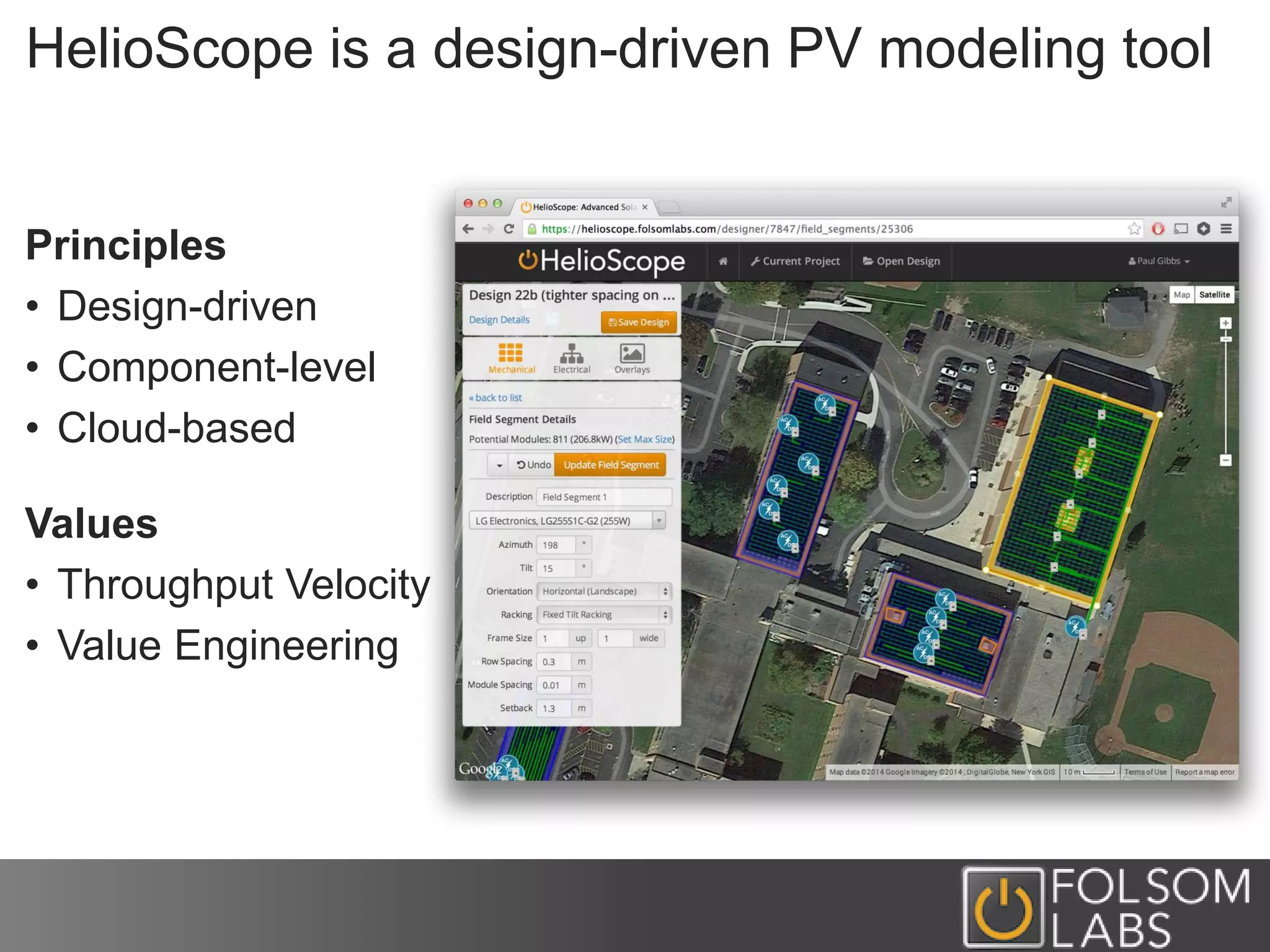

