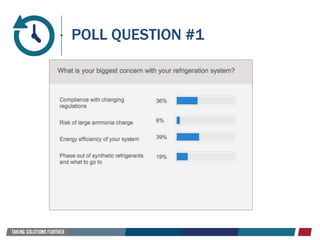

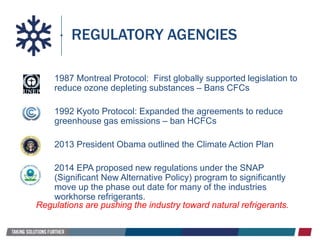

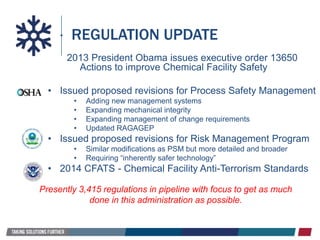

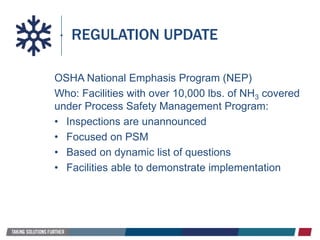

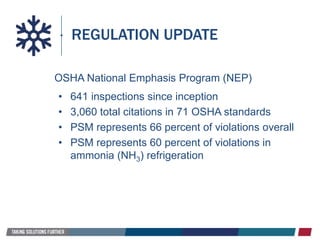

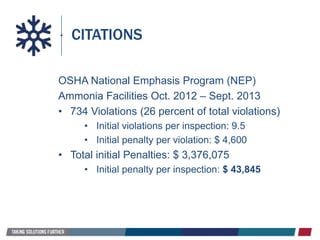

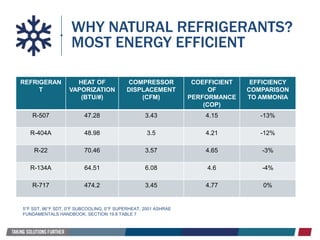

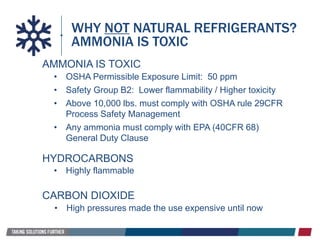

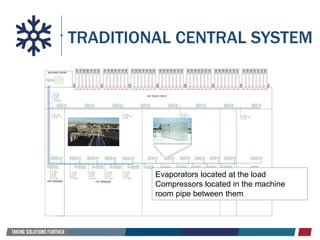

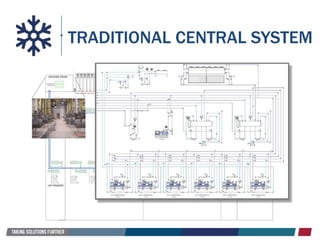

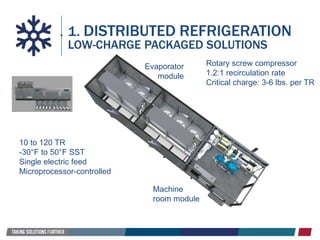

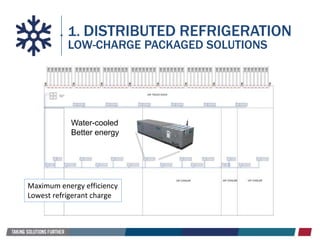

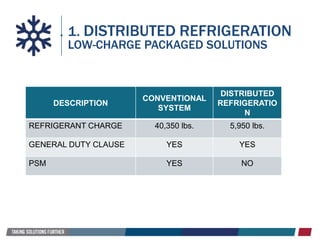

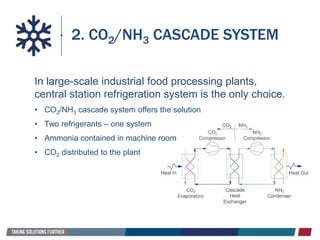

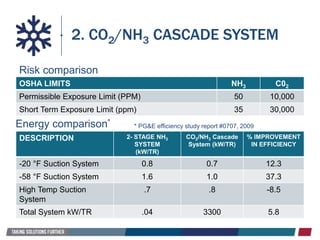

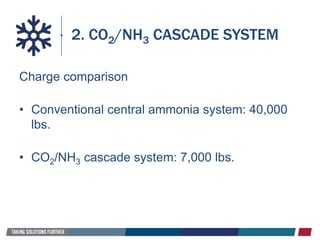

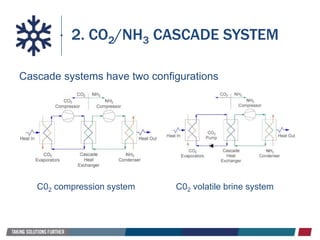

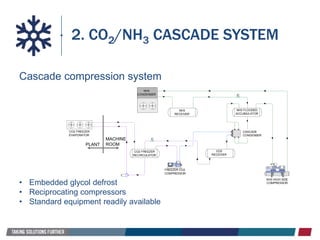

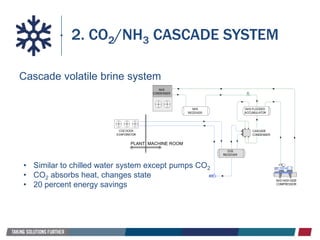

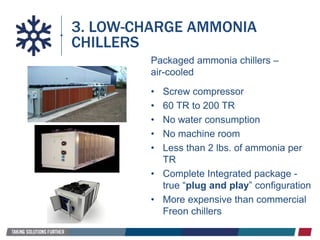

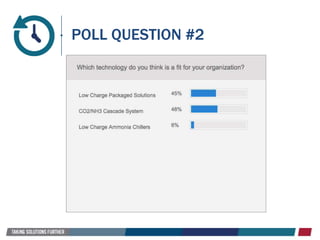

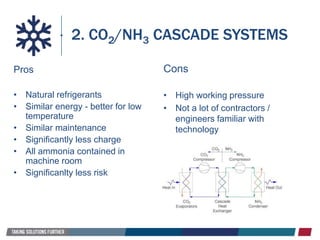

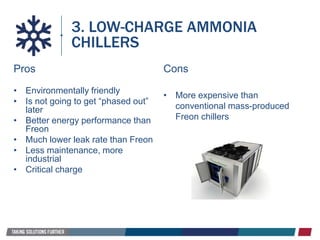

The document discusses the evolving landscape of refrigeration technologies in response to climate change and regulatory compliance, emphasizing natural refrigerants such as ammonia and carbon dioxide. It outlines the implications of updated regulations, potential innovations like low-charge ammonia chillers and CO2/NH3 cascade systems, and the increasing push for environmentally friendly solutions. Key takeaways include the transition away from synthetic refrigerants, the importance of compliance with safety regulations, and the advantages of adopting distributed refrigeration systems to reduce risks associated with large ammonia charges.