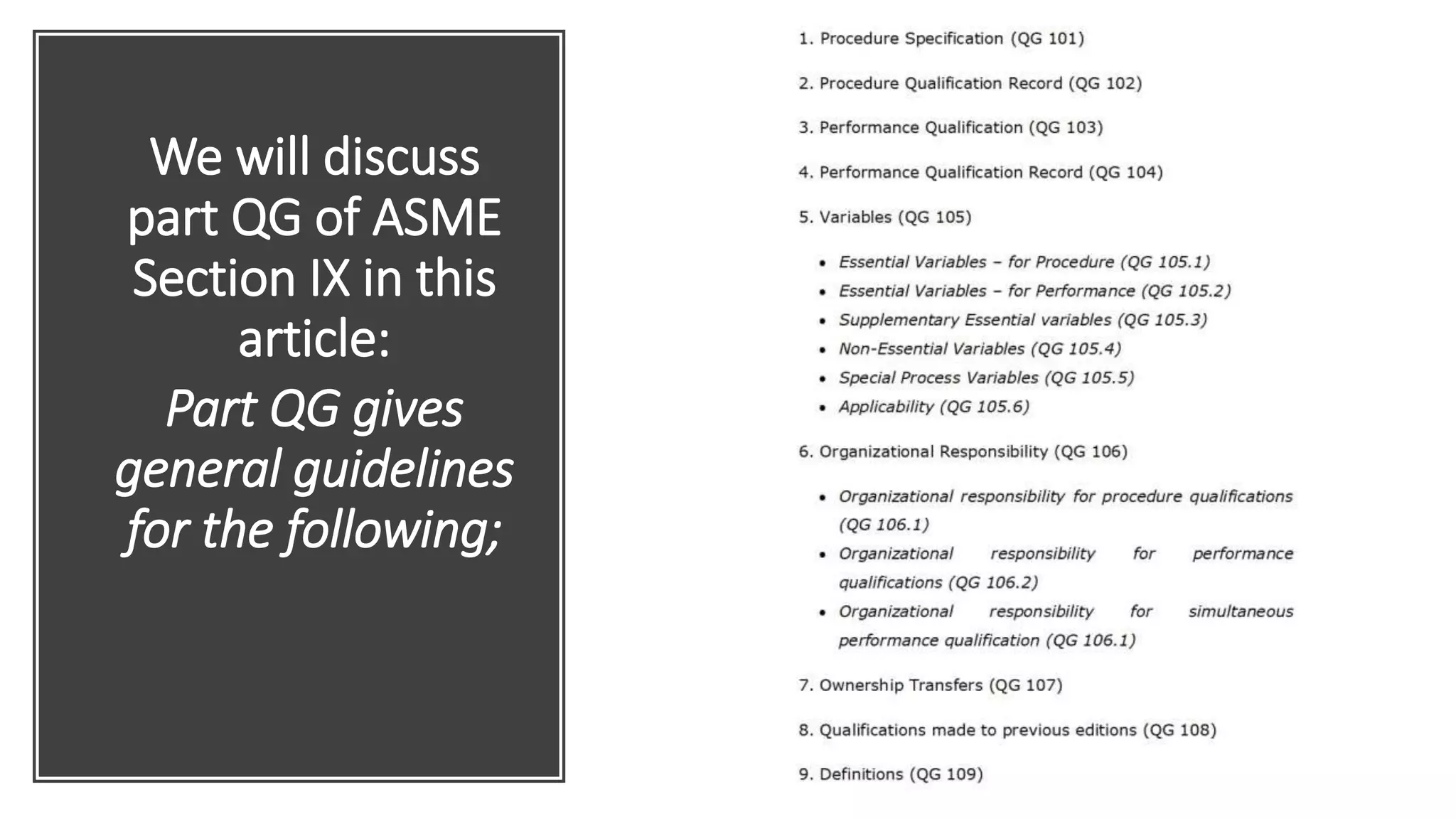

The document summarizes the key parts and requirements of the ASME BPVC Section IX code related to welding. It describes that Section IX is divided into four parts, including Part QW for welding. Part QW further divides welding into five articles related to general requirements, procedure qualification, performance qualification, welding data, and welding procedure specifications. The document then focuses on explaining the requirements in Part QG, including procedure specifications, procedure qualification records, performance qualification, variables, and organizational responsibilities.