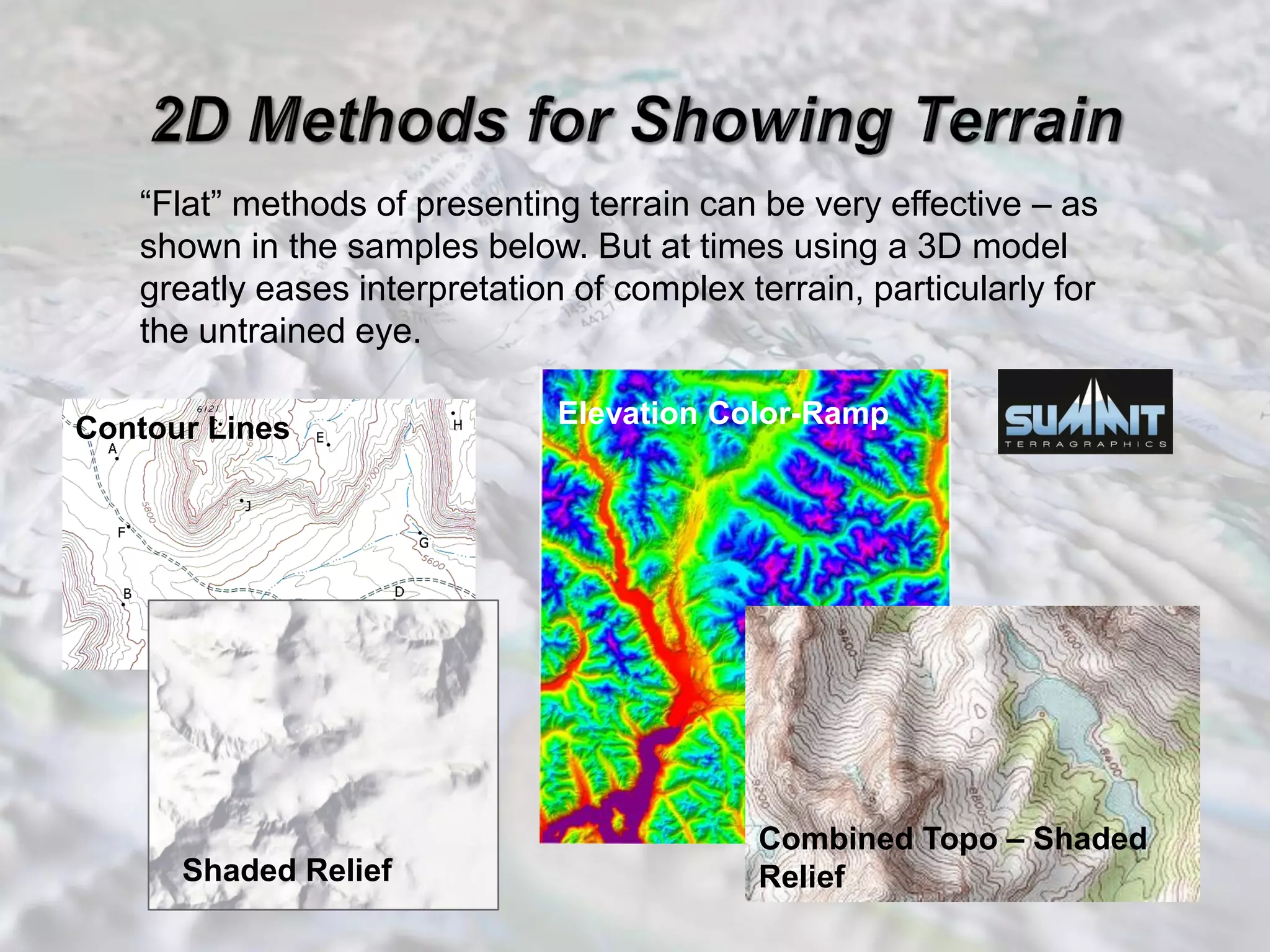

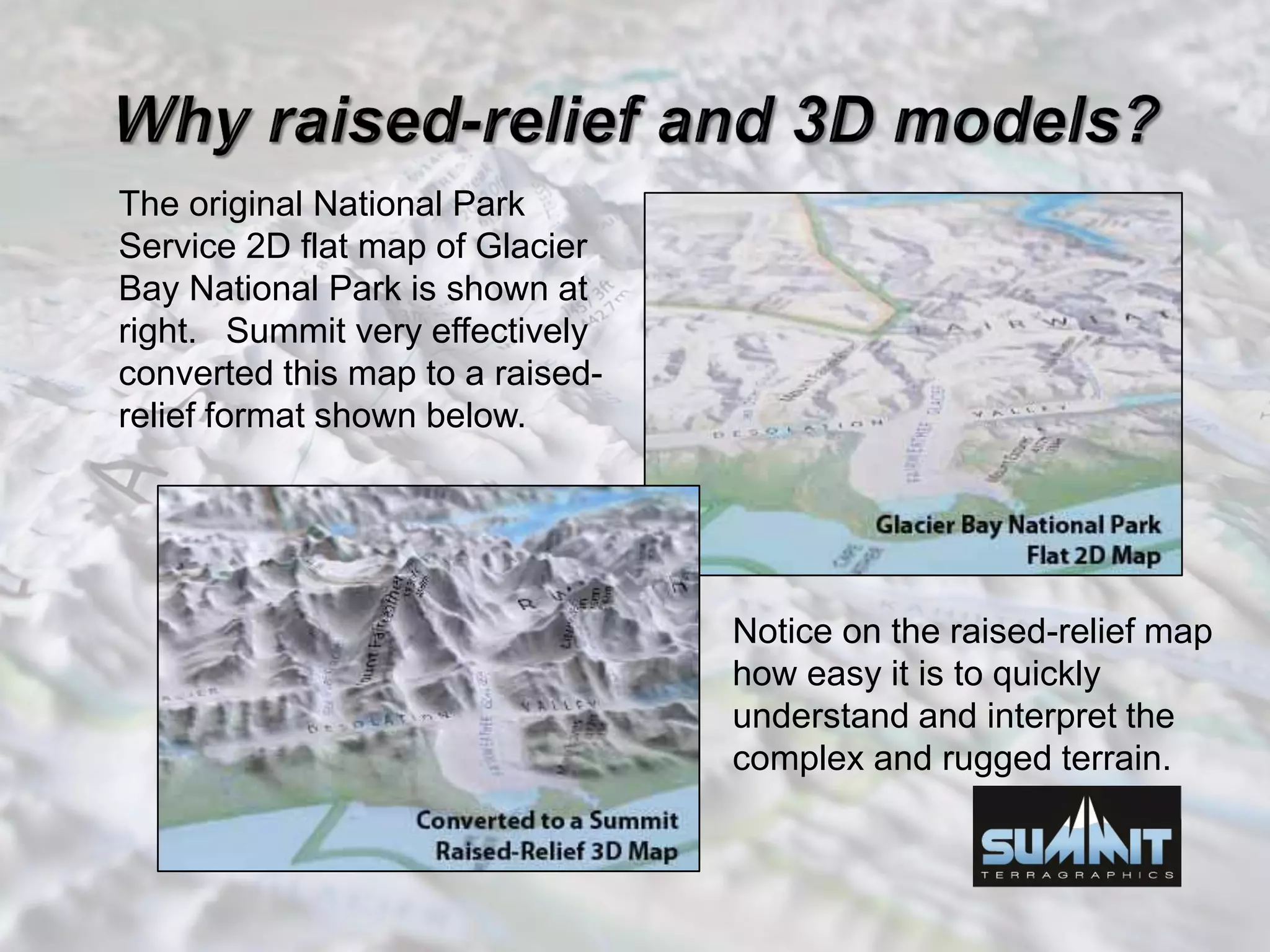

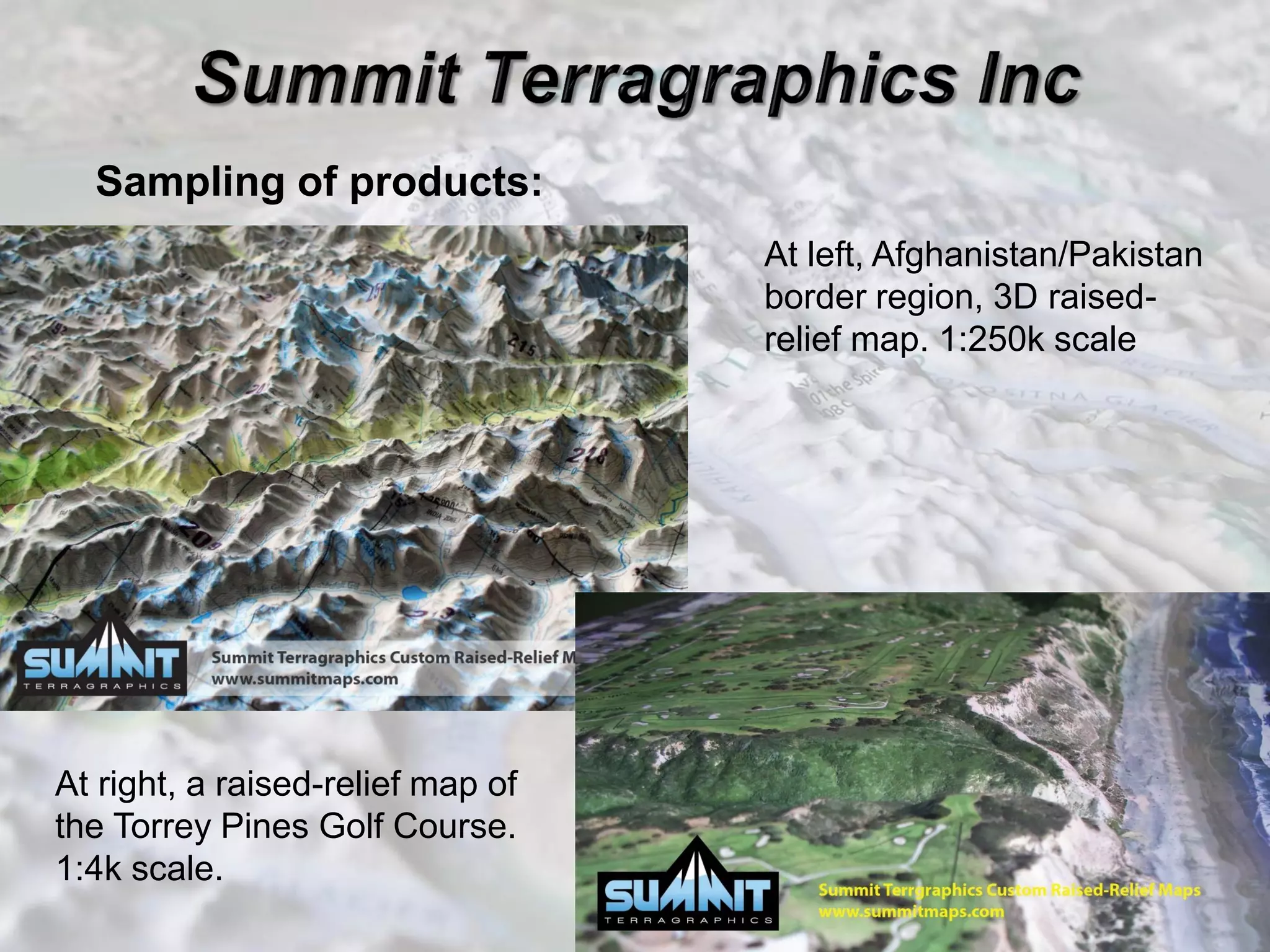

