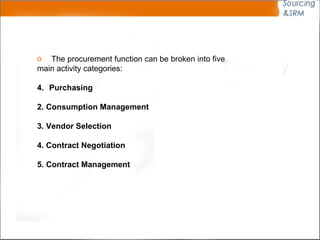

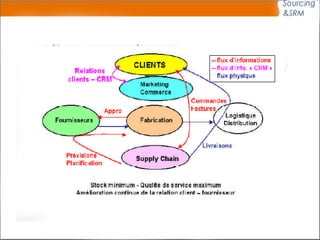

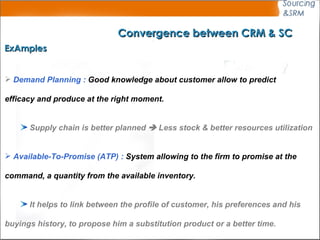

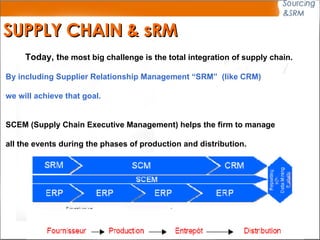

The document outlines the essential aspects of sourcing and procurement functions, highlighting key activities such as supplier selection, vendor management, contract negotiation, and contract management. It emphasizes the importance of both direct and indirect purchasing, efficient communication, and decision support tools for bid evaluation. Additionally, it discusses the integration of supply chain management and customer relationship management to enhance operational efficiency and improve service quality.