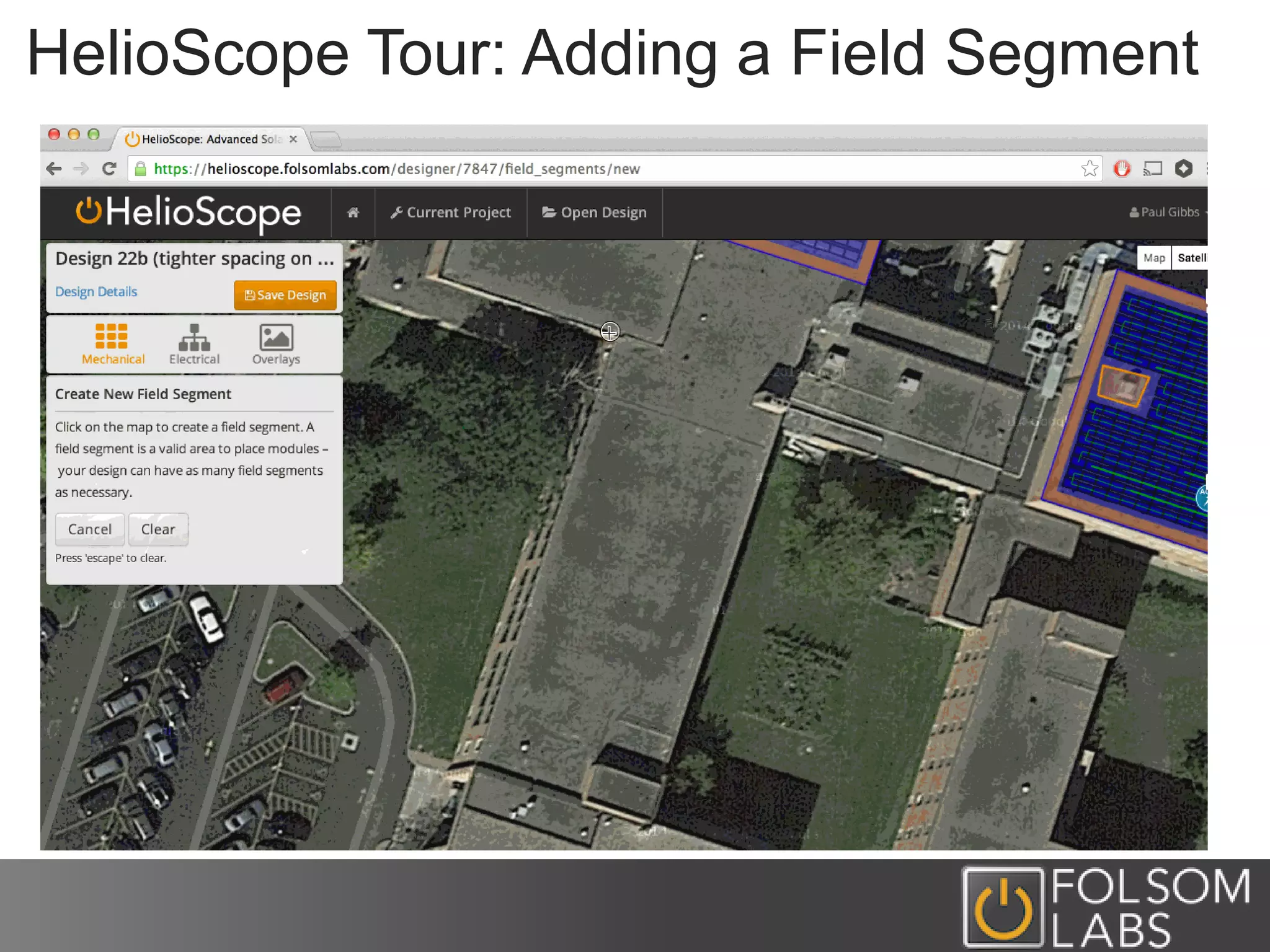

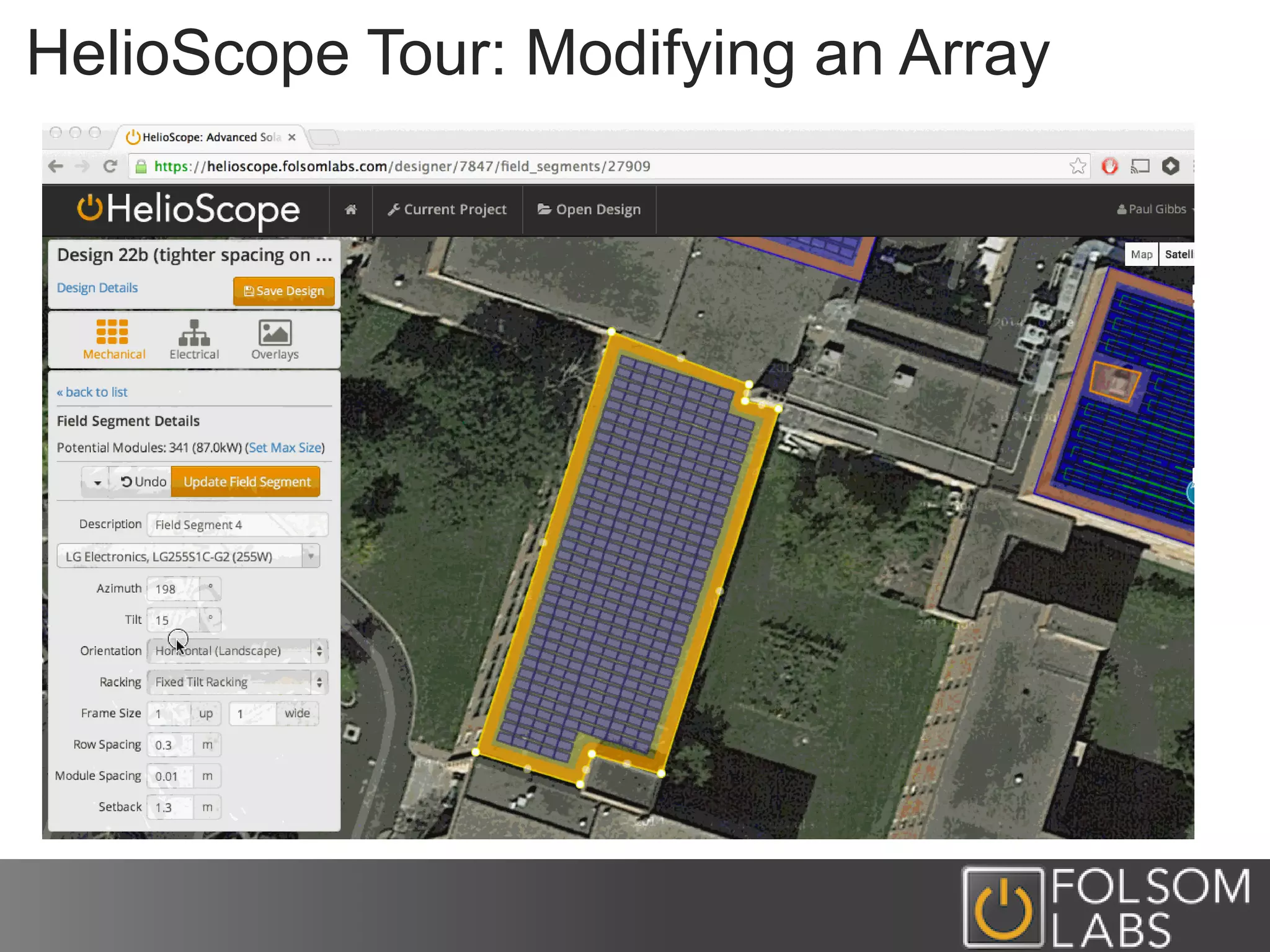

