Cascade Finishing Systems (CFS) provides comprehensive engineering solutions, specializing in project management and turnkey services for the automotive and general industry sectors. Their services include the design and construction of paint and powder coating plants, electrical installations, and utility systems, backed by a team of experienced professionals. CFS aims to deliver innovative, cost-effective, and energy-efficient practices while emphasizing sustainability in their projects.

![CFS was established with Prime Objectives of setting milestones of

excellence in all type of Engineering Consultations, Execution &

Commissioning .

We provide Engineering Services for Automotive and General Industries Area

having business approach in Engineering and consultation, Project

Management & Turnkey Solutions. Experienced Engineering professional are

associated with rich experience in providing engineering services to Automotive

and Ancillaries Manufactures.

01 | About CFS [ Cascade Finishing Systems]

Conceptual Engineering & Planning

Plant Ancillaries & Utilities

Low Tension Side– Electrical Works

Interior Design Projects

Paint & Powder Coating Plants & Equipment's

Turnkey Projects – Mechanical & Electrical

Electrical & Automation panels – PLC, AC & DC

Drivers

Project Management](https://image.slidesharecdn.com/cascadefinishingsystems-150326062825-conversion-gate01/75/Liquid-Paint-Shop-Construction-by-Cascade-Finishing-Systems-Mumbai-2-2048.jpg)

![Company Fast Fact

No. of Management Person(s): 3

No. of engineering Staff(s) : 4

No. of Administration staff(s) : 2

No. of Technicians & Workers : 45

01 | About CFS [ Cascade Finishing Systems]..cont](https://image.slidesharecdn.com/cascadefinishingsystems-150326062825-conversion-gate01/75/Liquid-Paint-Shop-Construction-by-Cascade-Finishing-Systems-Mumbai-3-2048.jpg)

![Liquid Paint Shop Construction

1. Spray Booth – Wet Type

2. Spray Booth – Dry Type

3. Air Handling Unit

4. Baking Oven - Conveyorized oven

5. Conveyor system [ Floor / Overhead]

6. Paint Sludge Removal system[PSRS]

Air Pollution Control:

1. Compact Dust Collection system.

Powder Coating Paint Shop construction:

1. Pre-treatment system: preparation for

powder adhesion

2. Powder Coating Spray Booth with

Cyclone & Powder Collection Unit:

3. Conveyorized Baking Unit - Dry - Off

Oven/Curing Oven.

