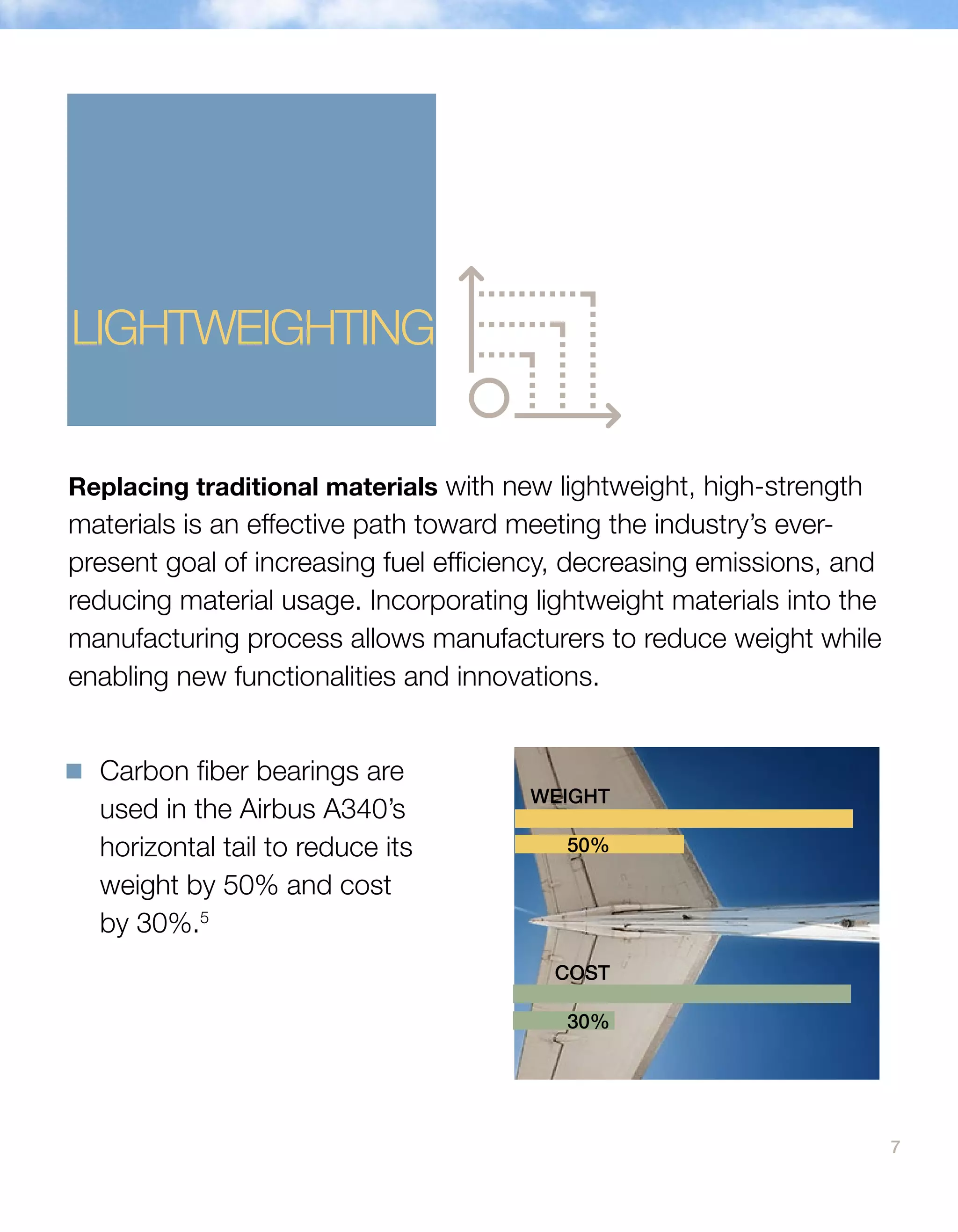

The aerospace industry is poised for growth due to increasing passenger traffic, higher production rates, and technological advancements, with an estimated 1,420 large commercial aircraft to be produced in 2016, reflecting a 40.5% increase over five years. Key trends include automation, lightweighting, new materials, and additive manufacturing, all aimed at improving efficiency and reducing costs in manufacturing processes. The document also highlights the importance of addressing skilled labor shortages and presents new technologies like laser coating removal and high-power ultrasonics that enhance production capabilities.