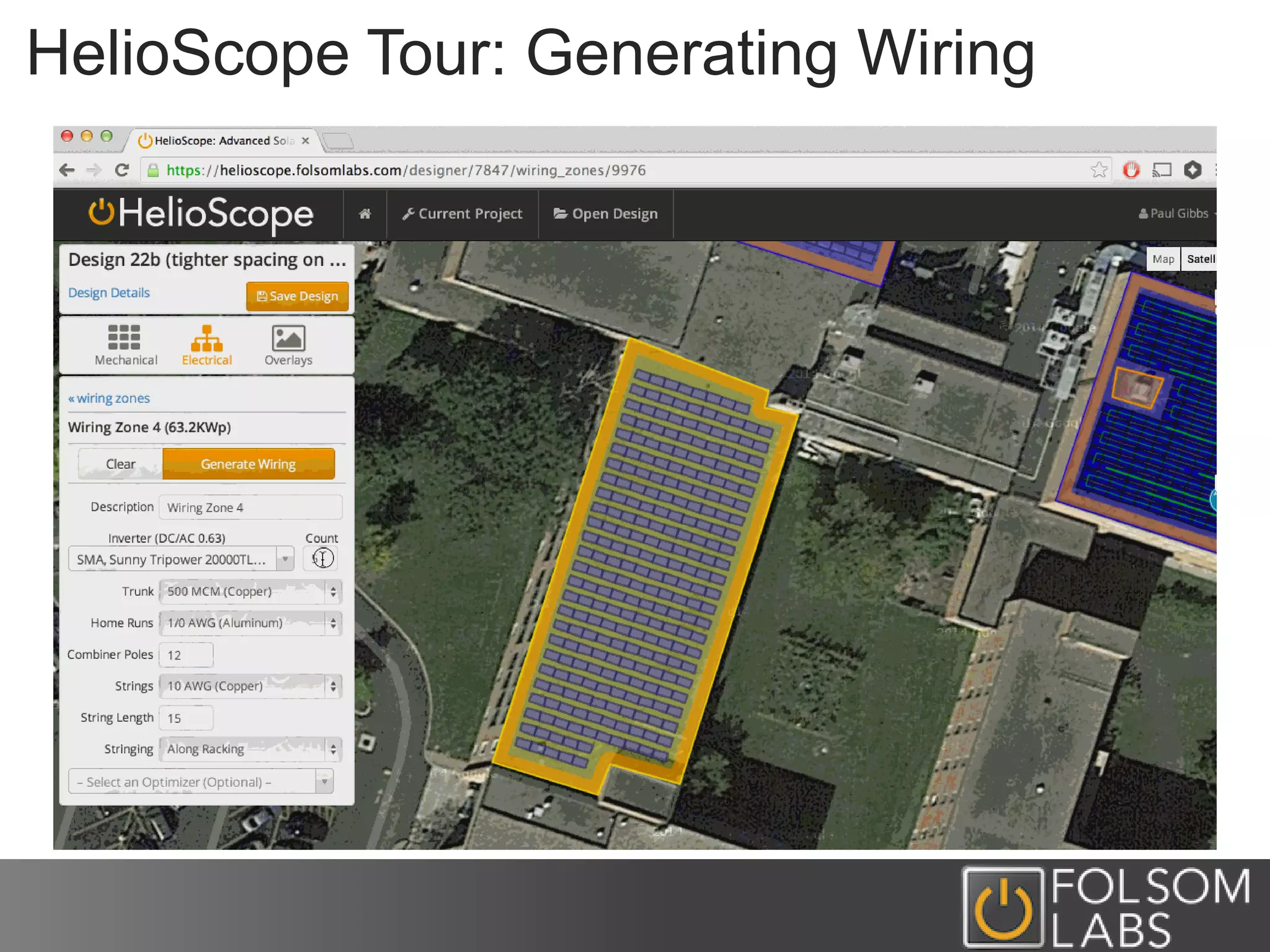

