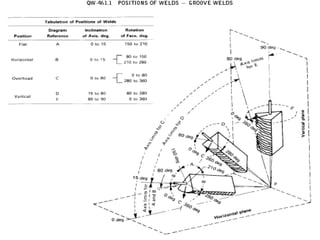

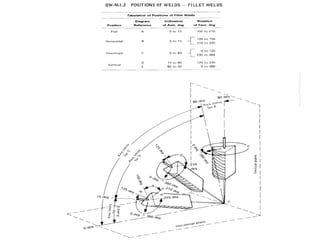

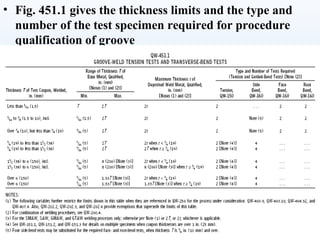

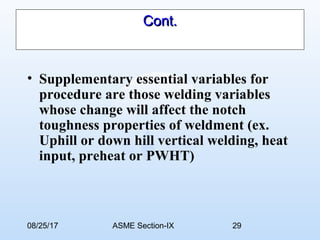

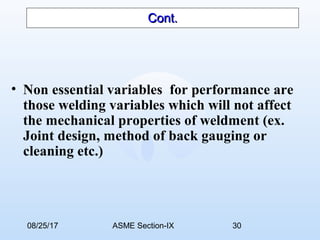

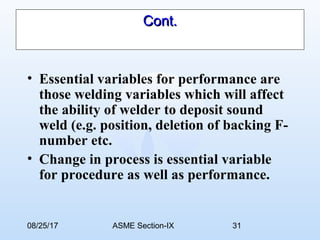

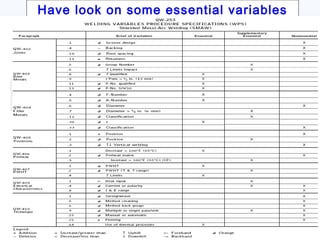

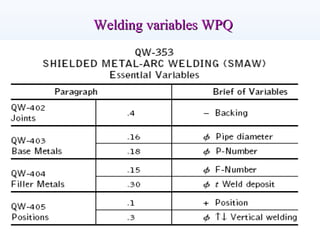

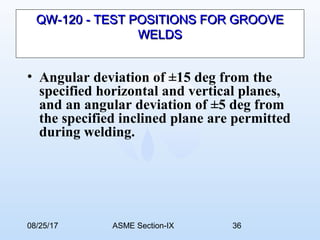

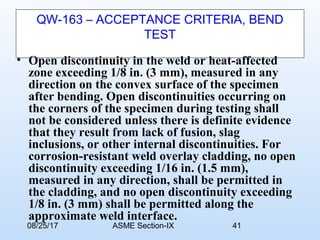

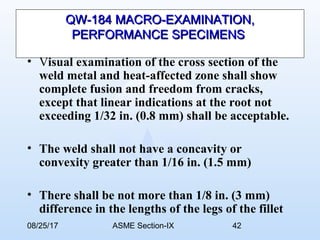

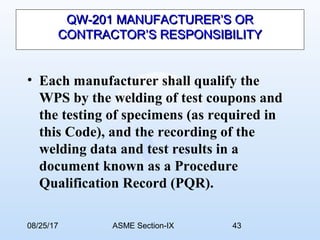

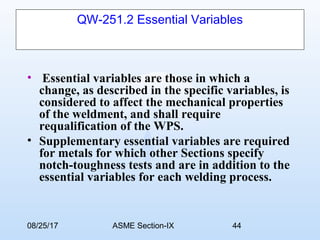

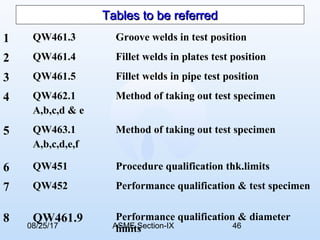

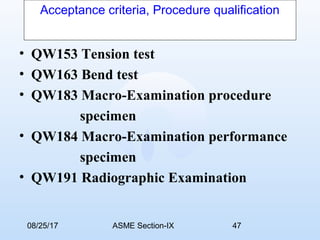

ASME Section IX relates to welding qualifications and welding procedure specifications (WPS). It has requirements for qualifying welders and welding procedures. A WPS defines the welding variables for a procedure, while procedure qualification records (PQR) document the testing of welds made according to the WPS to ensure they meet mechanical property requirements. ASME Section IX specifies the welding positions, types of tests including tension tests and bend tests, acceptance criteria for test results, and classification of welding variables as essential or non-essential to determine whether requalification is needed if variables change.