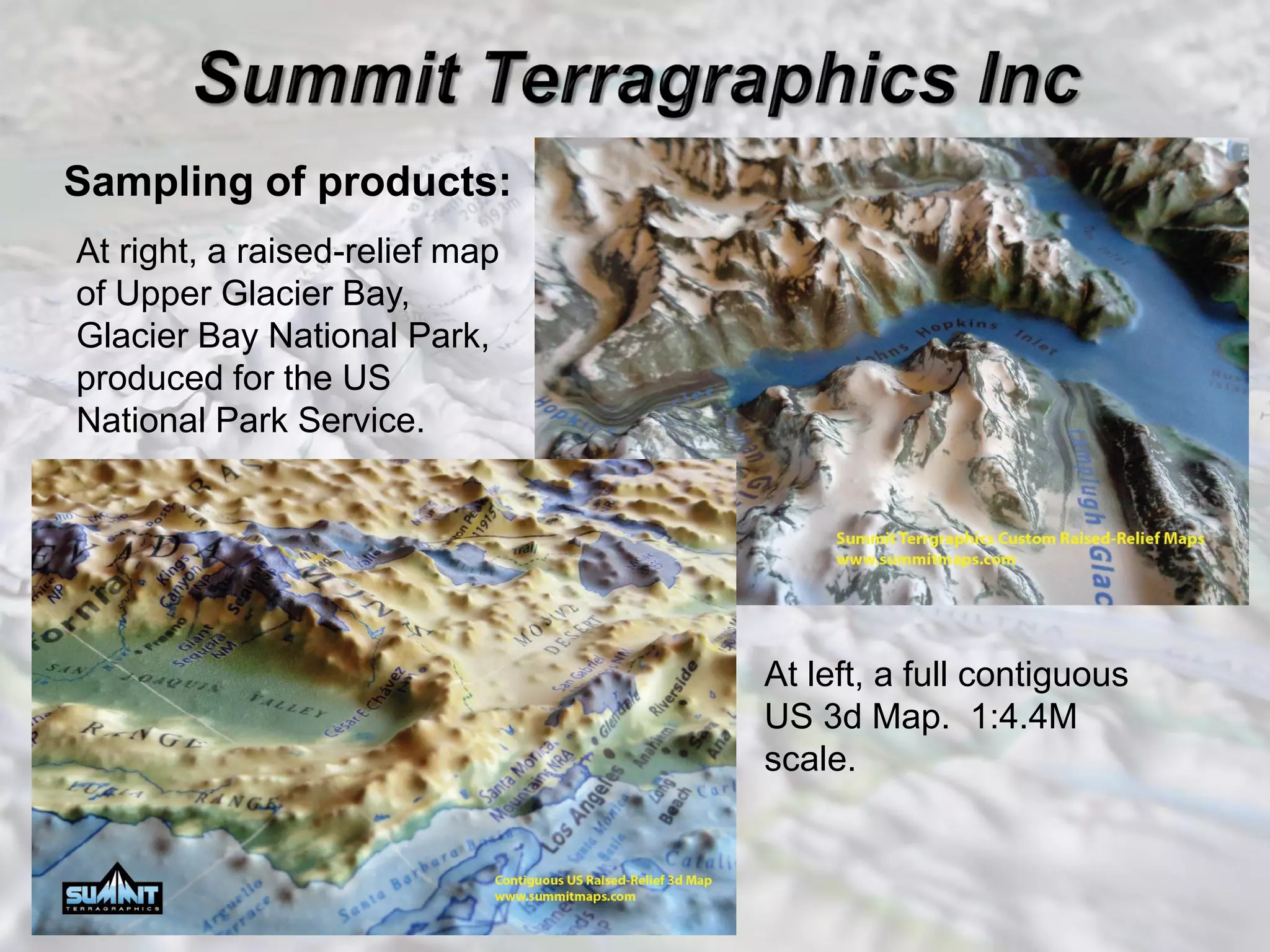

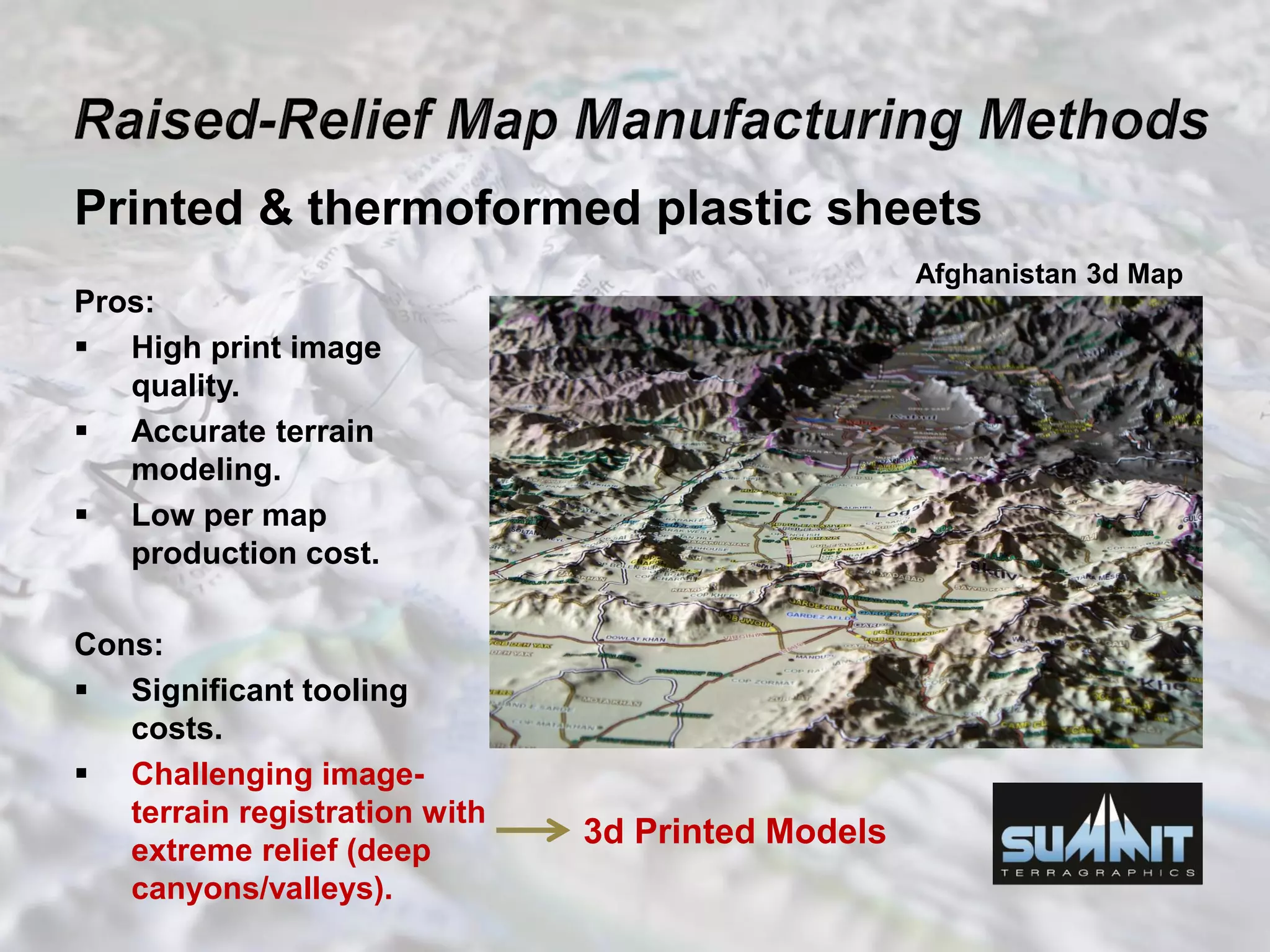

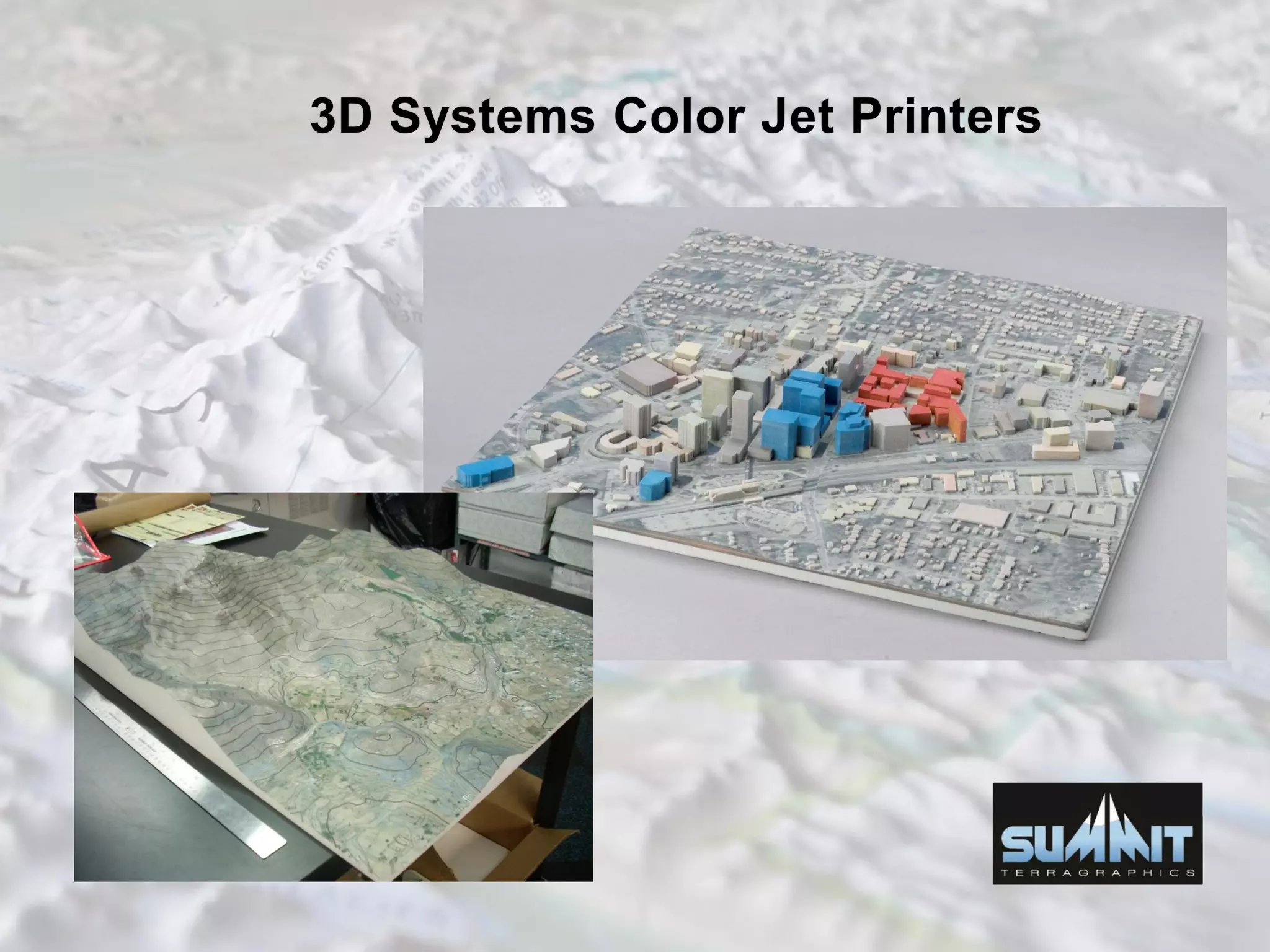

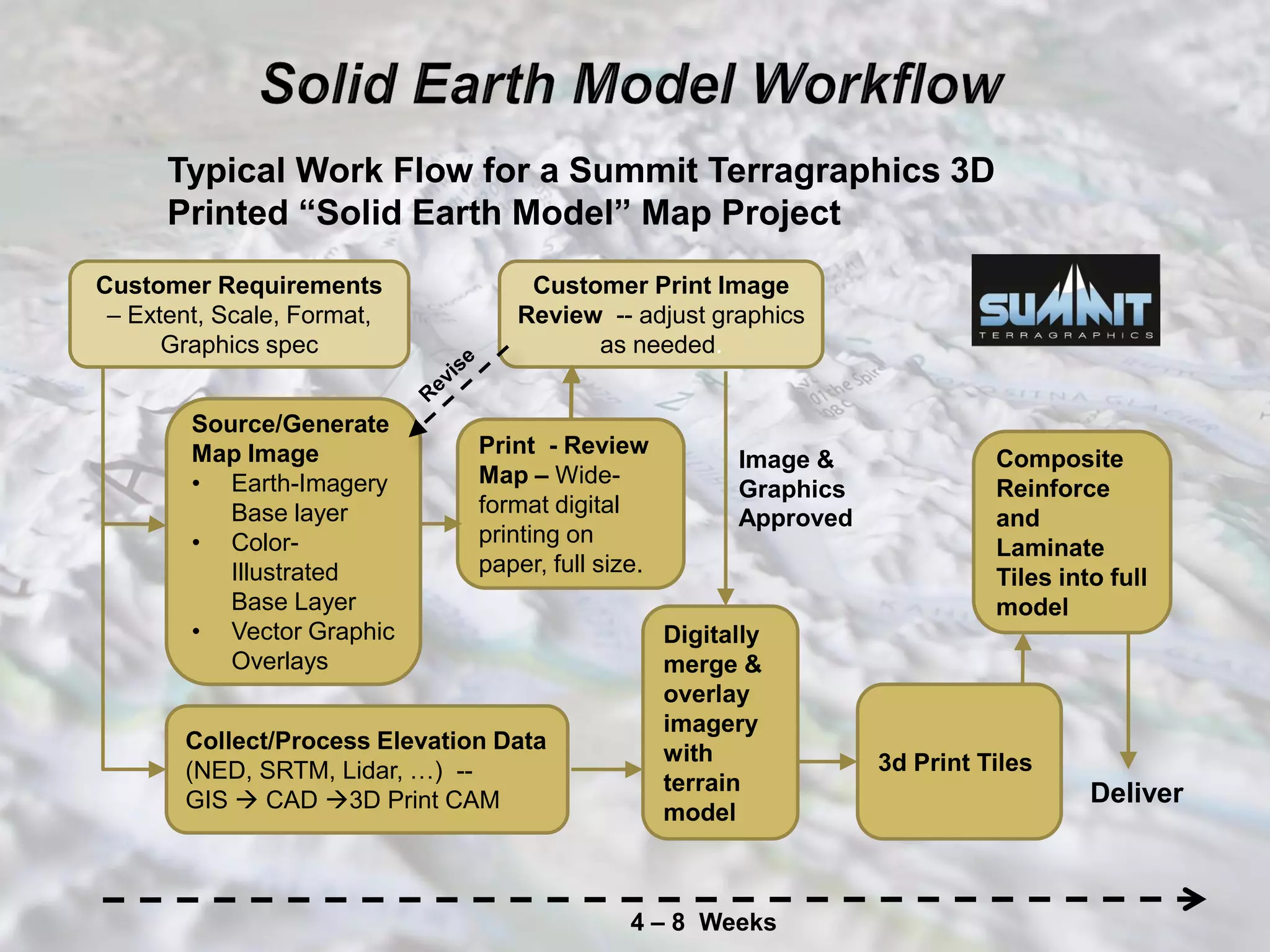

