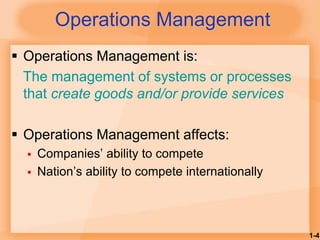

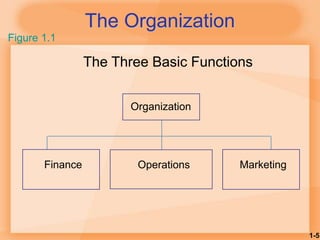

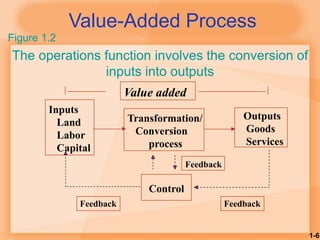

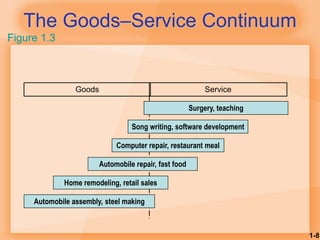

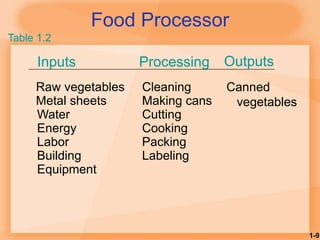

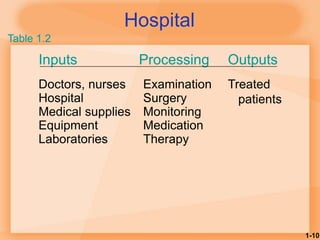

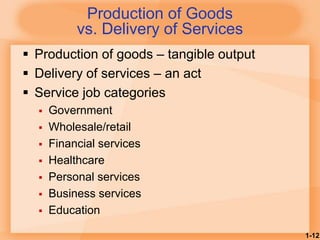

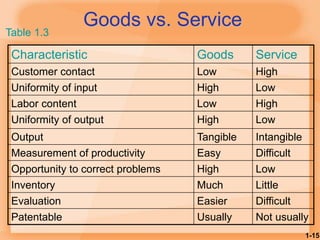

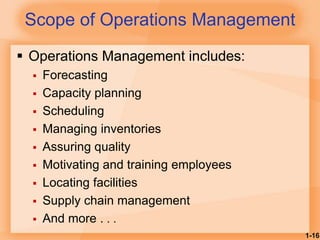

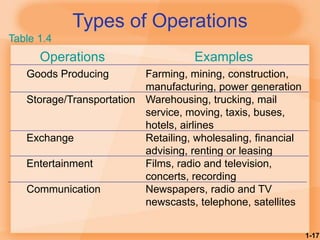

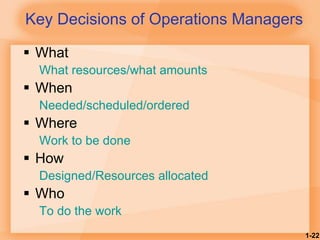

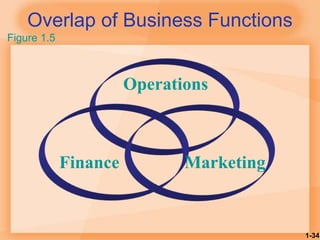

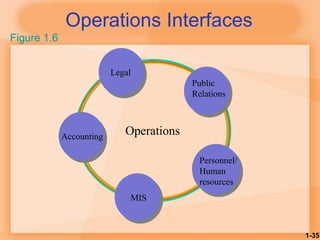

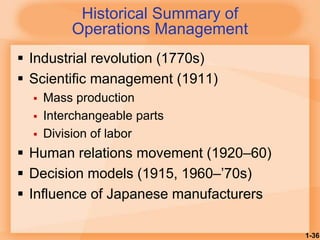

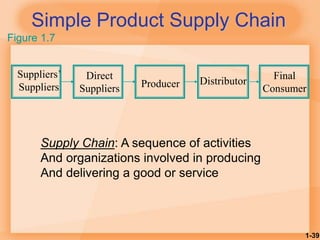

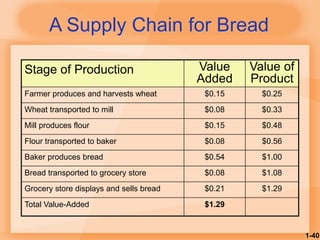

This document provides an introduction to operations management. It defines operations management as the management of systems or processes that create goods and/or provide services. It discusses the three major functional areas of organizations - operations, finance, and marketing. It also compares and contrasts goods production and service delivery. The document outlines several key learning objectives and concepts in operations management, including the value-added process, types of operations, differences between manufacturing and services, decisions made by operations managers, and historical and current trends impacting the field.