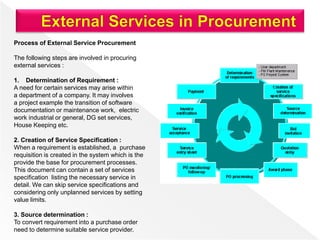

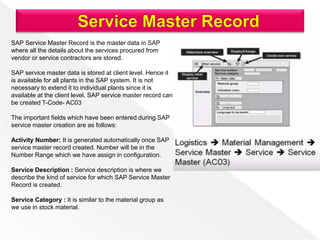

The document discusses the process of procuring external services in SAP. It involves several steps:

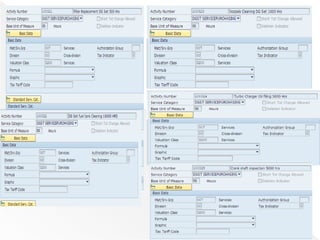

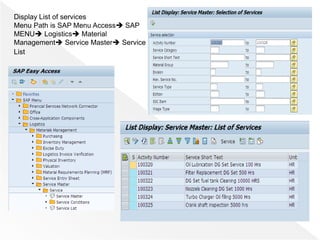

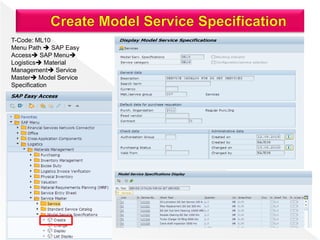

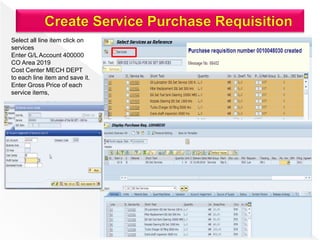

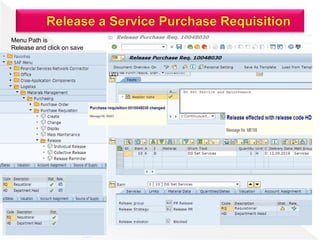

1. Determining service requirements and creating a service specification.

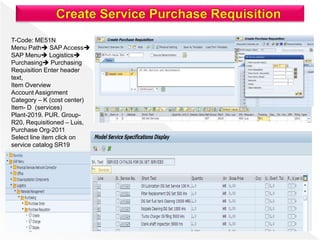

2. Sourcing suitable service providers and sending requests for quotation.

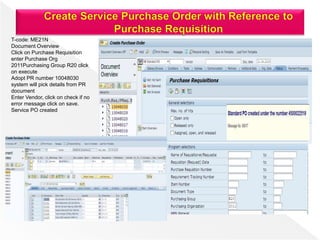

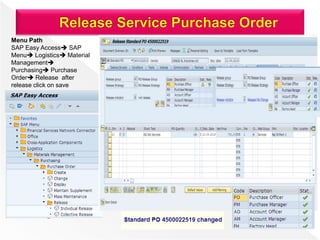

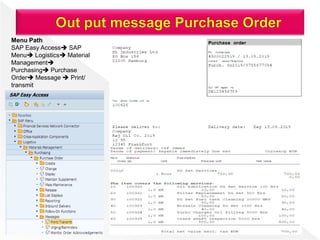

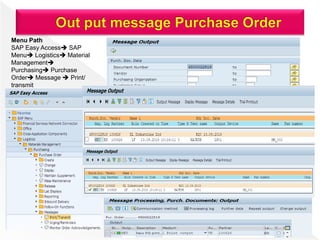

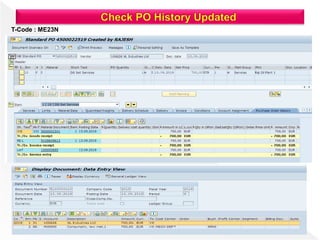

3. Creating a purchase order referencing the requisition or quotation.

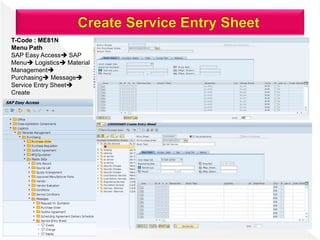

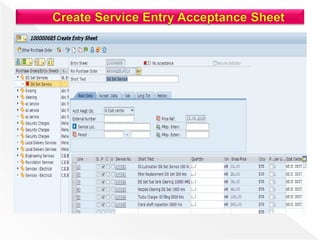

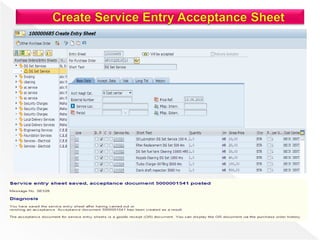

4. Recording service entry sheets against the purchase order and accepting completed work.

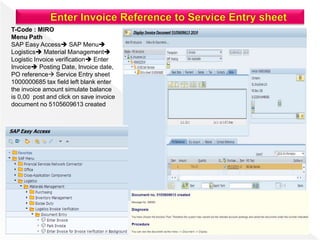

5. Verifying vendor invoices by matching them to accepted service entry sheets.