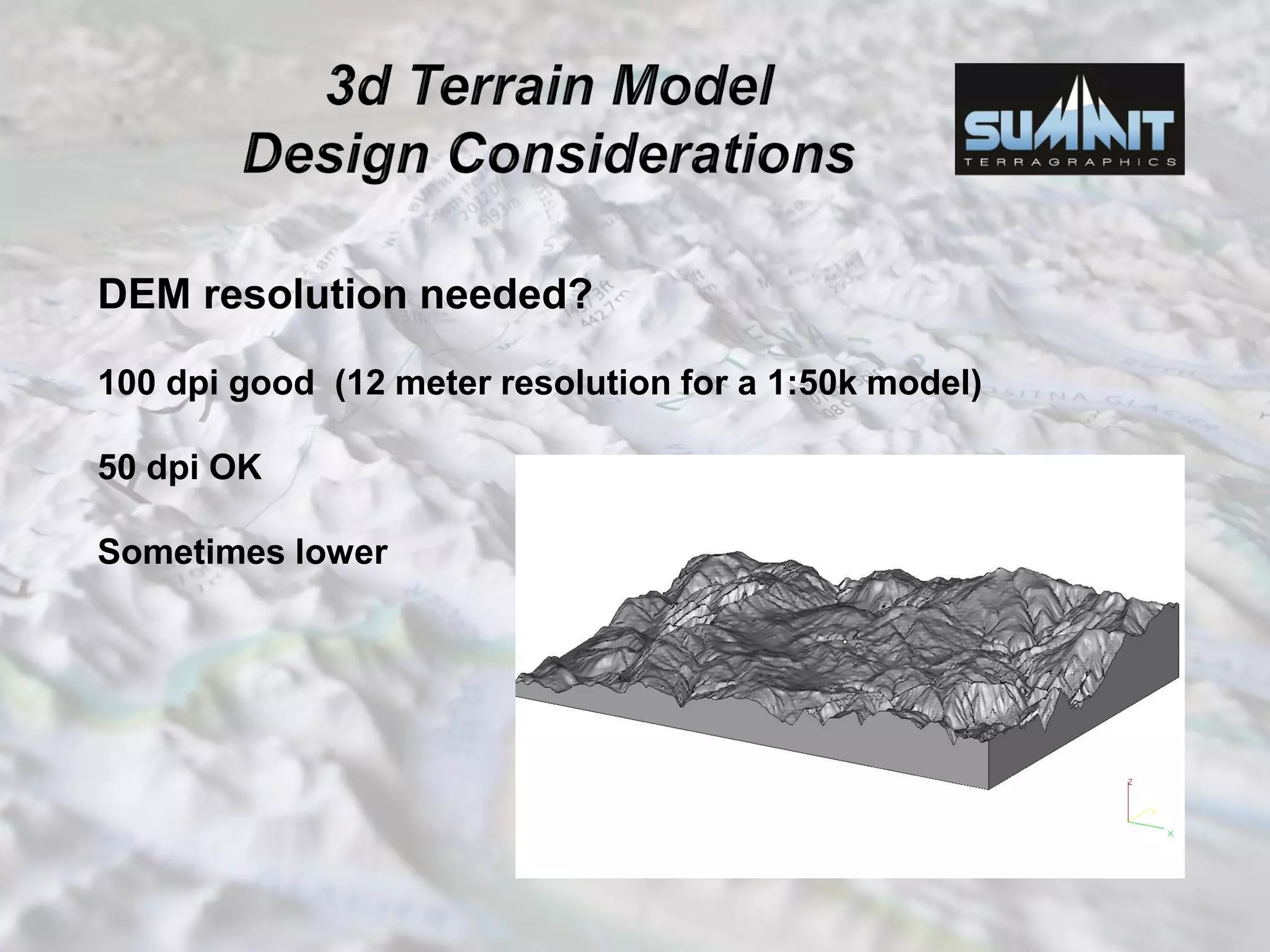

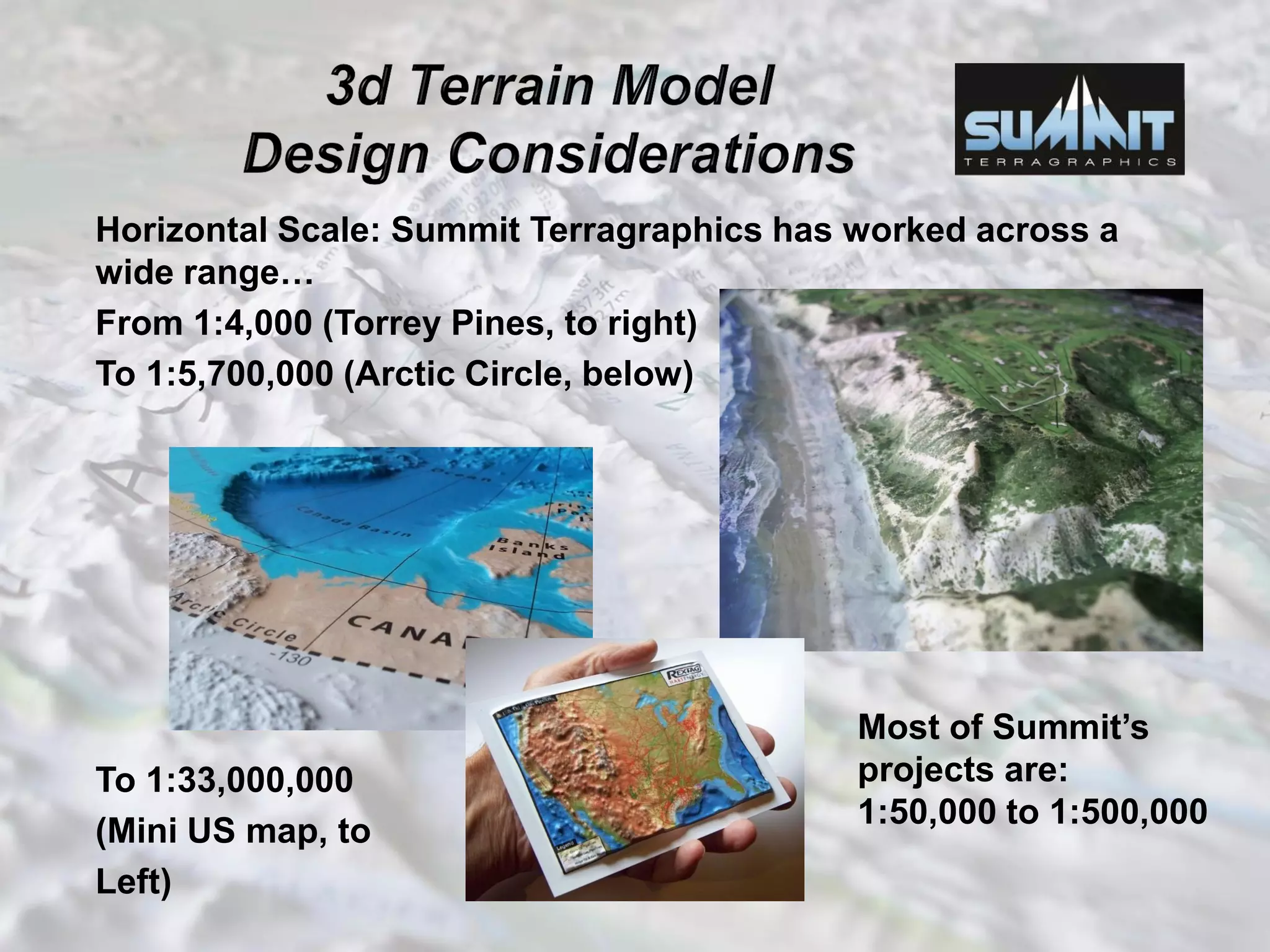

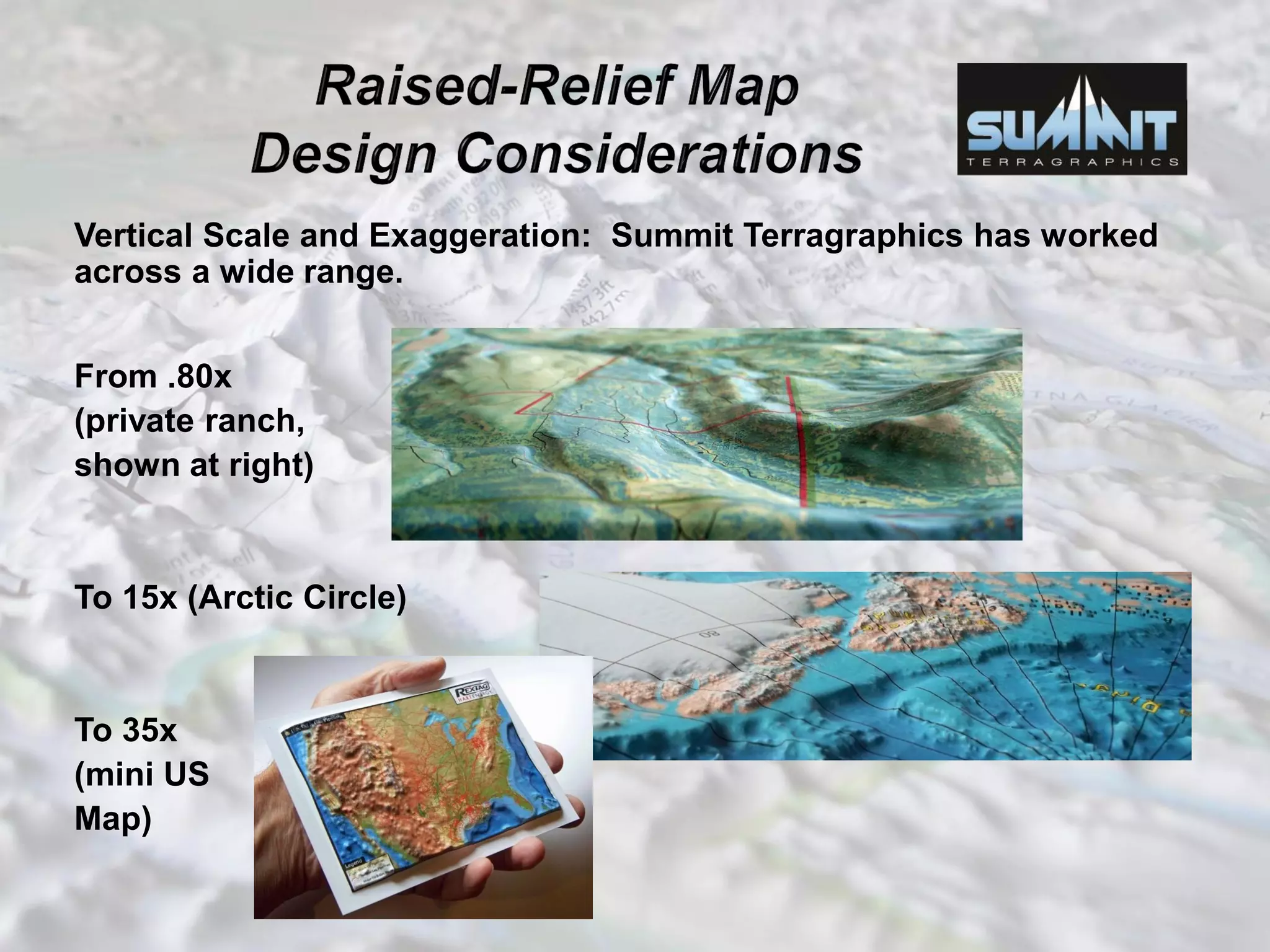