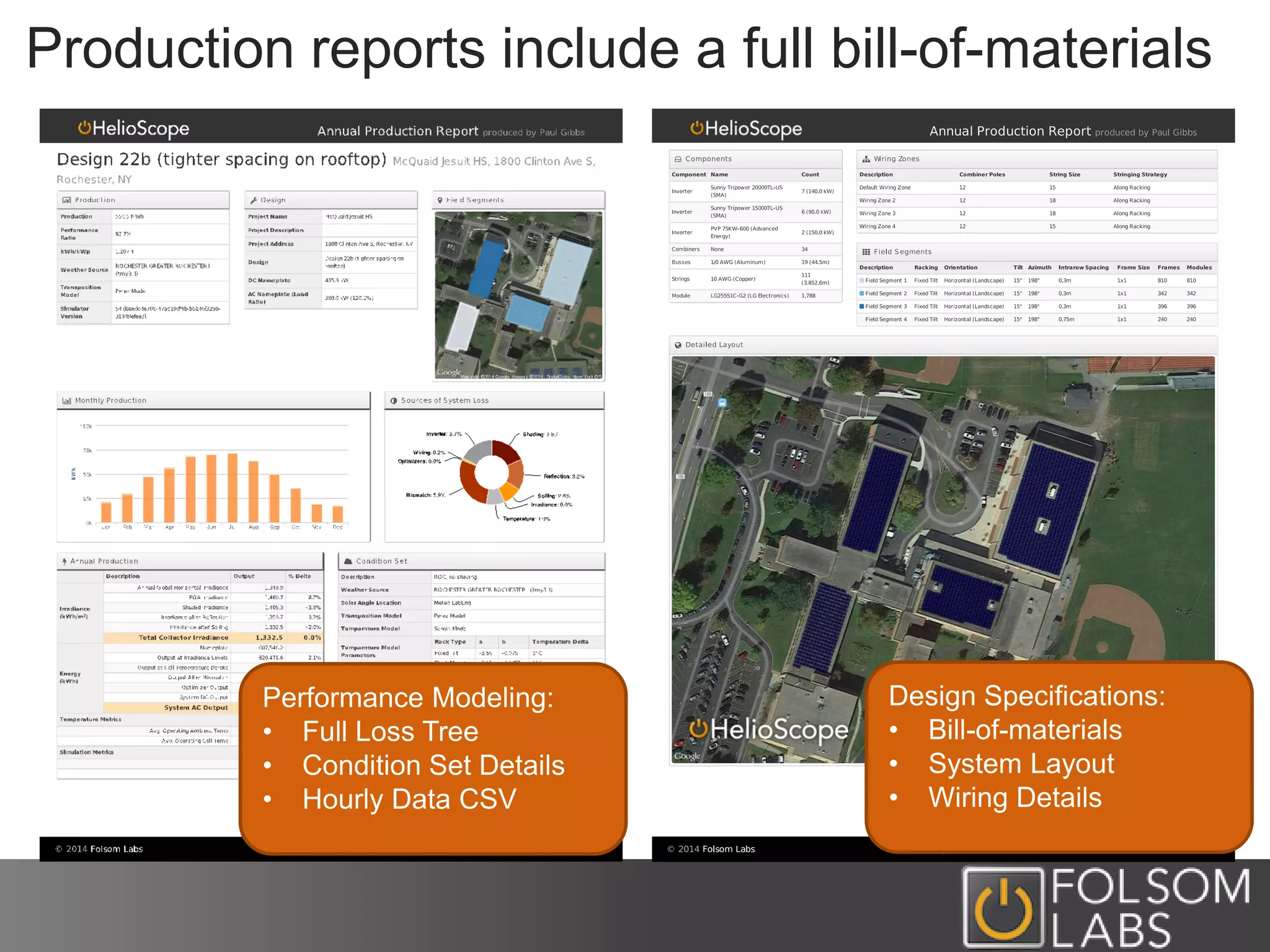

