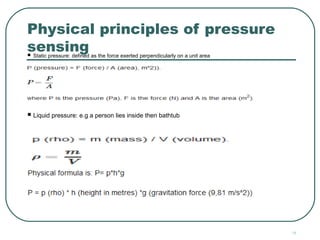

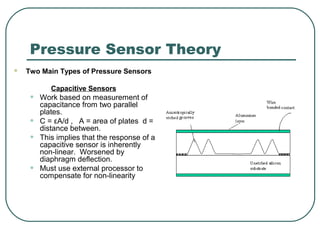

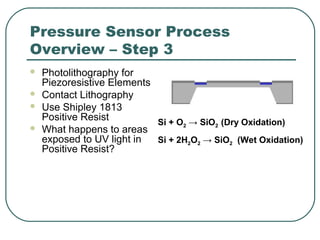

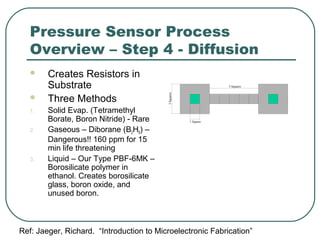

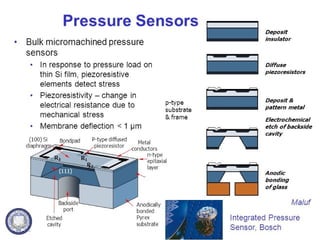

The document describes the fabrication process for a piezoresistive pressure sensor using a surface micromachined silicon wafer. The key steps include (1) thermal oxidation to grow a silicon dioxide layer, (2) boron diffusion through photolithography to form piezoresistors in the substrate, and (3) a backside etch to create a thin diaphragm over which pressure can be measured through deflection. The process uses common microfabrication techniques such as cleaning, deposition, lithography, diffusion, and etching to create a functional pressure sensor on a silicon chip for pressure sensing applications.