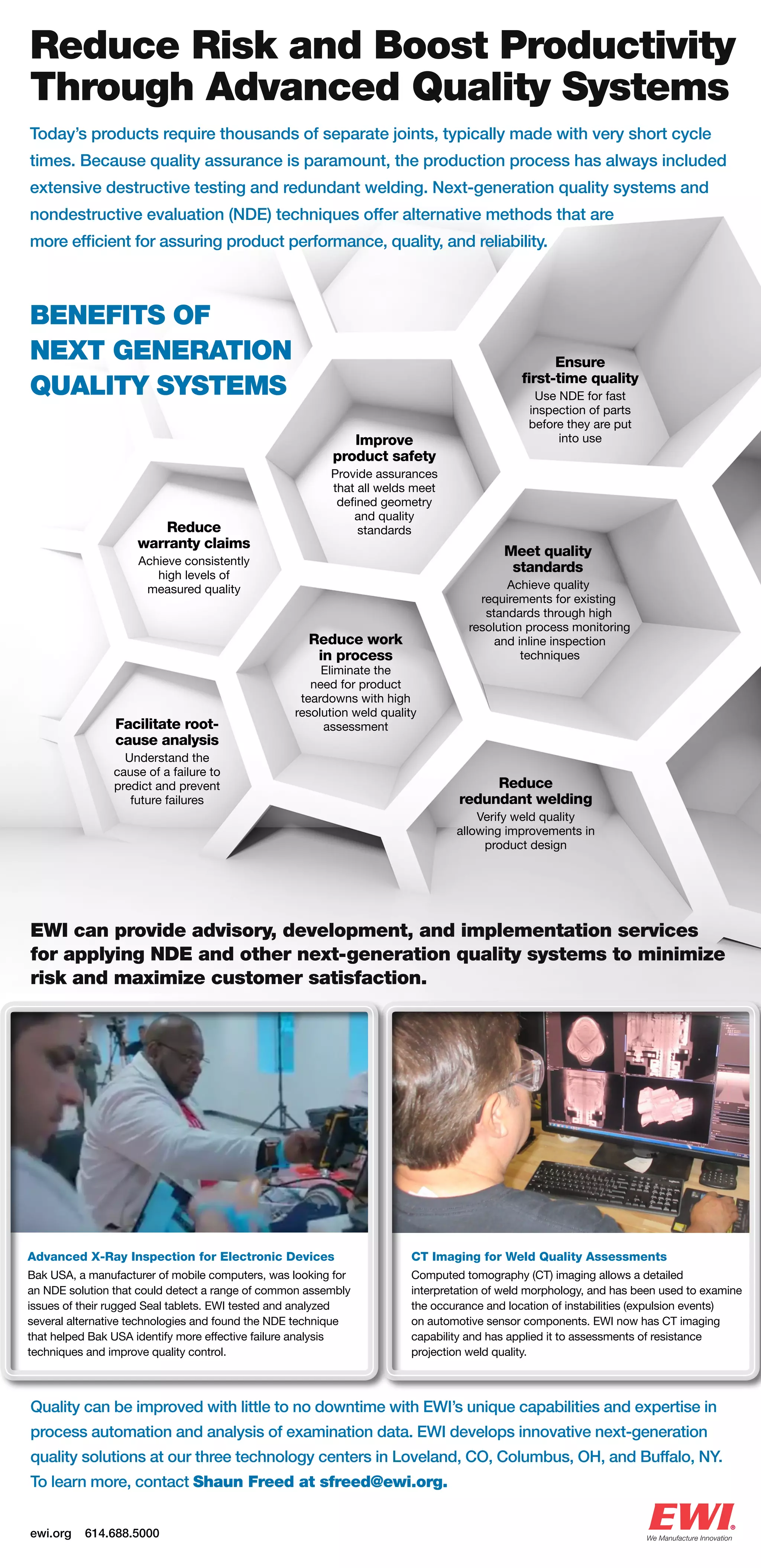

EWI specializes in improving quality through process automation and inspection techniques, utilizing three technology centers in the U.S. Their next-generation quality systems and nondestructive evaluation (NDE) methods reduce risks and enhance productivity, offering efficient alternatives to traditional testing. EWI's innovations include CT imaging for weld assessments and advanced x-ray inspection for electronic devices, providing manufacturers with improved quality control solutions.