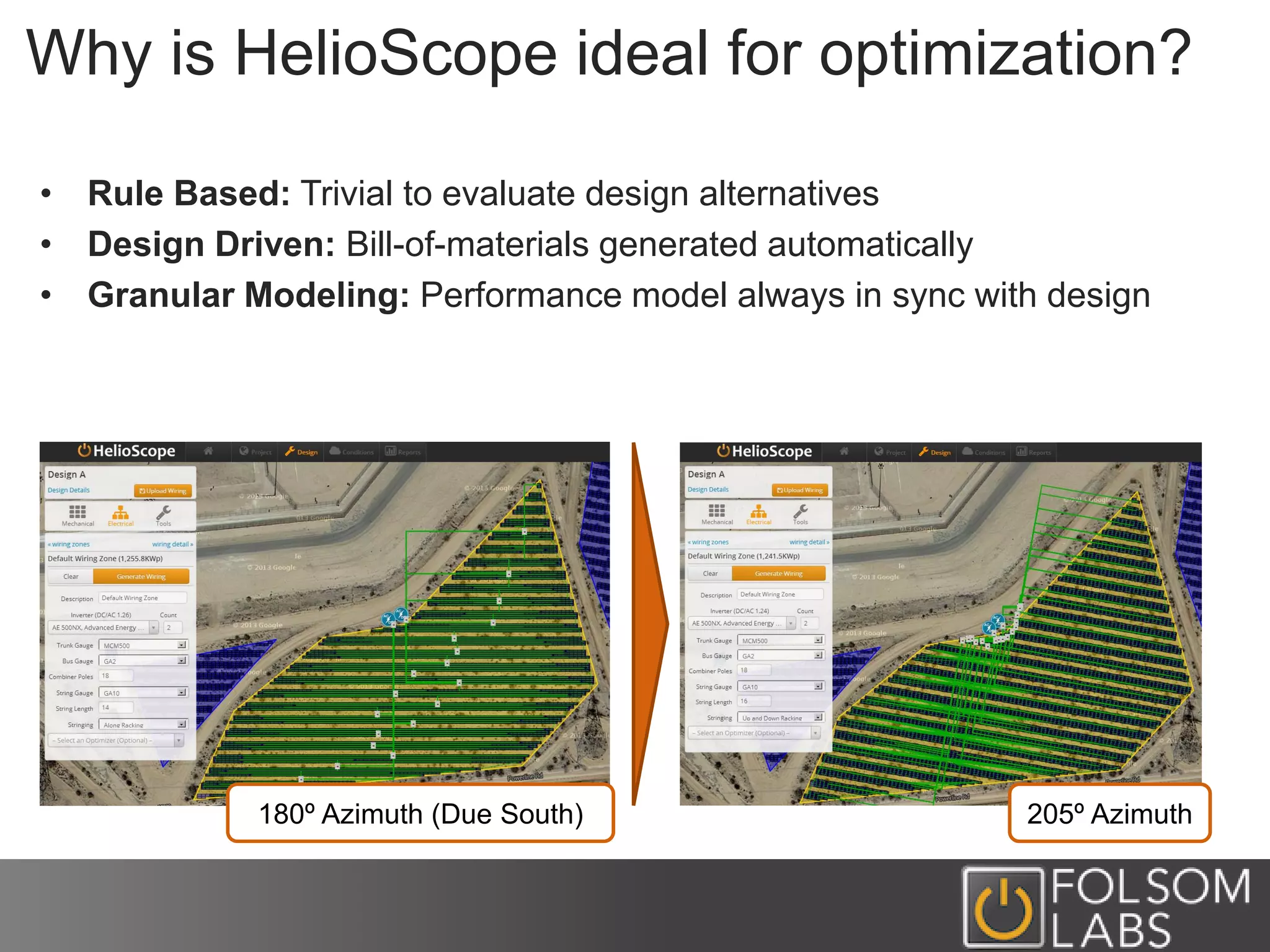

