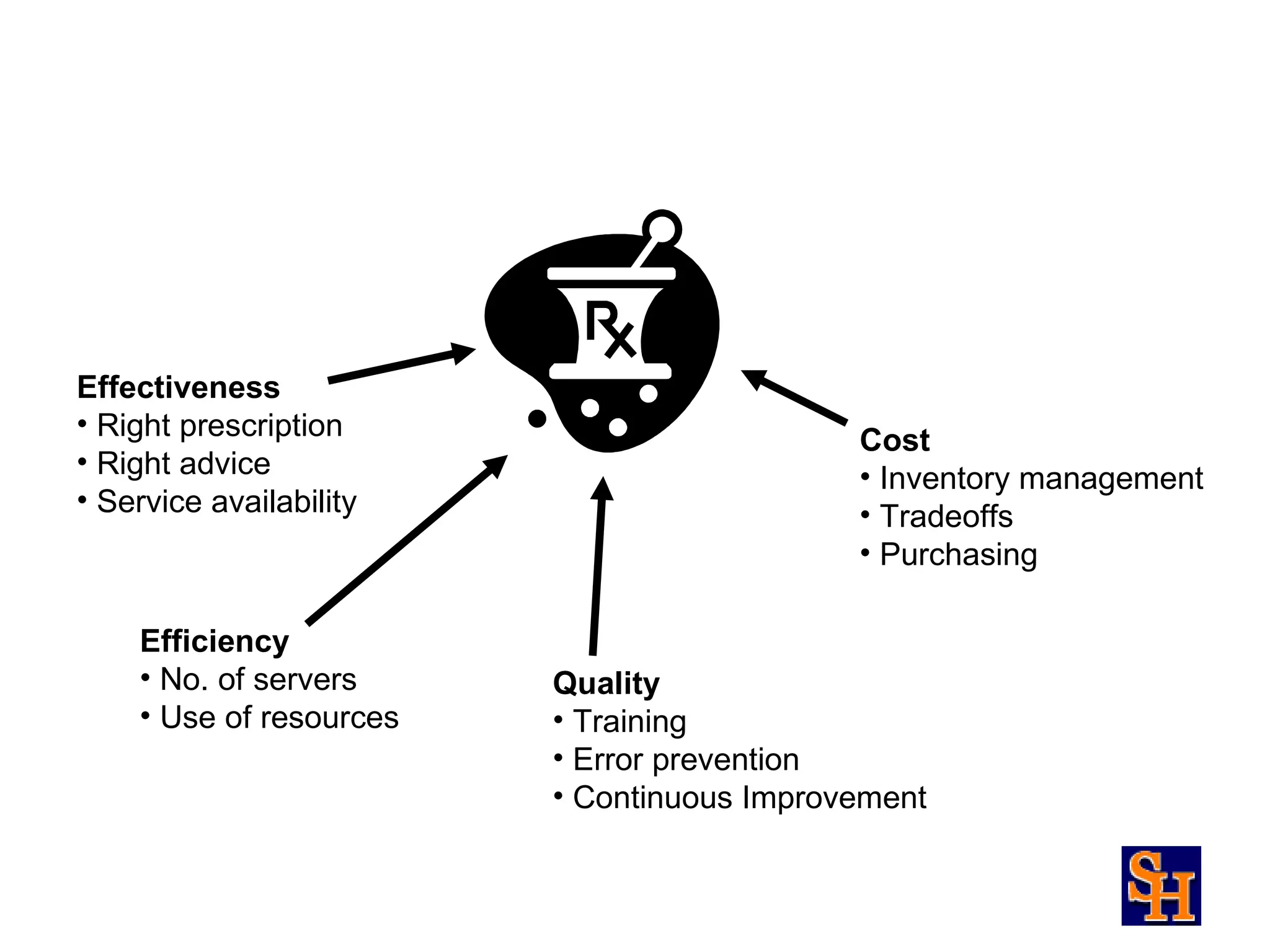

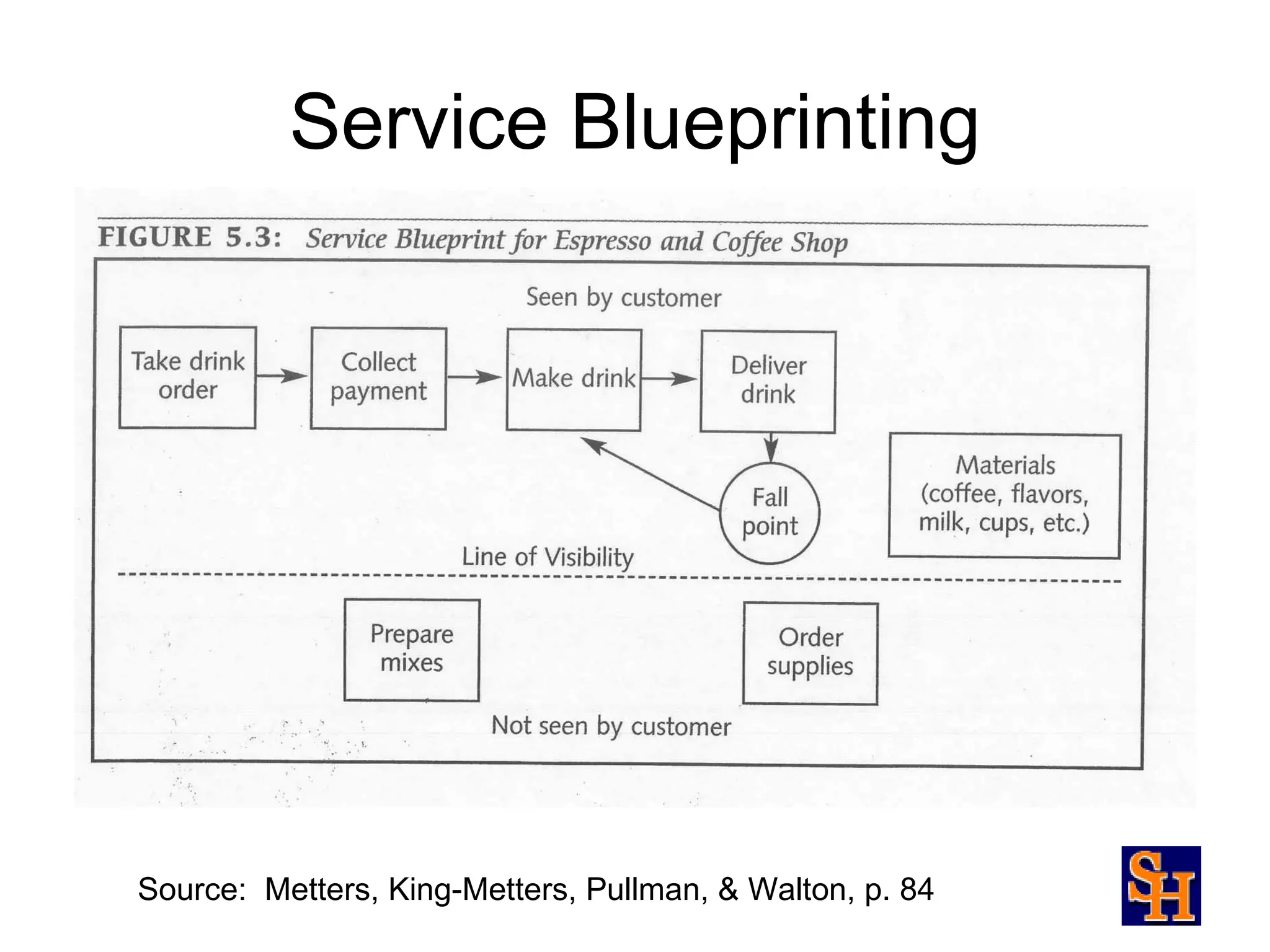

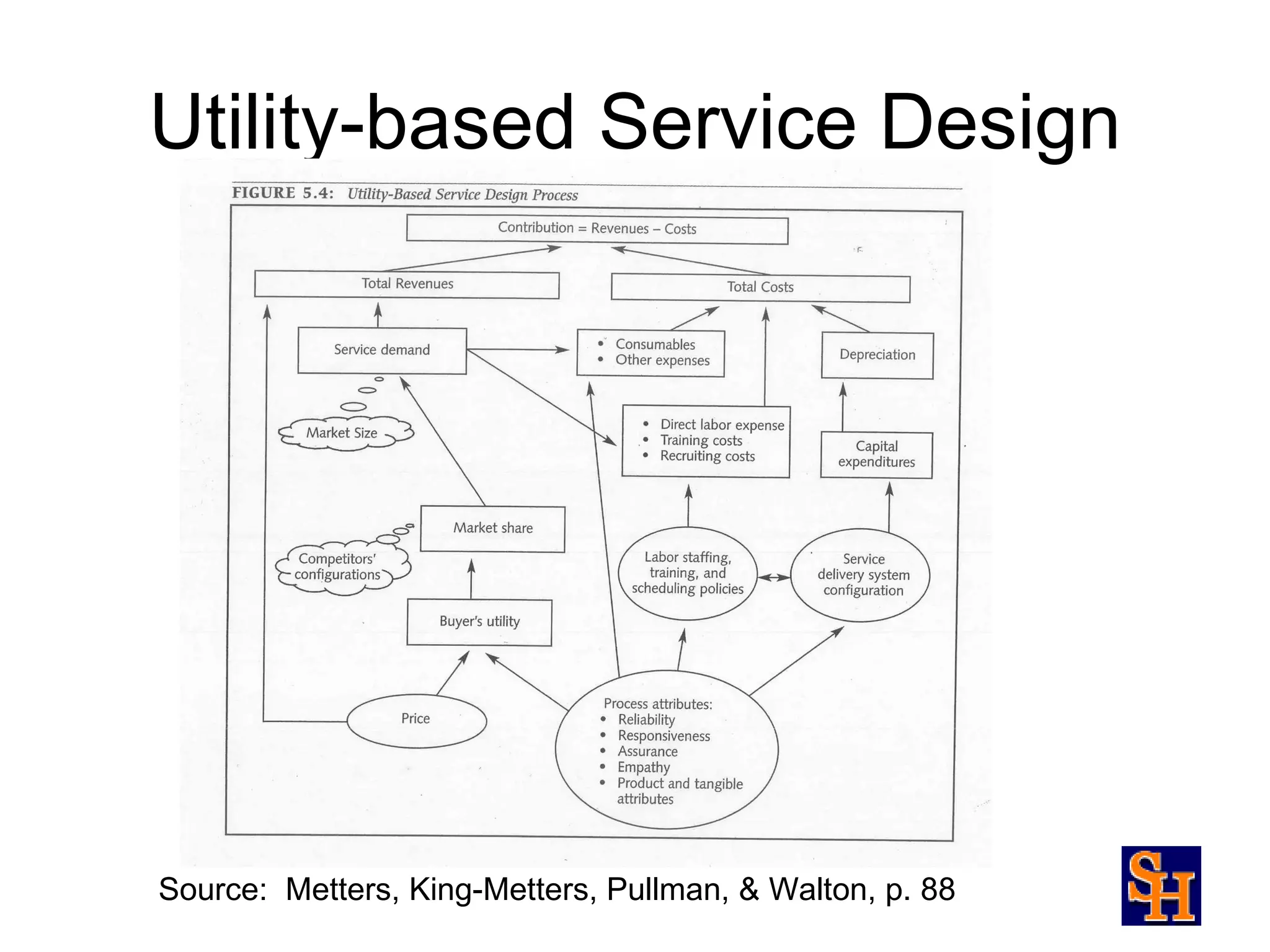

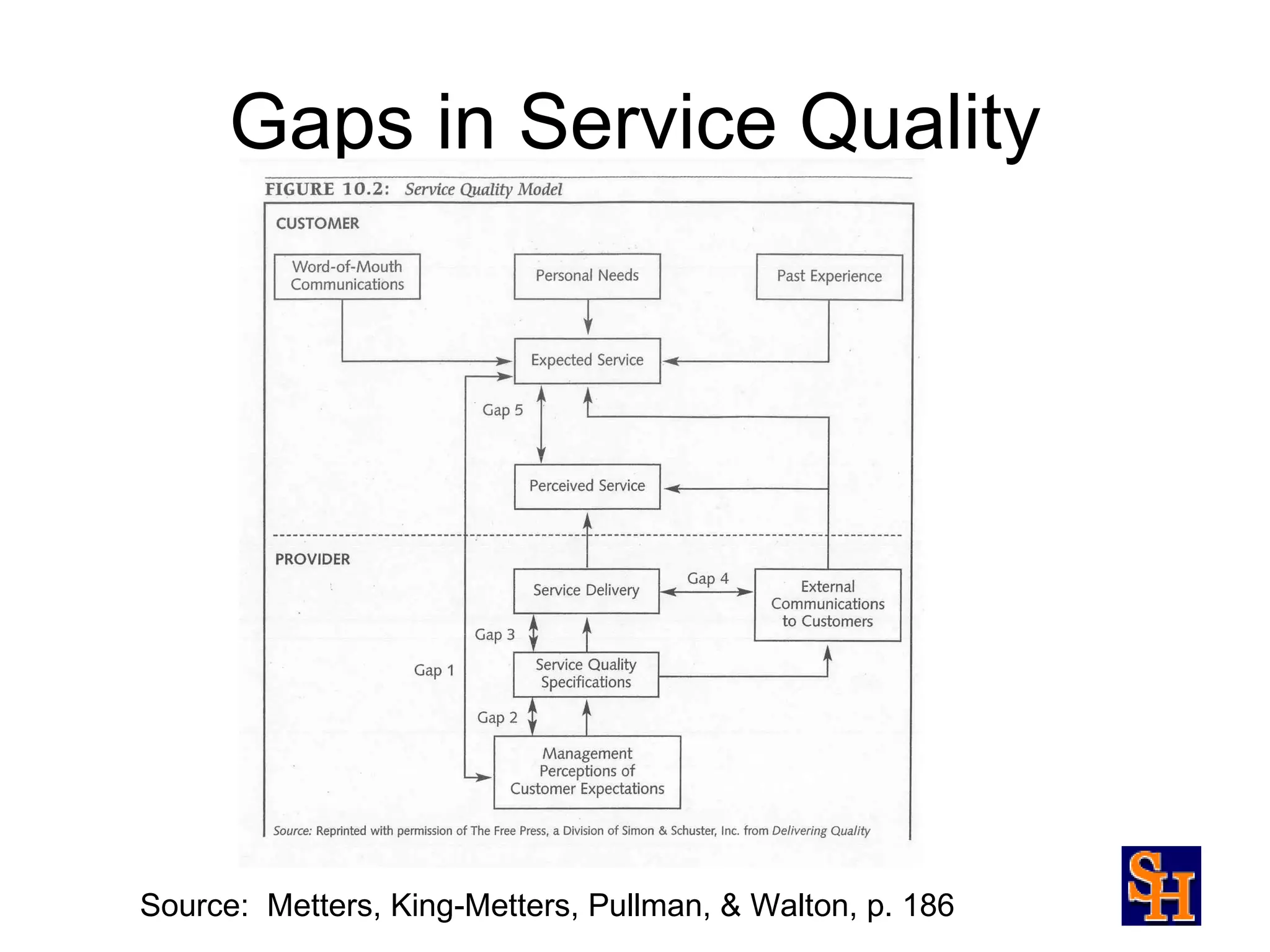

Service operations management deals with the same key areas as manufacturing operations - efficiency, effectiveness, quality, and cost. Both must focus on the right processes, resource usage, training, and continuous improvement. Some unique issues for service operations include new service development using tools like service blueprinting, managing customer experiences, analyzing front and back office processes, service quality using frameworks like SERVQUAL, and yield management of inventory. References are provided on further resources for successful service operations management.