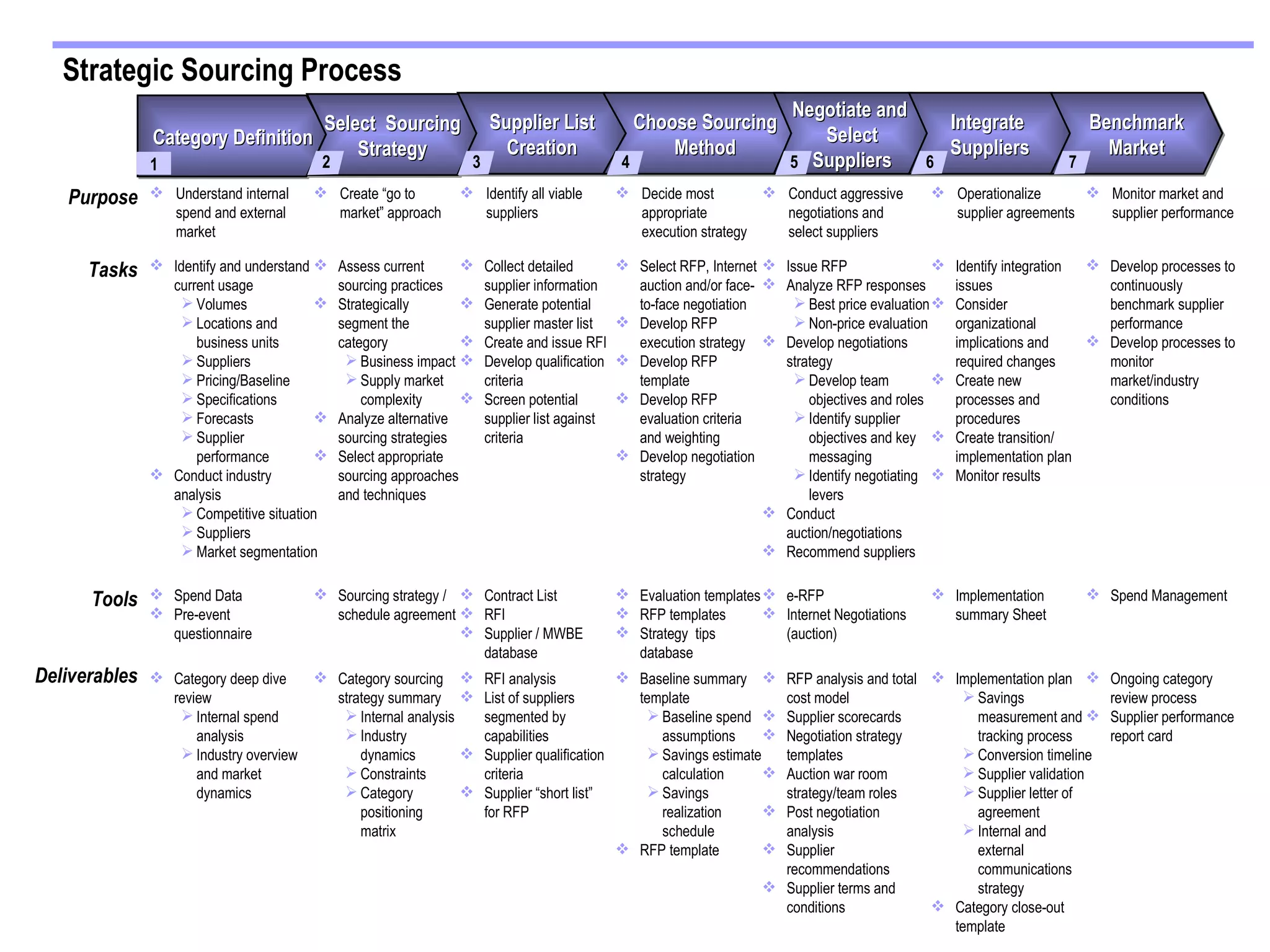

The strategic sourcing process involves identifying a company's current category usage, conducting a supplier and market analysis, selecting an appropriate sourcing strategy, and choosing a sourcing method. Key steps include developing requests for information and proposals, evaluating responses, negotiating with suppliers, integrating new suppliers, and monitoring market performance and supplier relationships on an ongoing basis. The process aims to identify all viable suppliers, execute the best sourcing approach, conduct negotiations to select suppliers, and operationalize agreements while monitoring the category.