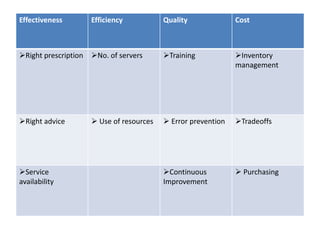

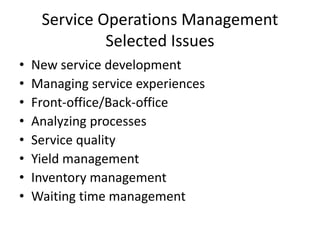

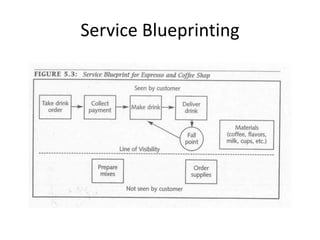

Rahul Ranjan's document discusses key issues in service operations management. It outlines that both service and manufacturing operations focus on efficiency, effectiveness, quality, and cost. It then provides overviews of topics like new service development, managing customer experiences, analyzing processes, service quality, yield management, inventory management, and waiting time management. Specific techniques covered include service blueprinting, utility-based service design, dimensions of service quality, and managing front and back office functions.