LT Electricals

1. Control Panels – Automation, PLC,

AC&DC Drives, APFC Panel

2. Cable & Cable Tray works

3. Installation and commissioning

4. Fire Fighting Pumps Control Panel

5. Power Distribution Panels

6. Water Supply System – Domestic &

Flushing

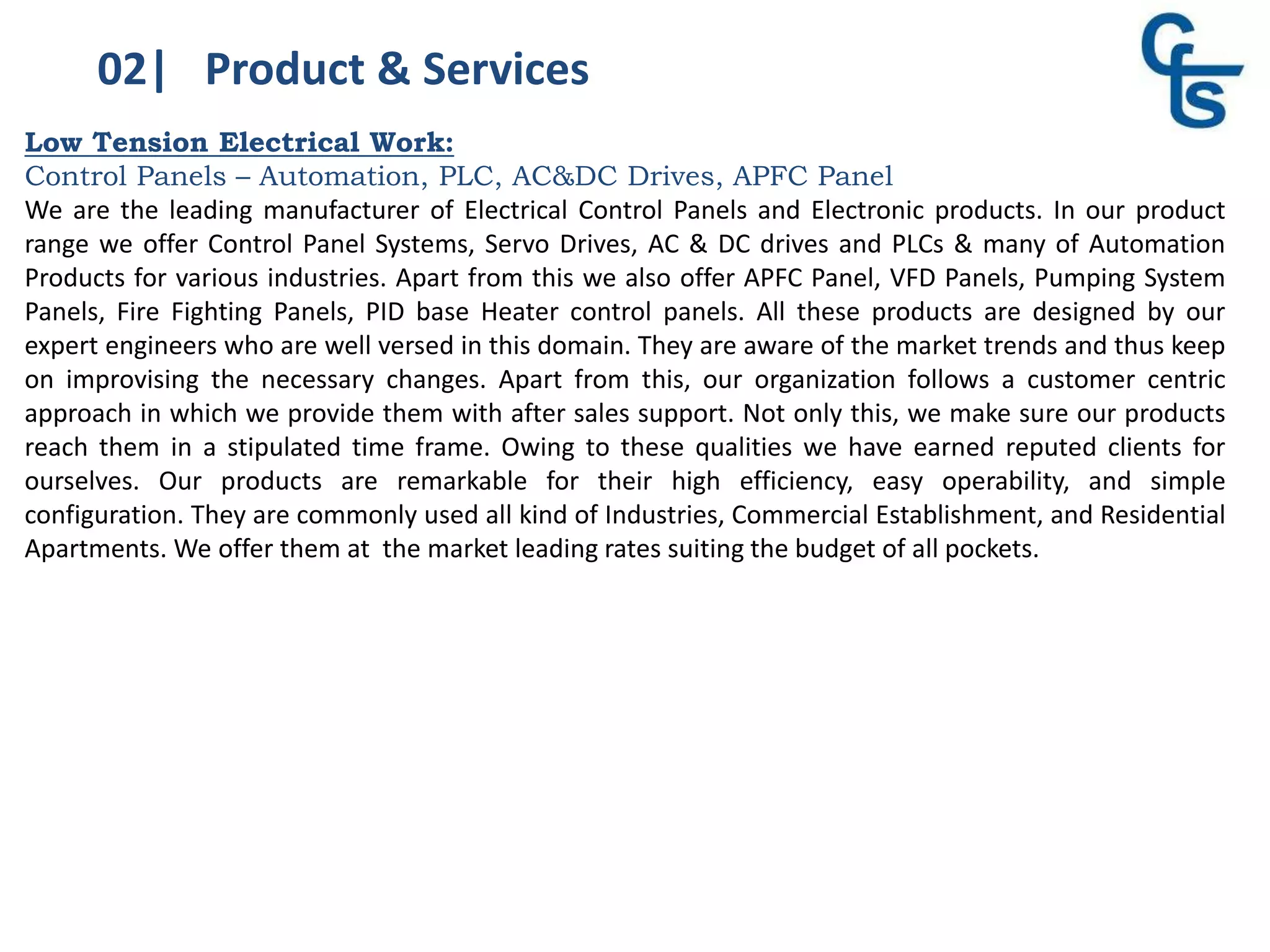

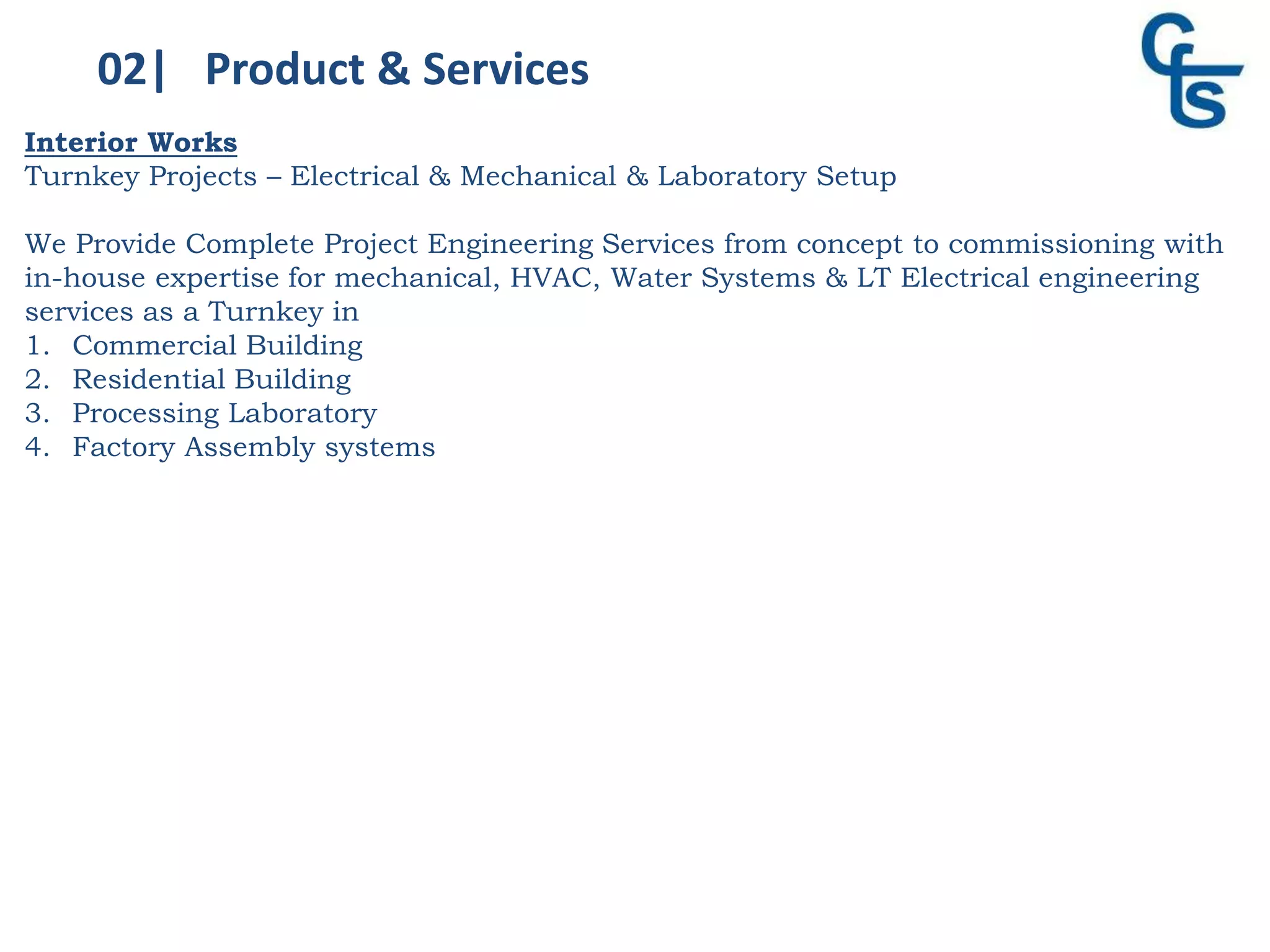

Interiors Works:

1. Turnkey Projects – Mechanical &

Electricals

2. Laboratory Set-up

Plant Ancillaries & Utilities:

1. Air Compressor, Dryer, Filter

2. RO/DM Water Unit

Project Management:

1. Total Project Management

01| Products](https://image.slidesharecdn.com/cascadefinishingsystems-150326062825-conversion-gate01/75/Liquid-Paint-Shop-Construction-by-Cascade-Finishing-Systems-Mumbai-5-2048.jpg)

![02| Product & Services

Liquid Paint Shop Construction Spray Booth - Dry Filter Type

Environmentally Safe Each Industrial Dry Filter Spray Booth is designed to meet or exceed safety

requirements. And to protect those who work in any general manufacturing spray environment, while

also protecting the environment outside. Our dry spray booth will efficiently remove paint overspray

while maintaining uniform air flow throughout the work area.

MOC: High Grade SS/MS Galvanised sheets with proper structural support.

Highest Quality Finish Our dry filter spray booths for creating an environment that allows painters to

apply the highest quality finishes to their products. Our dry filter booth will effectively remove airborne

paint particles, through our custom engineering process, to ensure laminar air flow. Filter media shall be

