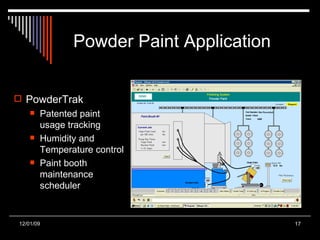

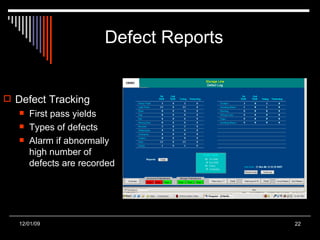

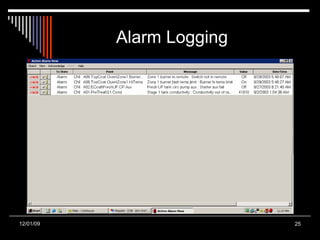

The document discusses a control system for a customized metal finishing process. It describes various modules and controllers that make up the control network, including universal input/output modules, DCS controllers, and specialized controllers for pretreatment, wastewater treatment, air management, and more. It then outlines several areas where implementing process control can reduce costs, such as controlling chemical levels, mechanical variables, conveyors, ovens, parts tracking, and various painting processes.