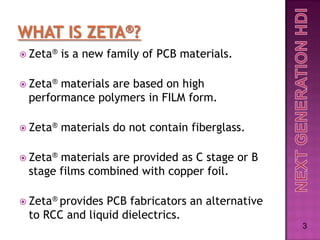

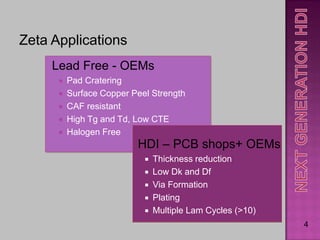

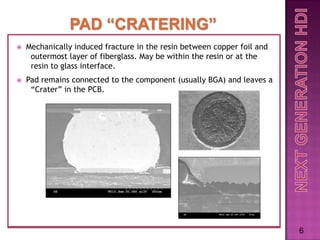

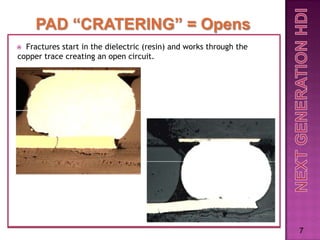

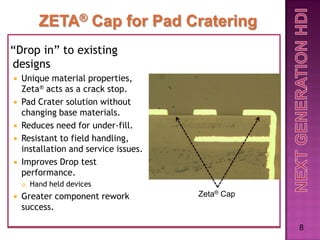

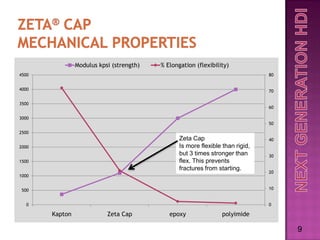

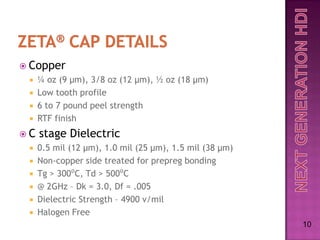

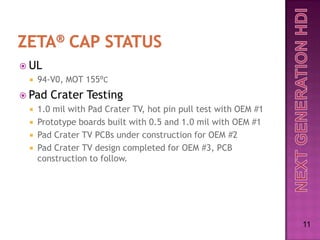

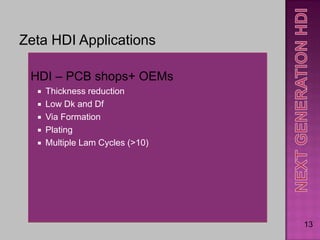

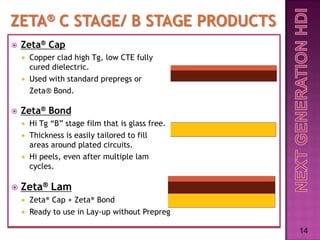

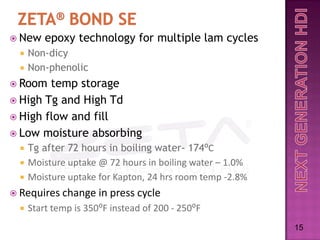

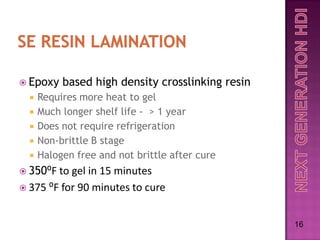

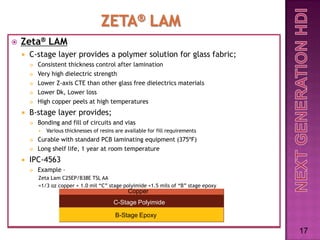

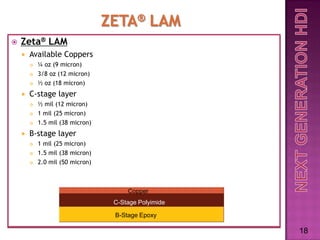

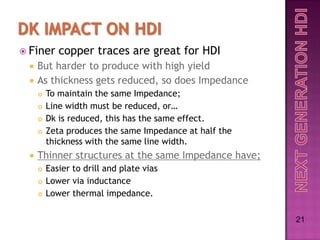

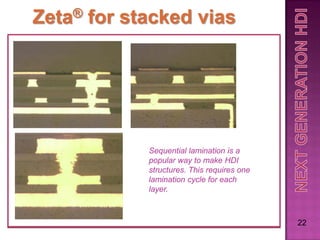

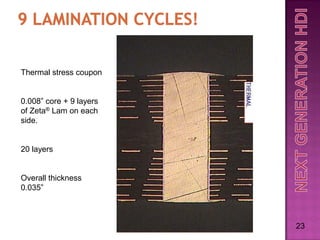

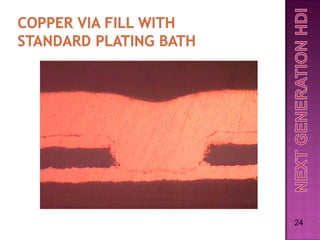

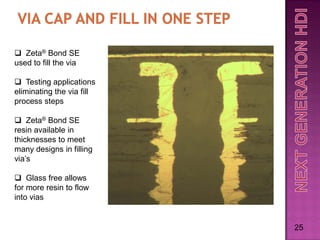

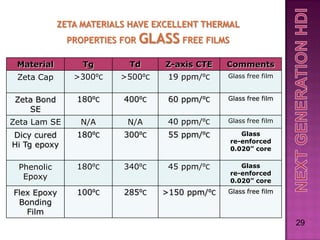

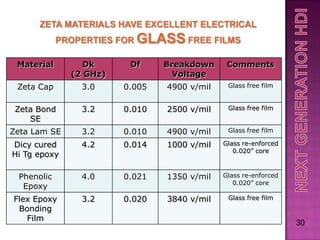

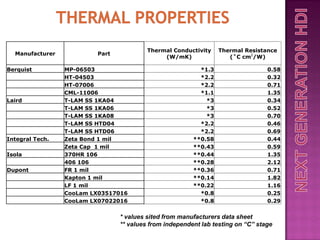

Zeta® is a family of high-performance PCB materials designed without fiberglass, offering alternatives to traditional liquid dielectrics for pad cratering and HDI applications. Zeta® materials, like zeta® cap and zeta® bond, exhibit improved mechanical and thermal properties, facilitating robust designs and effective solutions for electronic manufacturing challenges. Their unique characteristics allow for flexibility in design and processing, particularly in lead-free assembly and high-density interconnects.