Paper Filters, GI Baffles filters, Paint arrestor media [Filter Class EU 3/4]

Flexible and Adaptable You’ll discover that we custom design our industrial-type dry filter spray booths

to whatever your finishing applications might be. From open face booths for batch production, to high

production, conveyorized dry spray booth models. Adapting front filter doors, air make-up systems and

special spray booth controls are just a few ways that we can engineer a custom dry spray booth for you.

Lower Operating Costs We use higher efficiency– components and designs. We offer energy efficient

components from VFD drives manually setting with Differential Pressure indicators, high efficiency

motors, FLP lighting, Spray booth Interlock with Compressed air, which result in lower operating costs,

Paper filter, and paint arrestor media.](https://image.slidesharecdn.com/cascadefinishingsystems-150326062825-conversion-gate01/75/Liquid-Paint-Shop-Construction-by-Cascade-Finishing-Systems-Mumbai-6-2048.jpg)

![02| Product & Services

Liquid Paint Shop Construction Spray Booth - Wet Type

Highest Quality Finish and Environmentally Safe Our water wash spray booth provides an extremely

efficient means for removing paint particles from the exhausted air by using water as a filtration medium

by scrubbing. Water wash booths are utilized for high volume paint usage. In addition, water wash

booths handle a larger variety of paints as compared to dry filter booths, with a wider range of

viscosities and drying speeds of the Paints, as a package with Auto - Dosing Systems.

