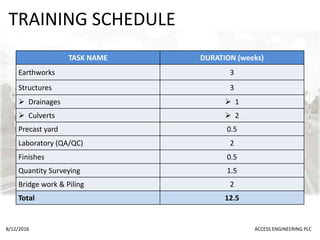

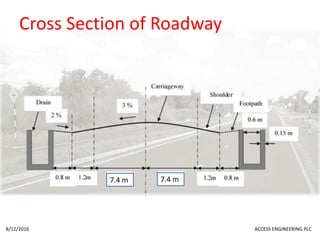

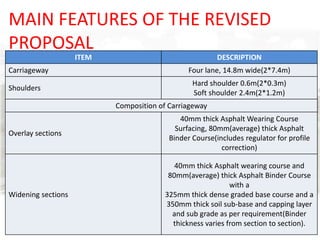

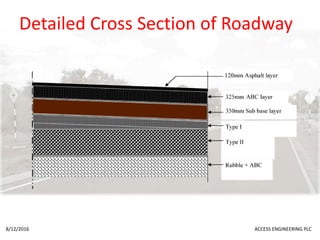

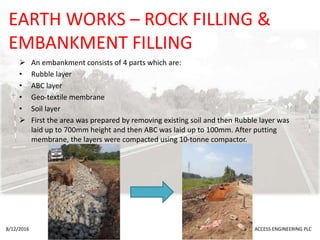

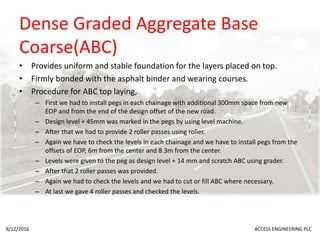

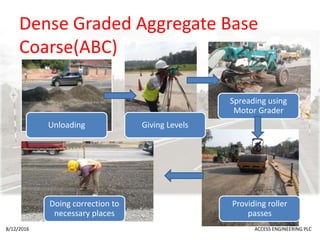

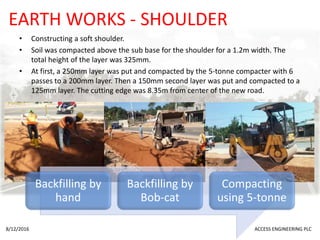

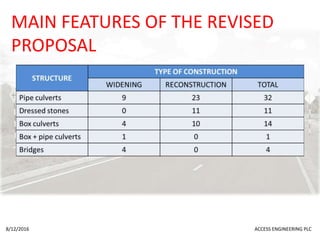

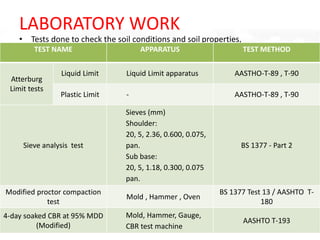

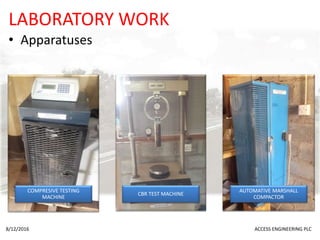

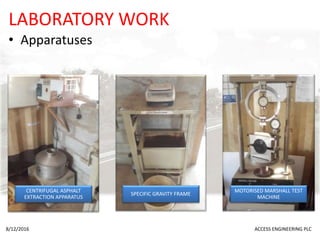

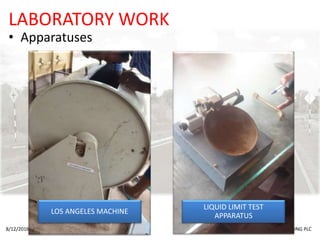

The document provides details about a rehabilitation project of the Colombo-Kandy road section from Kadawatha to Nittambuwa being carried out by Access Engineering PLC. The 23km project includes improvements to the road, pavements, and bridges over an 18 month period. Earthworks include embankment filling, sub-base construction and culvert/drainage installation. Laboratory testing is being conducted to ensure quality control. Safety and environmental policies are also in place for the project.