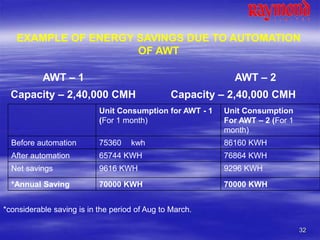

This document discusses automation in manufacturing through several case studies from Raymond Ltd. It describes automating rope scouring machines, chemical dispensing systems, and air washer towers. Automating these processes improved consistency, reduced costs through lower chemical, water and energy usage, minimized human errors, and made process monitoring and fault diagnosis easier, leading to increased productivity and quality. The case studies demonstrate how automation can improve efficiency even with older equipment.