Flexible and Adaptable Our water wash booths are designed for many finishing applications. We offer in

open face with conveyorized types. Adapting plenum filters, air make-up systems, sludge de-watering,

and special spray booth controls are just a few ways that we can engineering a custom-way of water

wash spray booth for you. Also, Auto-scrubbing system will consider to custom design the same.

MOC: High Grade SS/MS Galvanised sheets with proper structural support.

Scrubbing Unit: Refer our “ Paint Sludge Removal System”[PSRS]](https://image.slidesharecdn.com/cascadefinishingsystems-150326062825-conversion-gate01/75/Liquid-Paint-Shop-Construction-by-Cascade-Finishing-Systems-Mumbai-8-2048.jpg)

![02| Product & Services

Liquid Paint Shop Construction Paint Sludge Removal System

All recirculating paint booth systems require some means of removing the detackified / coagulated paint

overspray, which was generate from Water Spray Booth. If the paint solids are allowed to build up

without removal, the system will begin to suffer from a countless of problems, including: Sludge build-

up on booth equipment – resulting in booth balance issues, loss of water flow in critical areas in the

system, high maintenance costs, etc. Odours emanating from bacteria hiding in the sludge. High

suspended solids in the booth water – could lead to excessive foaming High costs to remove

accumulated sludge – sludge may be wet/hazardous We offers the scrapping mechanism with float

pump to dispose the sludge very frequently. Our Paint Sludge Removal System[PSRS], consists of a

series of Chamber are used to collect the water from Spray Booth return Stream. The over spray from

Component gets collected by the water screen and Booth Sludge water tank. The Paint Contaminated

water contains the Paint Sludge and other particles that are collected in a sludge chamber from the Paint

booth where it is treated and clarified by the chemical agent called Coagulant & Flocculent. Then the

Paint sludge float over the layer of water which remove mechanical means of scrapper and the water

shall deliver to the common Waste Water Treatment Plant.](https://image.slidesharecdn.com/cascadefinishingsystems-150326062825-conversion-gate01/75/Liquid-Paint-Shop-Construction-by-Cascade-Finishing-Systems-Mumbai-12-2048.jpg)

