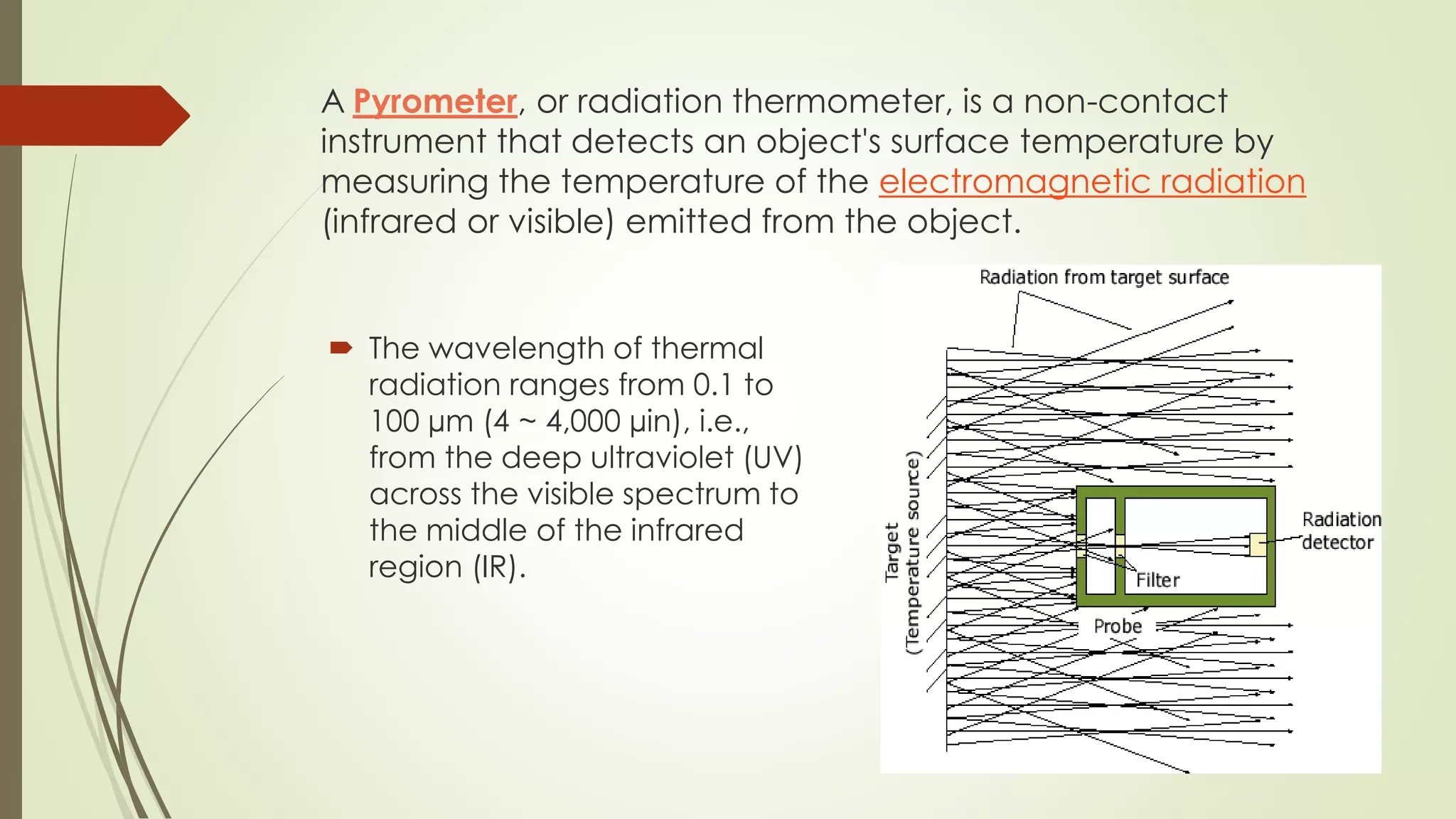

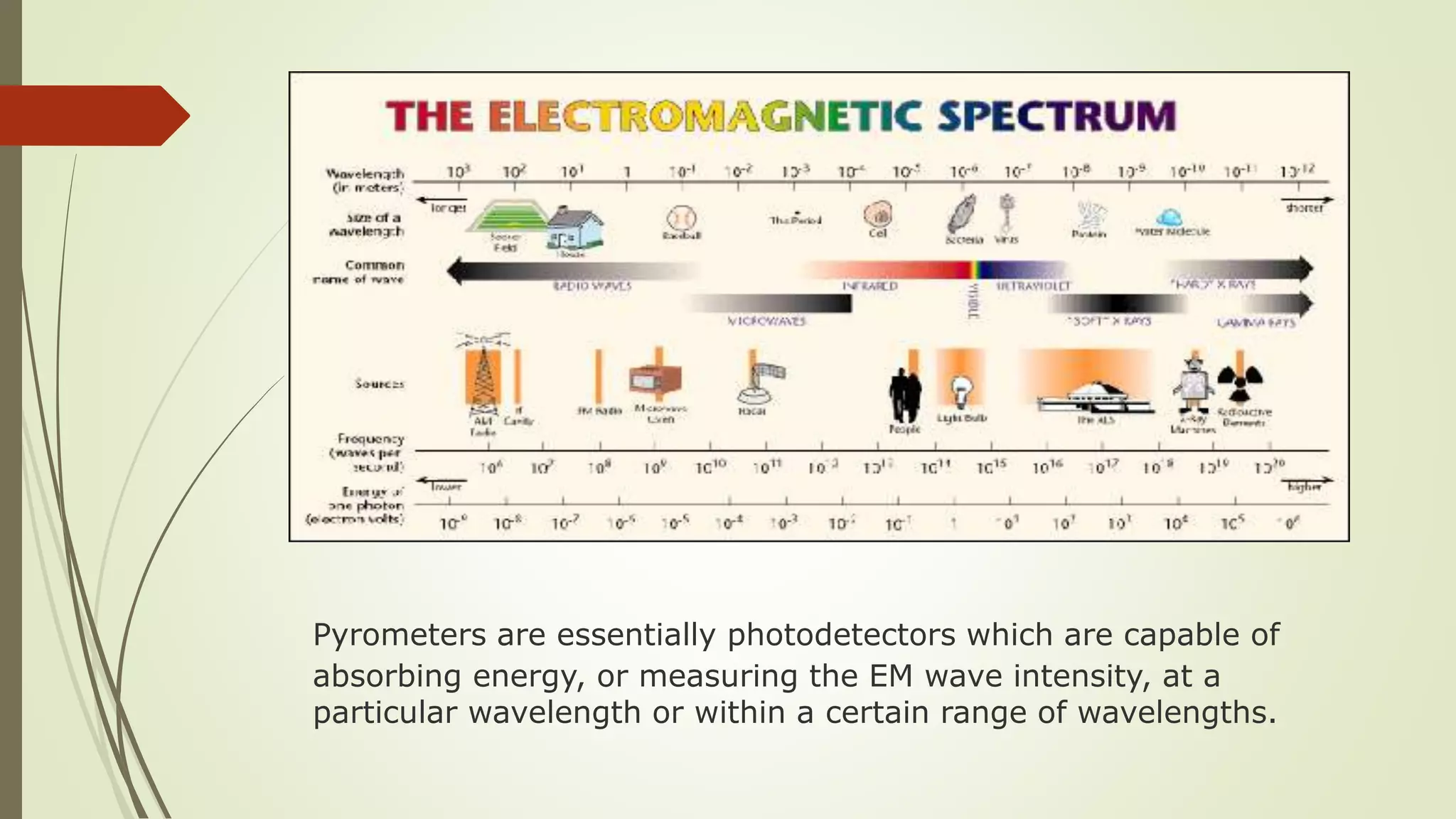

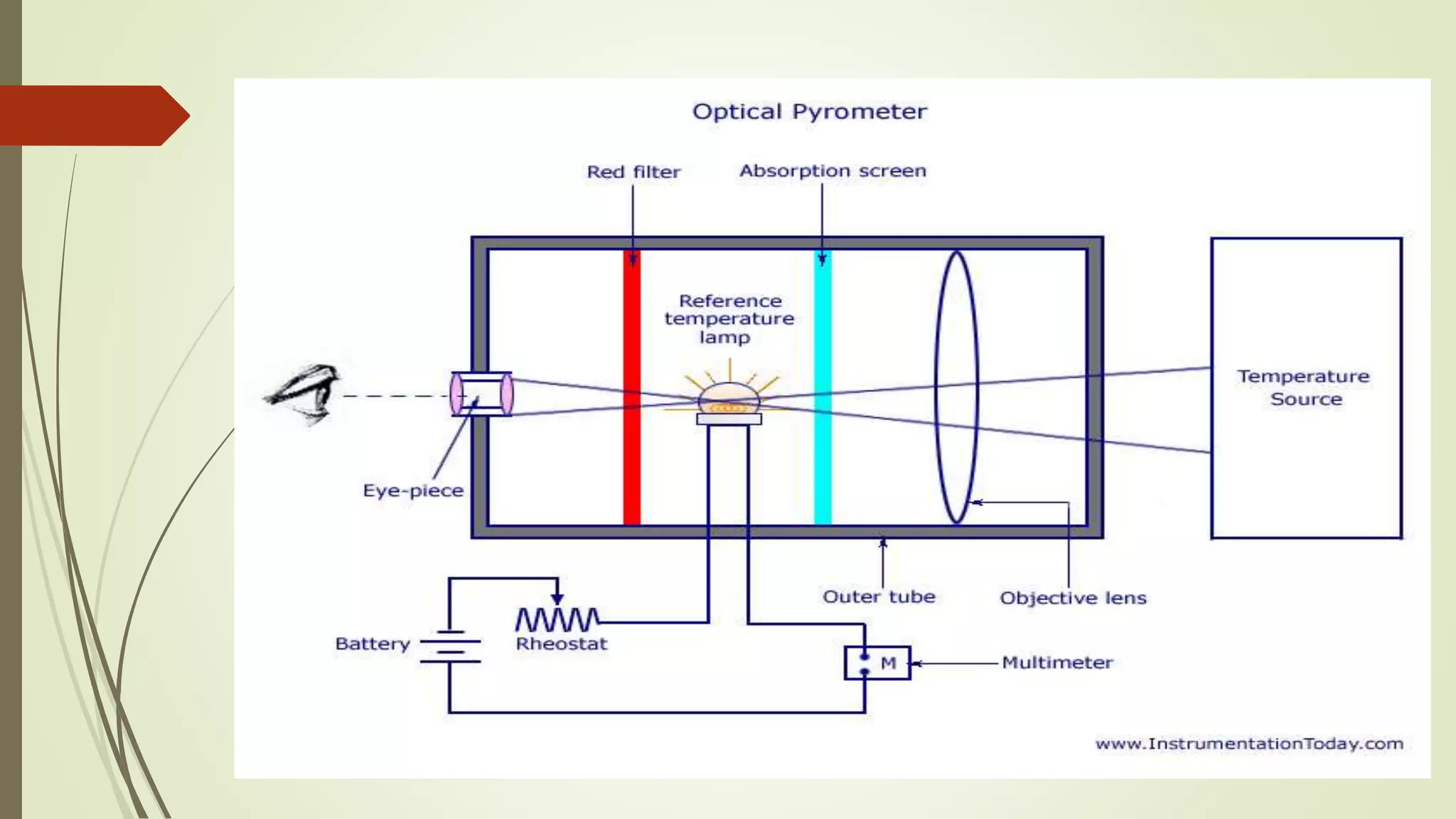

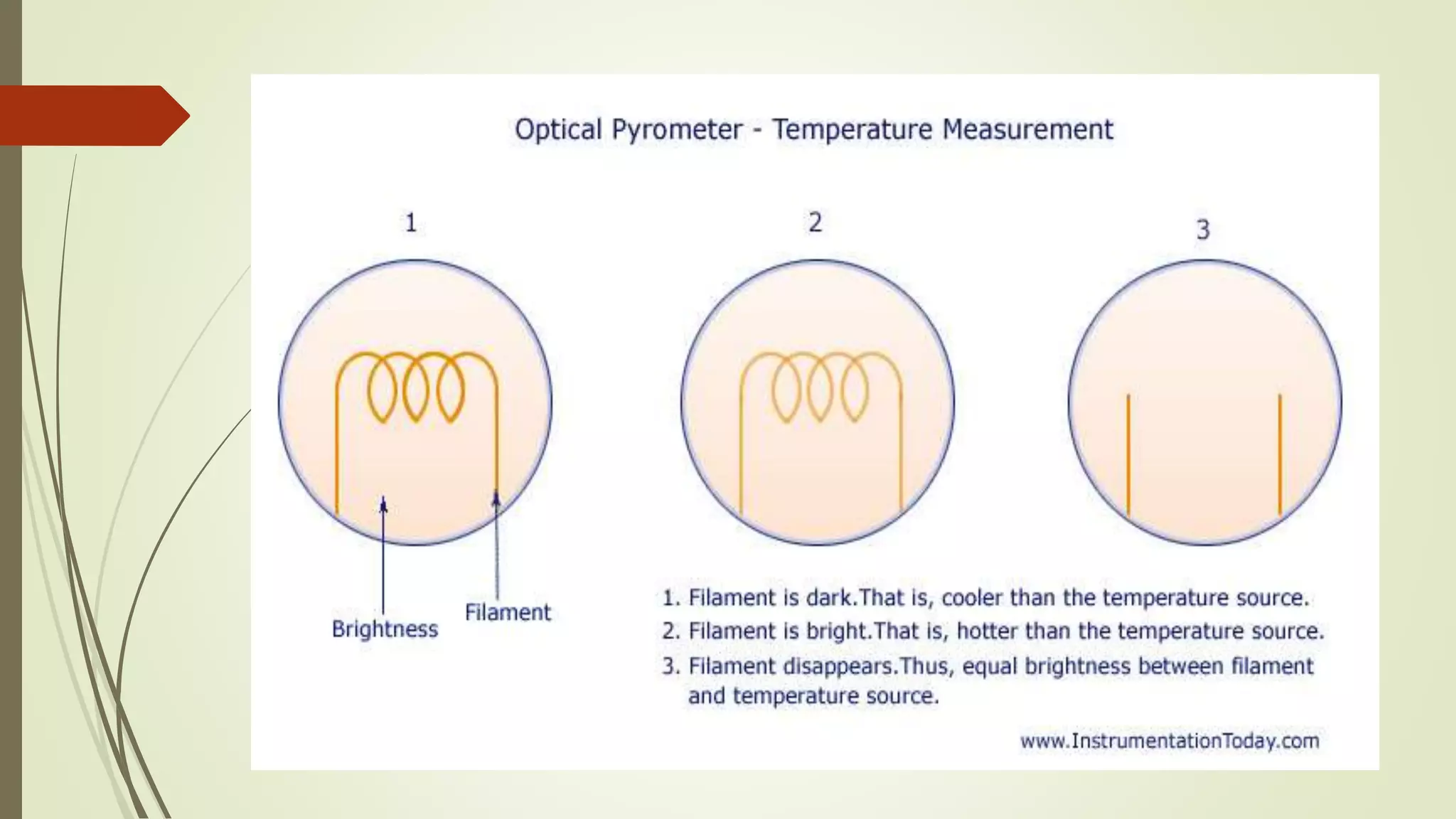

