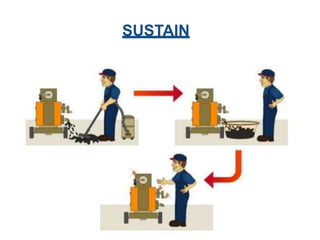

The 5S methodology is a workplace organization method originally developed in Japan that consists of five Japanese words: seiri, seiton, seiso, seiketsu, and shitsuke. The methodology involves sorting, setting in order, shining, standardizing, and sustaining a clean, orderly work environment. It is designed to increase efficiency, quality, and safety through identifying and storing the items used, maintaining the work areas and items, and sustaining the new order through standardization and employee training.