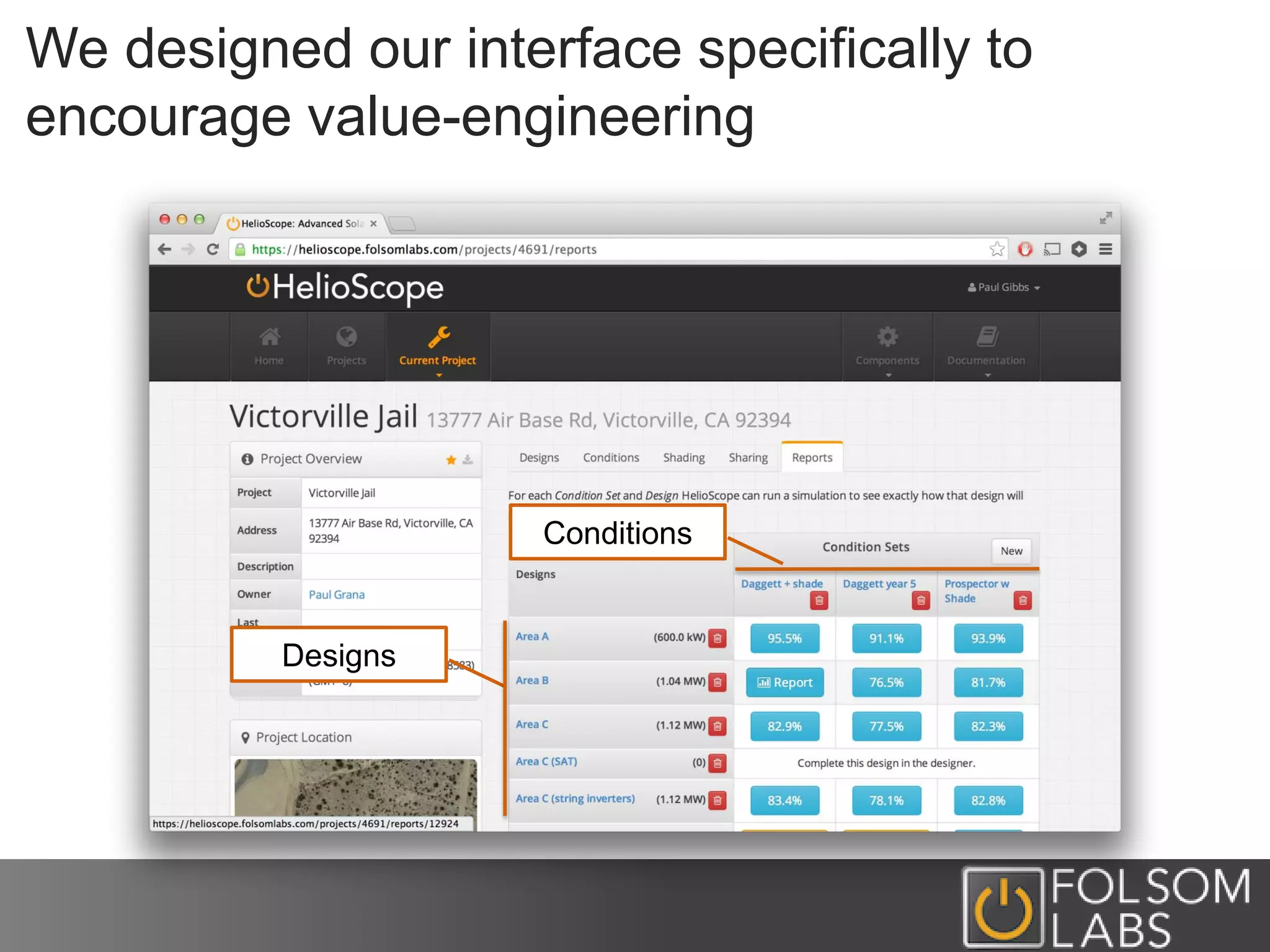

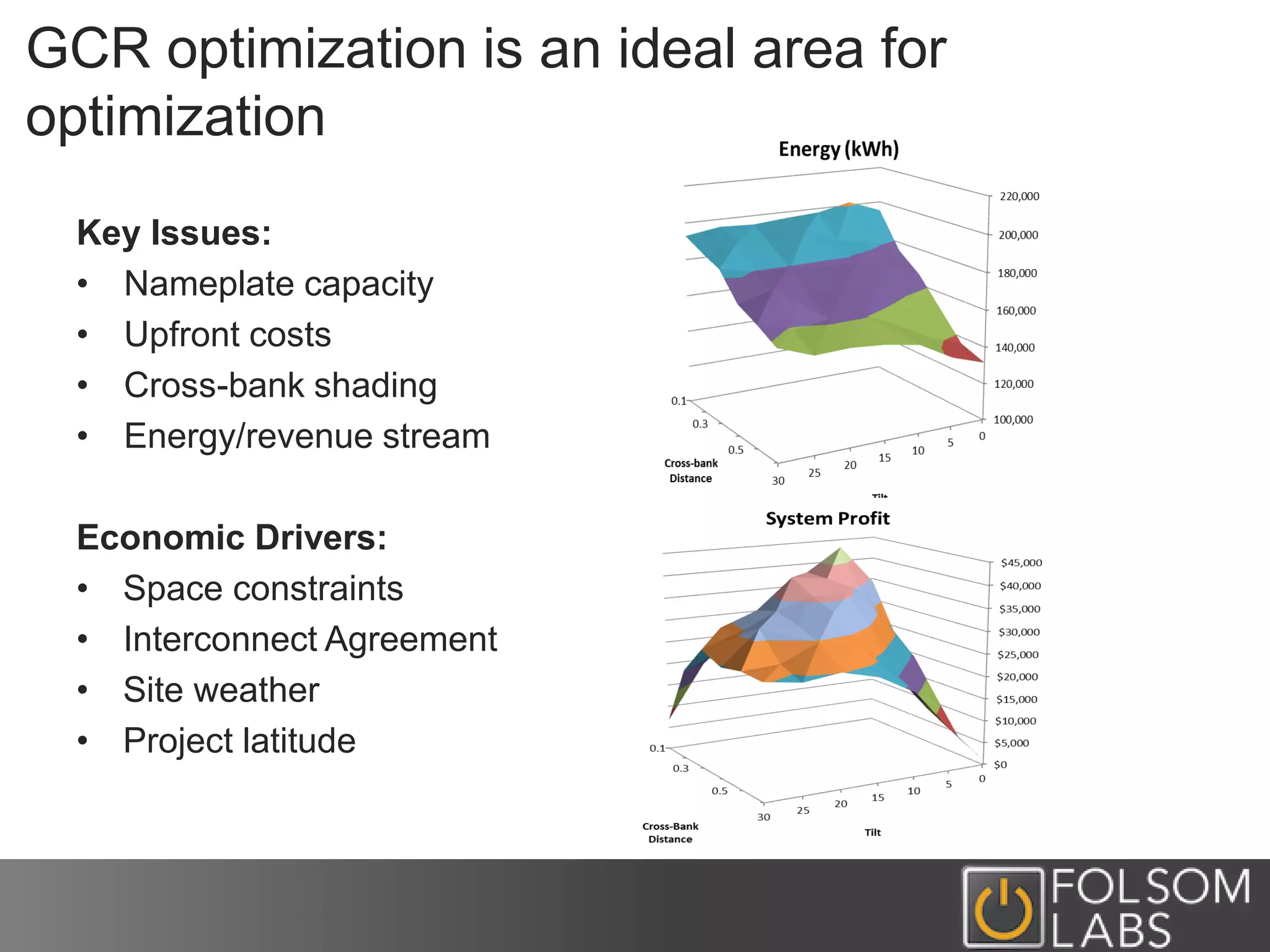