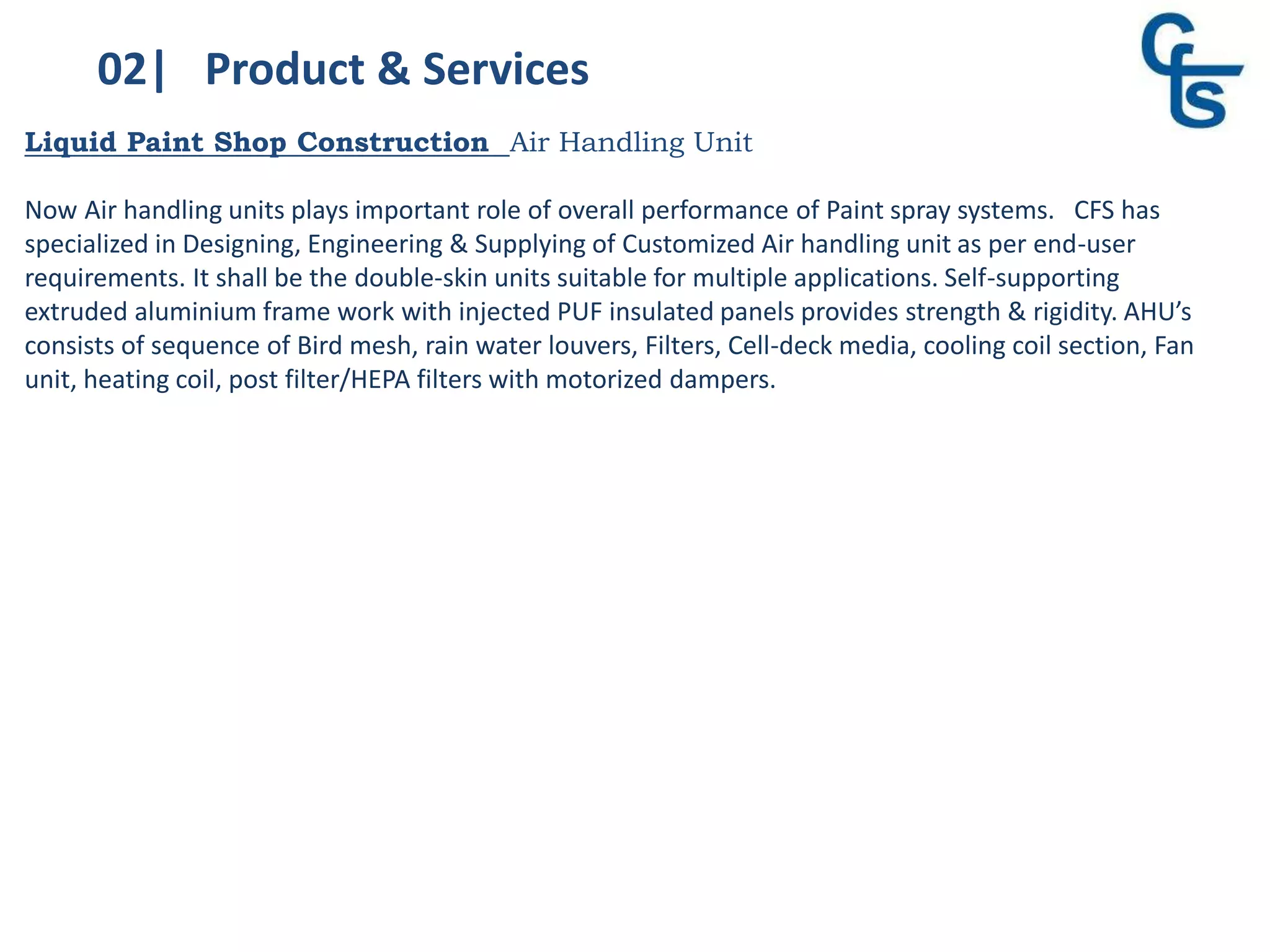

![02| Product & Services

Plant Ancillaries & Utilities

Air Compressor, Receiver with Dryer unit

We Provide Complete Design & Supply for actual compressed air[in CFM] requirement

for over-all Plant also installation and commissioning support for the same systems.](https://image.slidesharecdn.com/cascadefinishingsystems-150326062825-conversion-gate01/75/Liquid-Paint-Shop-Construction-by-Cascade-Finishing-Systems-Mumbai-21-2048.jpg)

![03| Project Management

PM Contract

TM/BM Contract

Spare Management

Production Support

Feasibility

Analysis

Basic Concept

and Design

Detail Design

and Planning

Construction

and Project

Management

Project

Commissioning

Production

Support

Parts to be painted

Production Volume/model

Paint Application data

Location analysis

Current Practice

Budget analysis

Basic Drawing [Plan View]

Capacity Calculations

Production Area

Process Design

Investment Cost

Basic Detail - Equipment's

Project Bifurcation

Detail Site Survey

As Build Drawing Provided

Details of Each Equipment

Project Schedule & Milestone

Organisational Chart

KOM-Vendors

Weekly Project Meeting

Weekly Project Follow-up

Project Change Management

Additional Works Defined

Works/Equipment Inspection

Production Trial

Testing Report

Project Hand-over

Manuals Hand-over

As-built drawing Hand over](https://image.slidesharecdn.com/cascadefinishingsystems-150326062825-conversion-gate01/75/Liquid-Paint-Shop-Construction-by-Cascade-Finishing-Systems-Mumbai-24-2048.jpg)

![04| Engineering Services

Turkey Services [Concepts – Commissioning – Validation]

Launching Support

Feasibility Study – Basic Engineering/Conceptual & Detail Engineering

Mechanical & Electrical Services

HVAC & Shop Ventilation

Building Interiors

Fluid Piping Systems

Processing Industry/Lab Ventilation

Process Equipment & Shop Utilities

Fume & Dust Extraction Systems [FES & DES]

Paint Spray Booth – Dry/Wet/Temperature Controlled/RH Controlled

Project Management Consultancy](https://image.slidesharecdn.com/cascadefinishingsystems-150326062825-conversion-gate01/75/Liquid-Paint-Shop-Construction-by-Cascade-Finishing-Systems-Mumbai-25-2048.jpg)