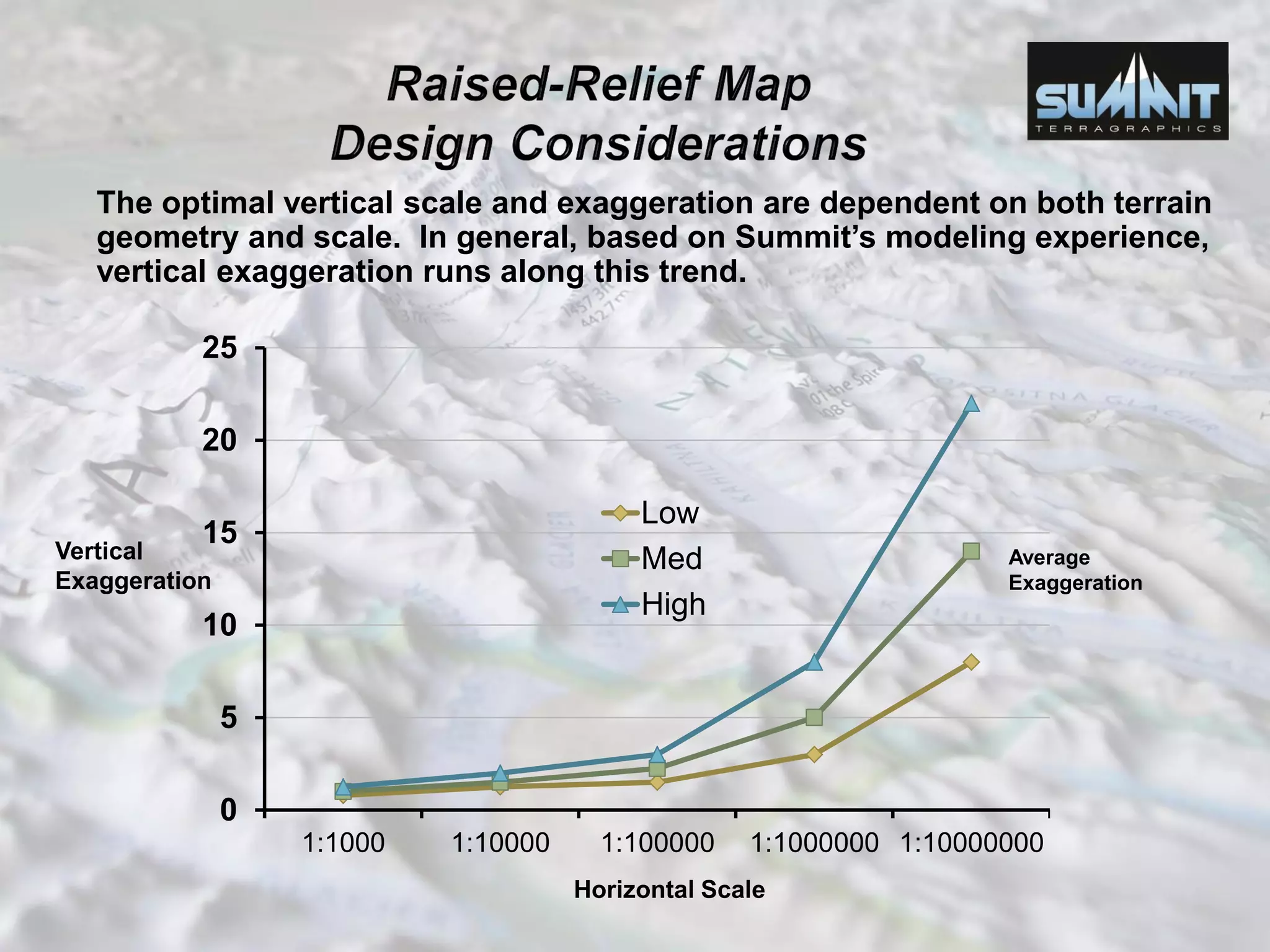

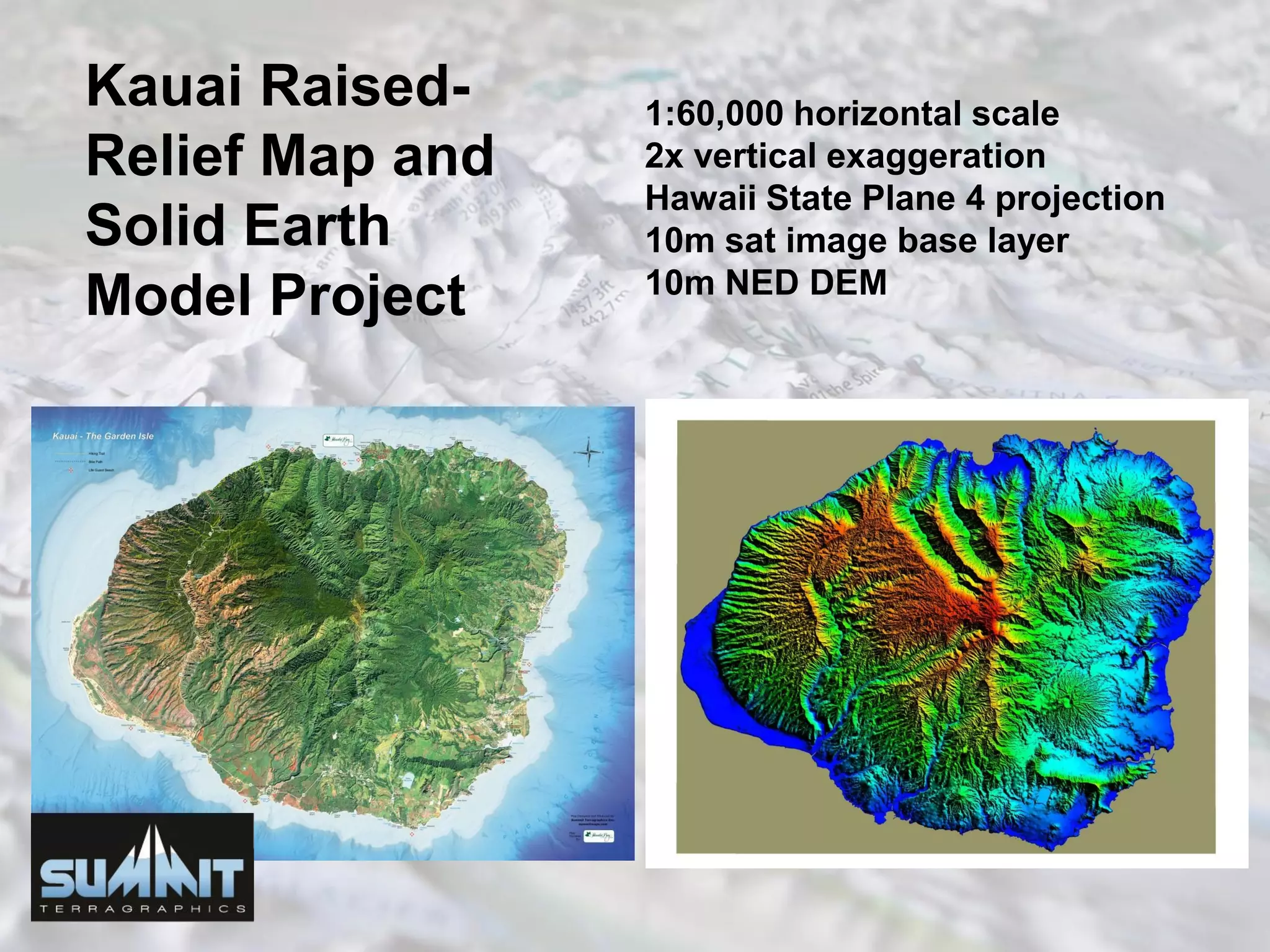

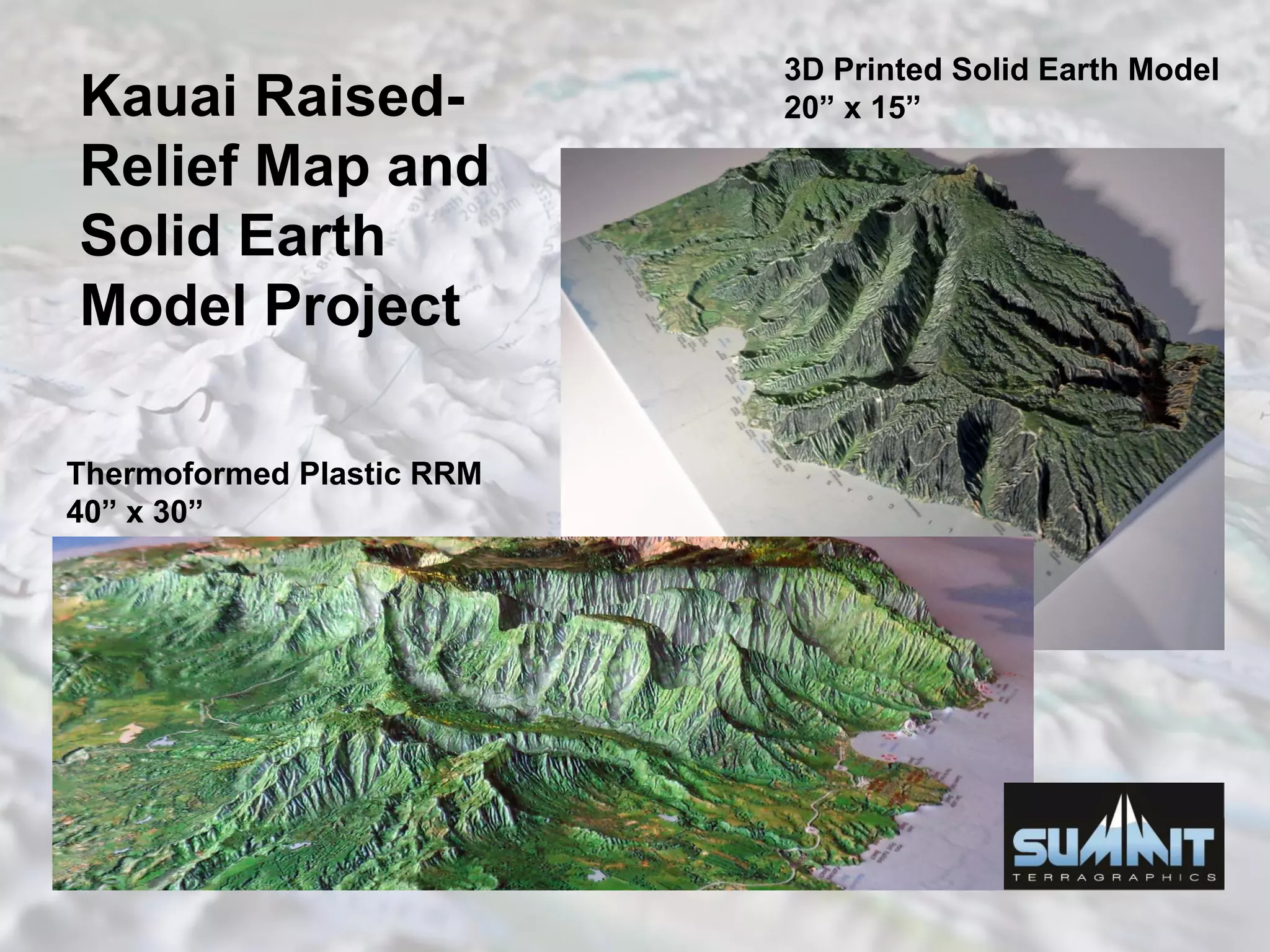