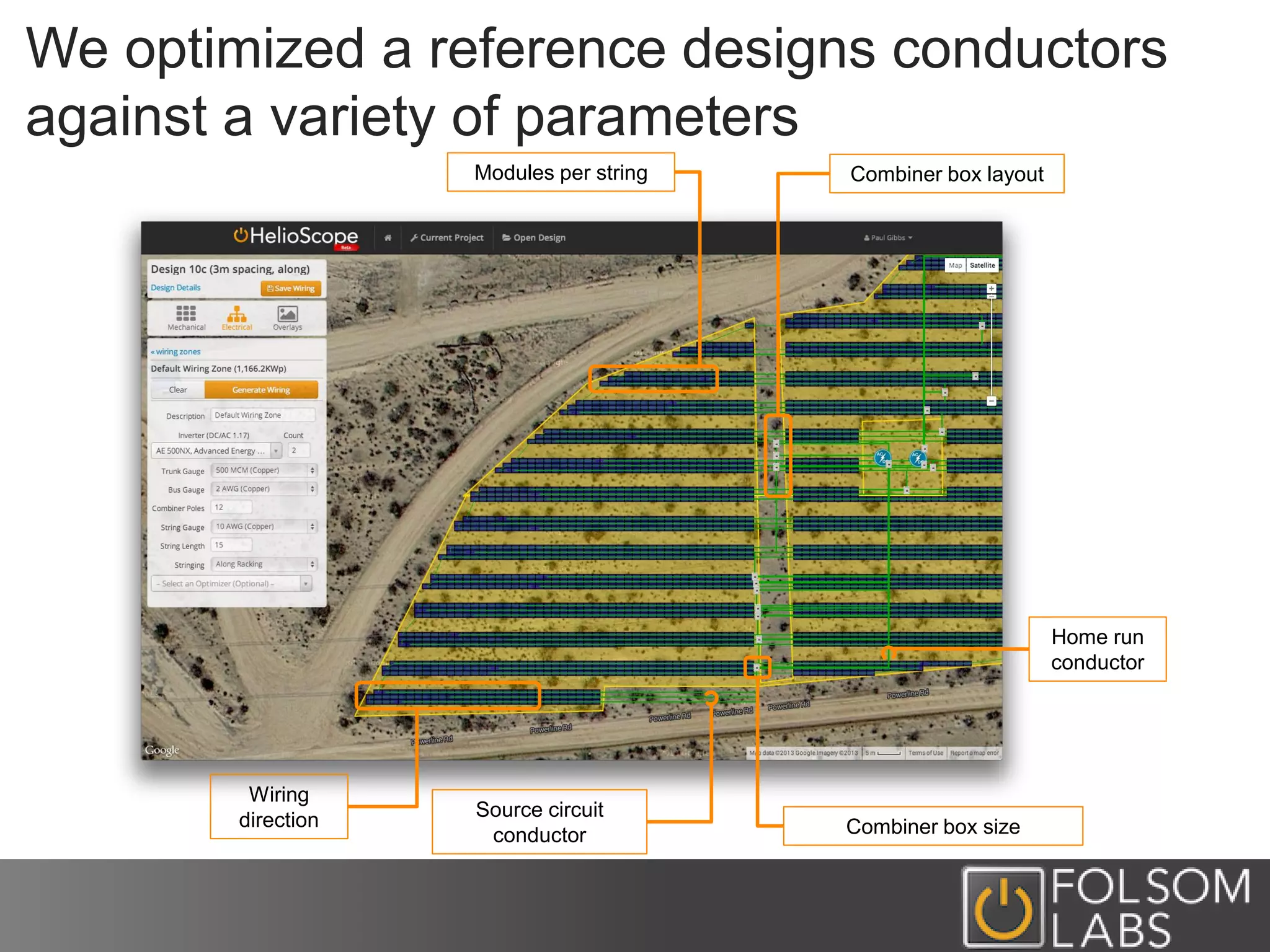