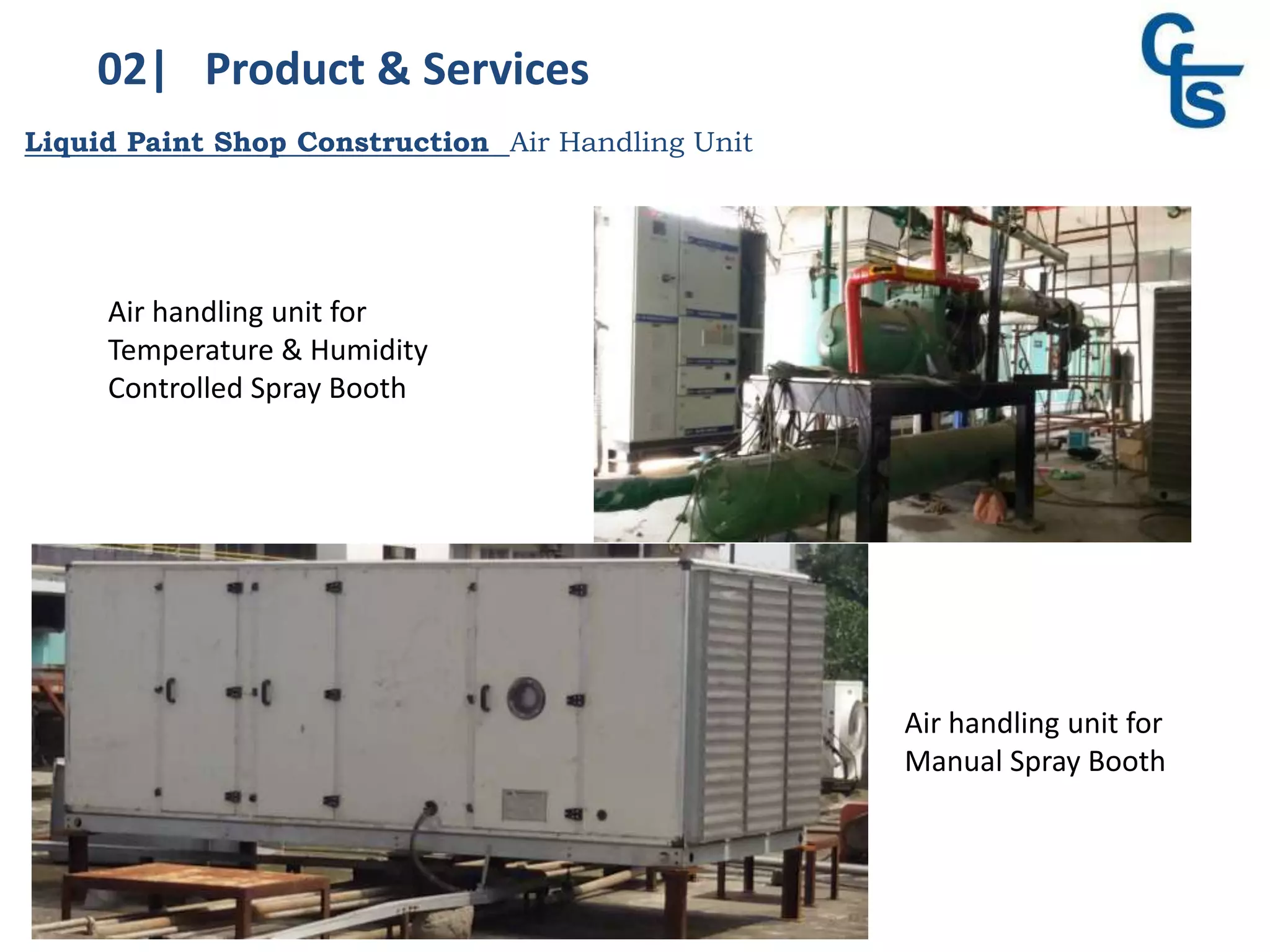

![08| Projects Executed – LT Work R&D Centre, PPGAP, Turbhe

Grid Structure Work – 1800Sq.mt

DB with cabling Work

MPDB & APFC installation with cabling [LT Side]

45 TR Water-cooled Chiller for Temp & RH Controlled

Spray Booth](https://image.slidesharecdn.com/cascadefinishingsystems-150326062825-conversion-gate01/75/Liquid-Paint-Shop-Construction-by-Cascade-Finishing-Systems-Mumbai-27-2048.jpg)