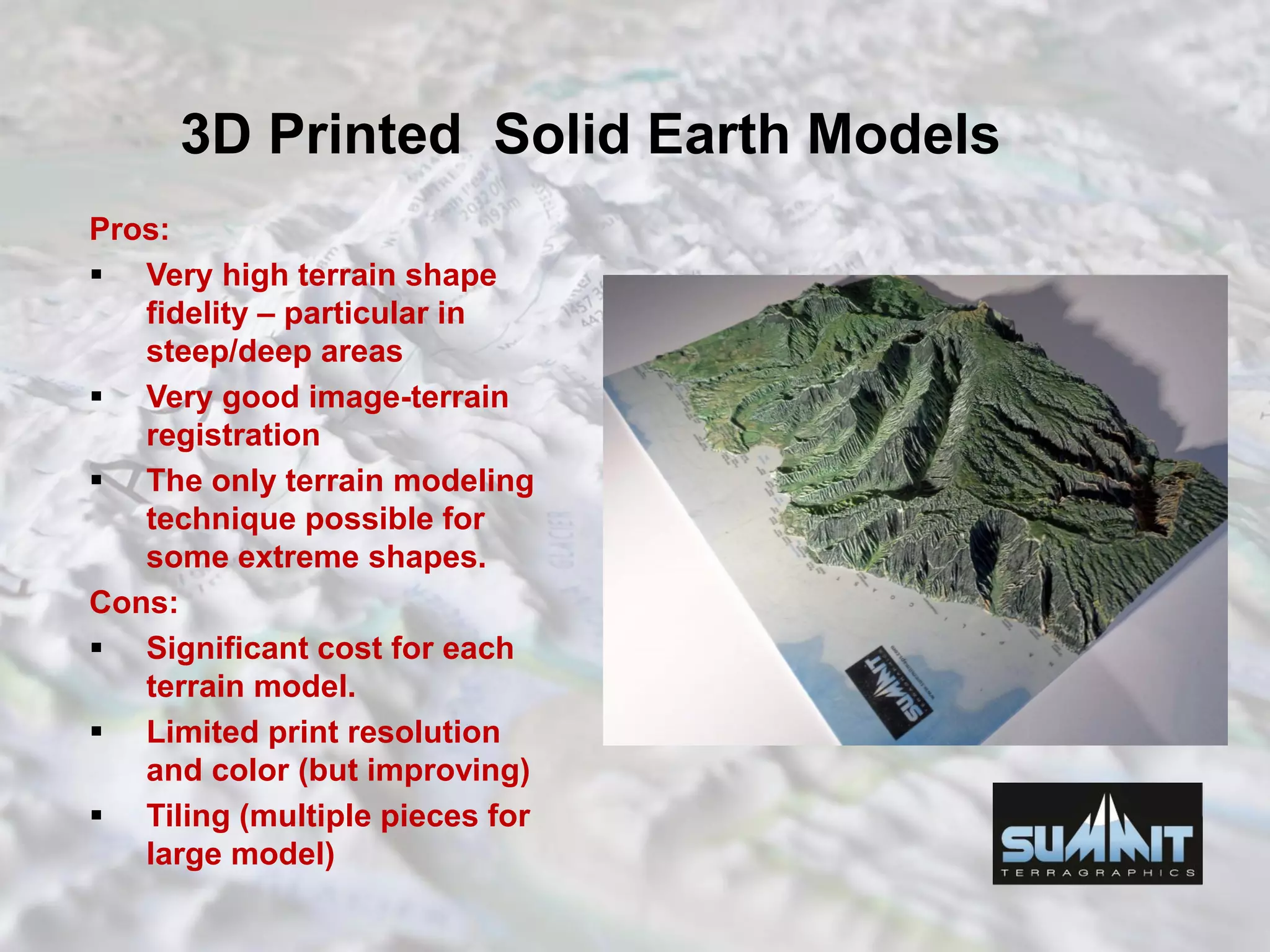

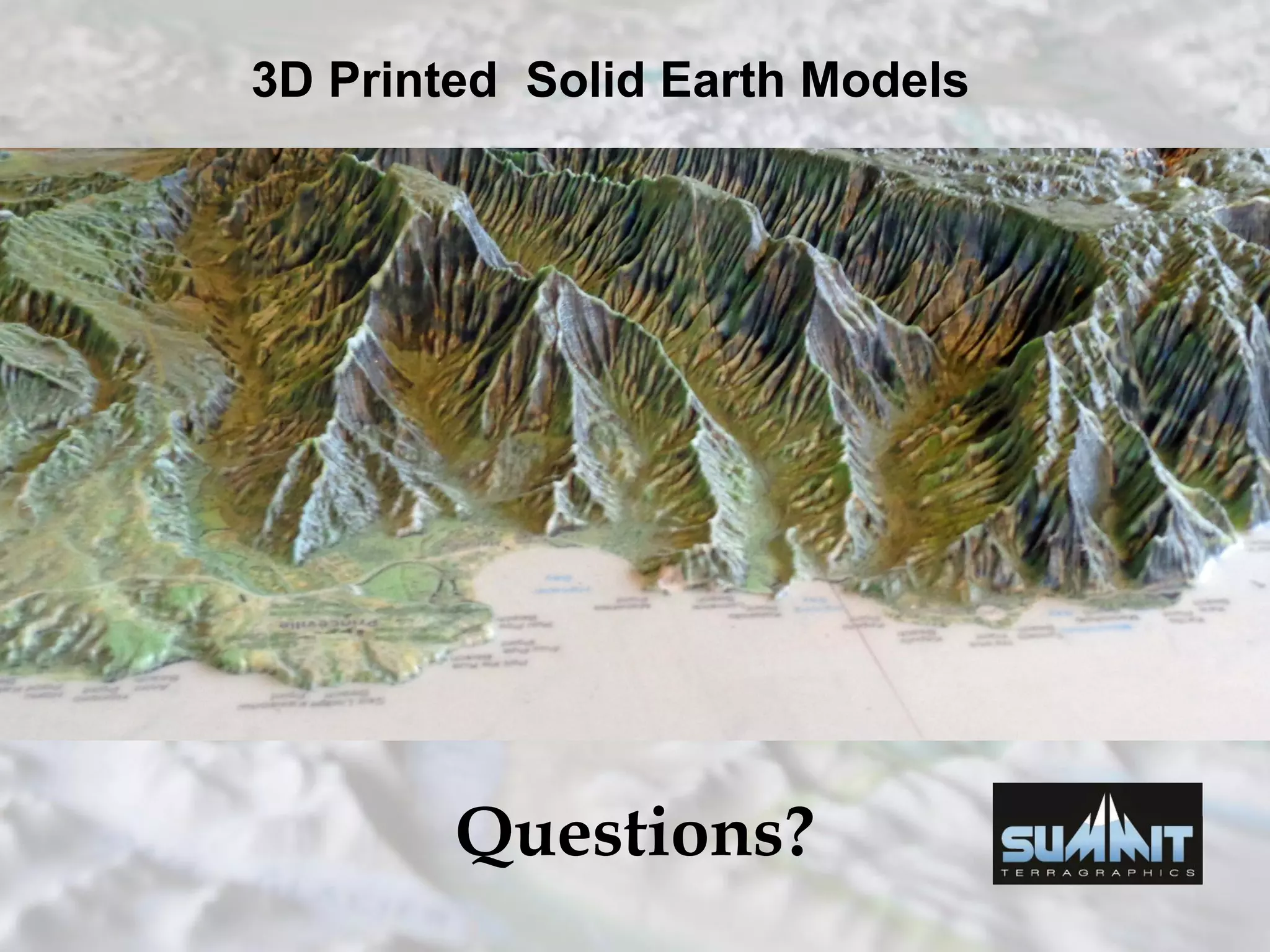

Summit Terragraphics is a leading provider of thermoformed raised-relief maps for various applications, utilizing 3D printing technology to create high-resolution and accurate terrain models. The document discusses the benefits and challenges of 3D maps, emphasizing their effectiveness in interpreting complex terrains compared to traditional flat maps. Additionally, it outlines the workflow involved in producing these models, from client specifications to final delivery.