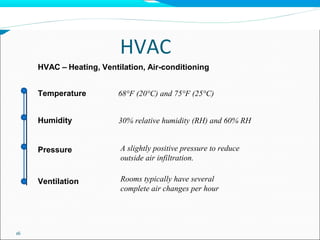

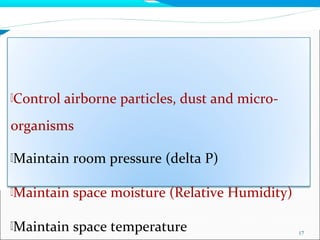

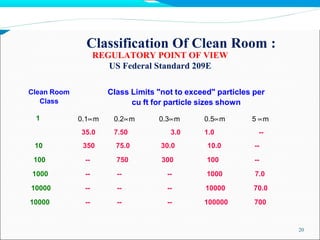

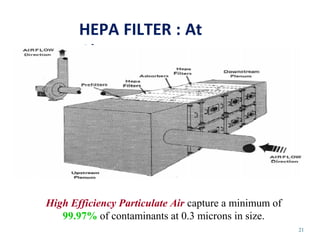

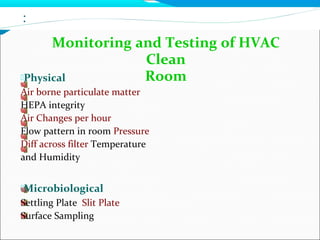

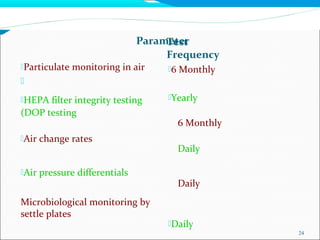

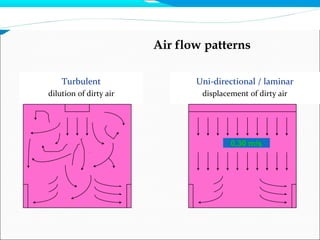

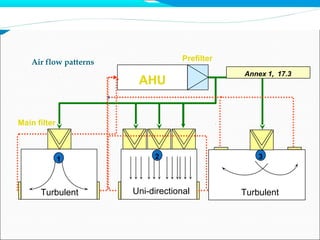

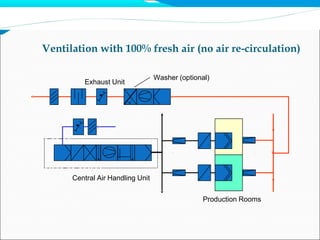

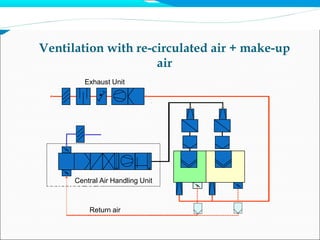

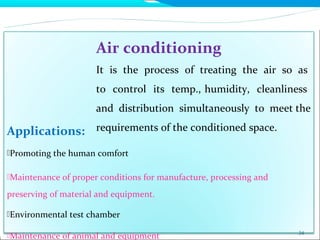

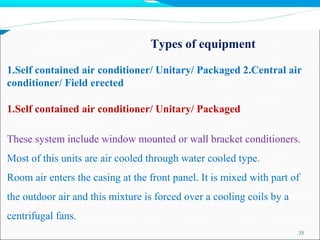

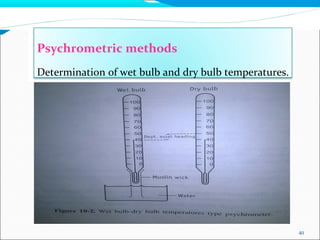

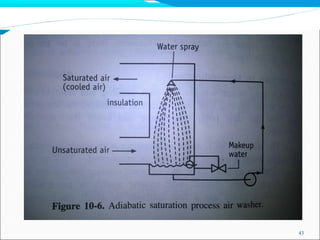

This document discusses heating, ventilation, and air conditioning (HVAC) systems and their importance in manufacturing quality pharmaceutical products. It addresses how HVAC systems control factors like temperature, humidity, air particles, and microbes. Contamination can originate from the environment, operators, or equipment and cross-contamination needs to be minimized. Proper HVAC design, maintenance, and procedures are critical to maintaining clean manufacturing conditions. The document also defines humidity measurement and different HVAC system types like central air conditioning. Dehumidification is important for operations in humid climates. In conclusion, air handling systems are critical systems that must be properly designed and treated as such.