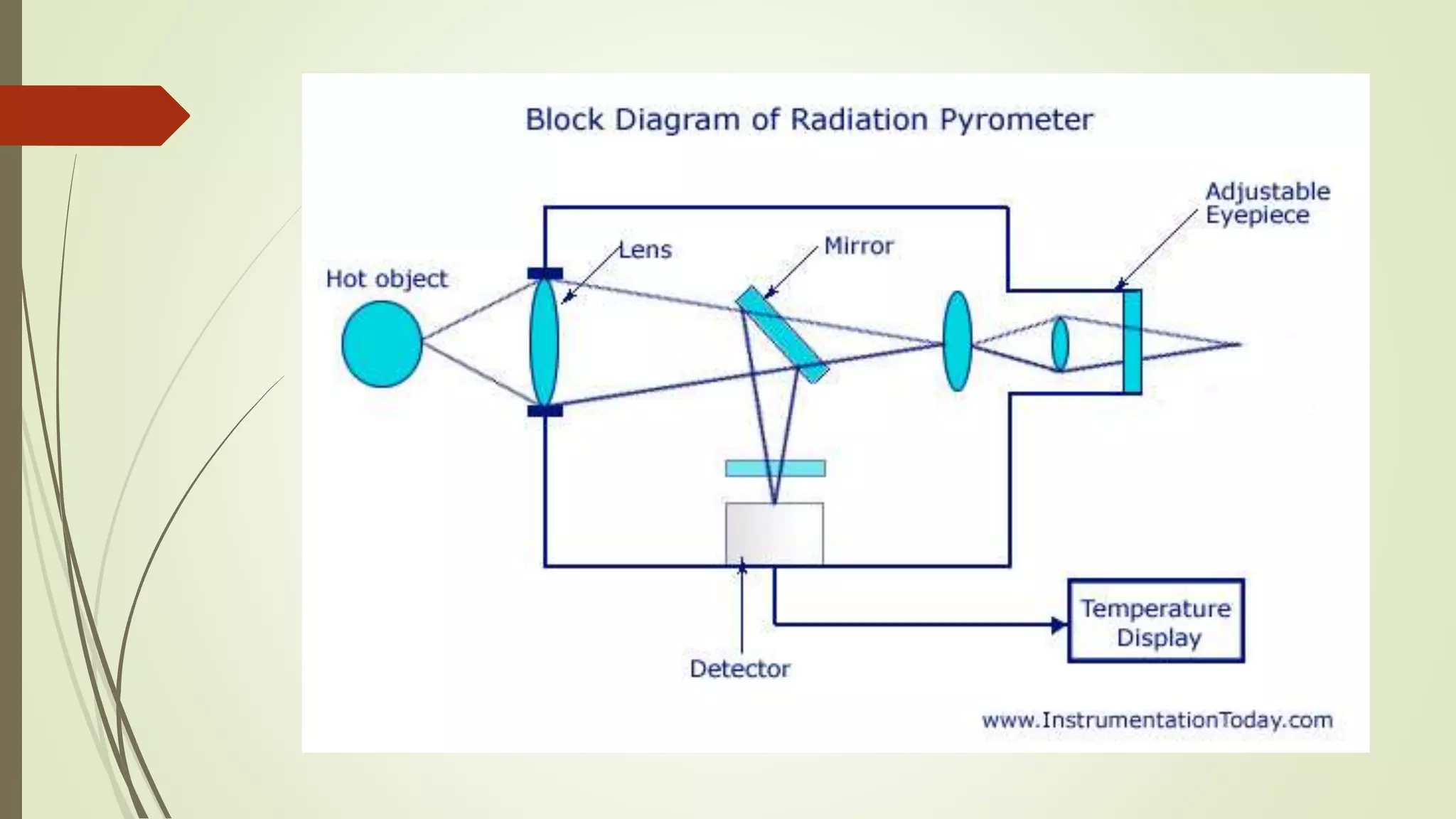

A pyrometer is a device used to measure high temperatures by detecting thermal radiation emitted from an object's surface. The first pyrometer was invented by Josiah Wedgwood to measure temperatures in his kilns. Modern pyrometers work by focusing thermal radiation onto a detector, and the detector's output signal is related to the object's temperature through Stefan-Boltzmann law. There are two main types of pyrometers: optical pyrometers which use manual measurements by comparing an object's brightness to a calibrated lamp, and radiation pyrometers which can measure higher temperatures by detecting infrared wavelengths between 0.7-20 microns.