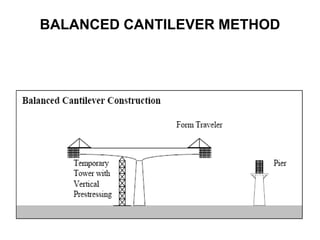

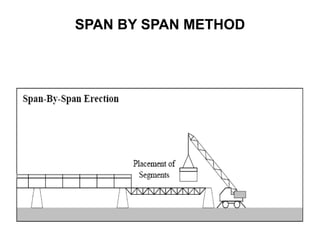

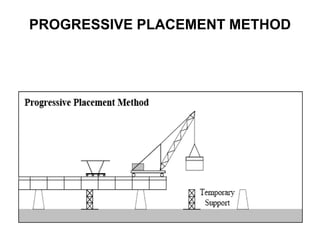

There are three main bridge construction launching techniques: balanced cantilever, span by span, and progressive placement. The balanced cantilever method involves building outward from both sides of each pier simultaneously. The span by span method assembles all segments for a span together before lifting into place. The progressive placement method builds the bridge in one direction by placing segments at the tip of a advancing cantilever arm.