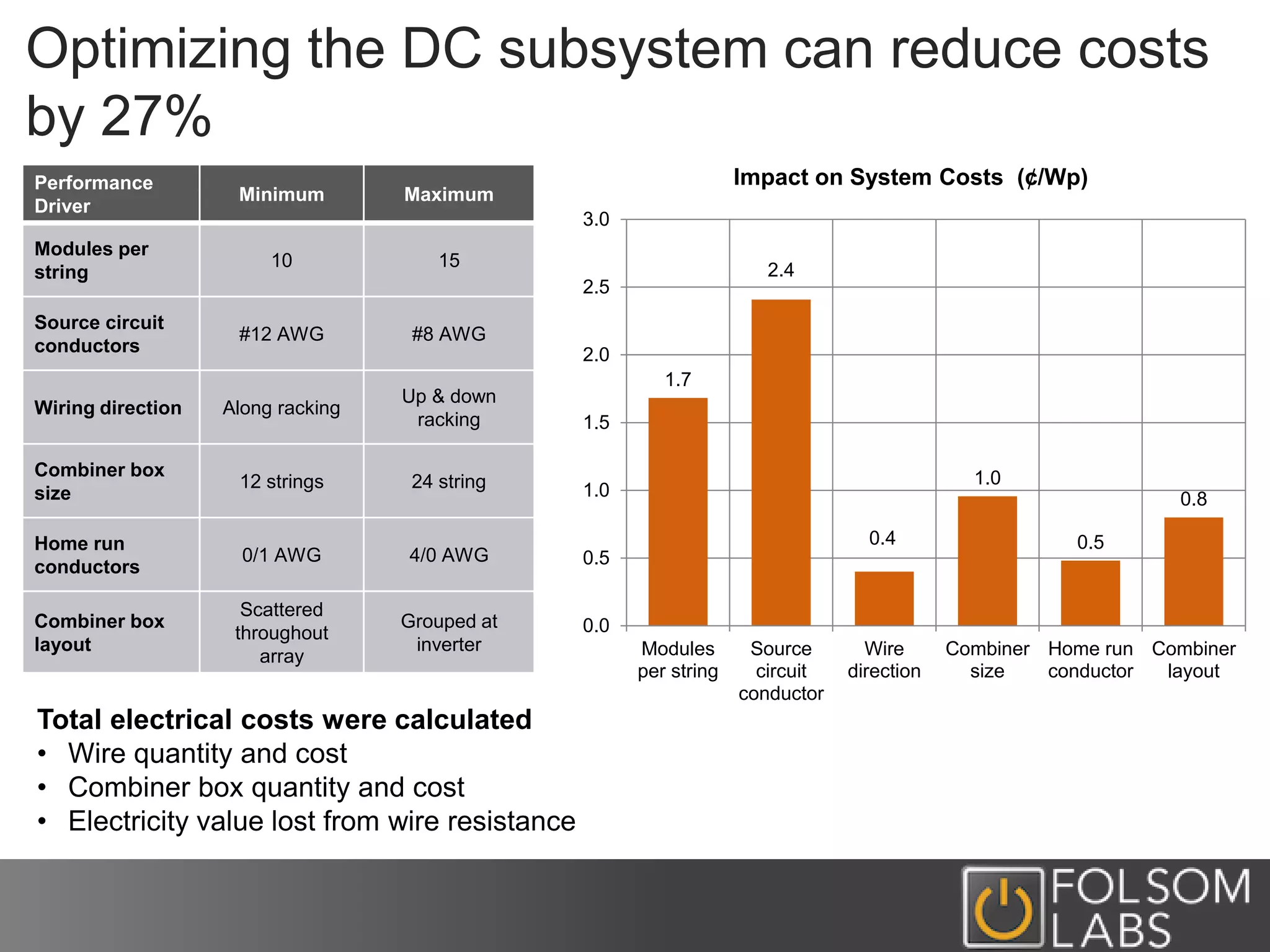

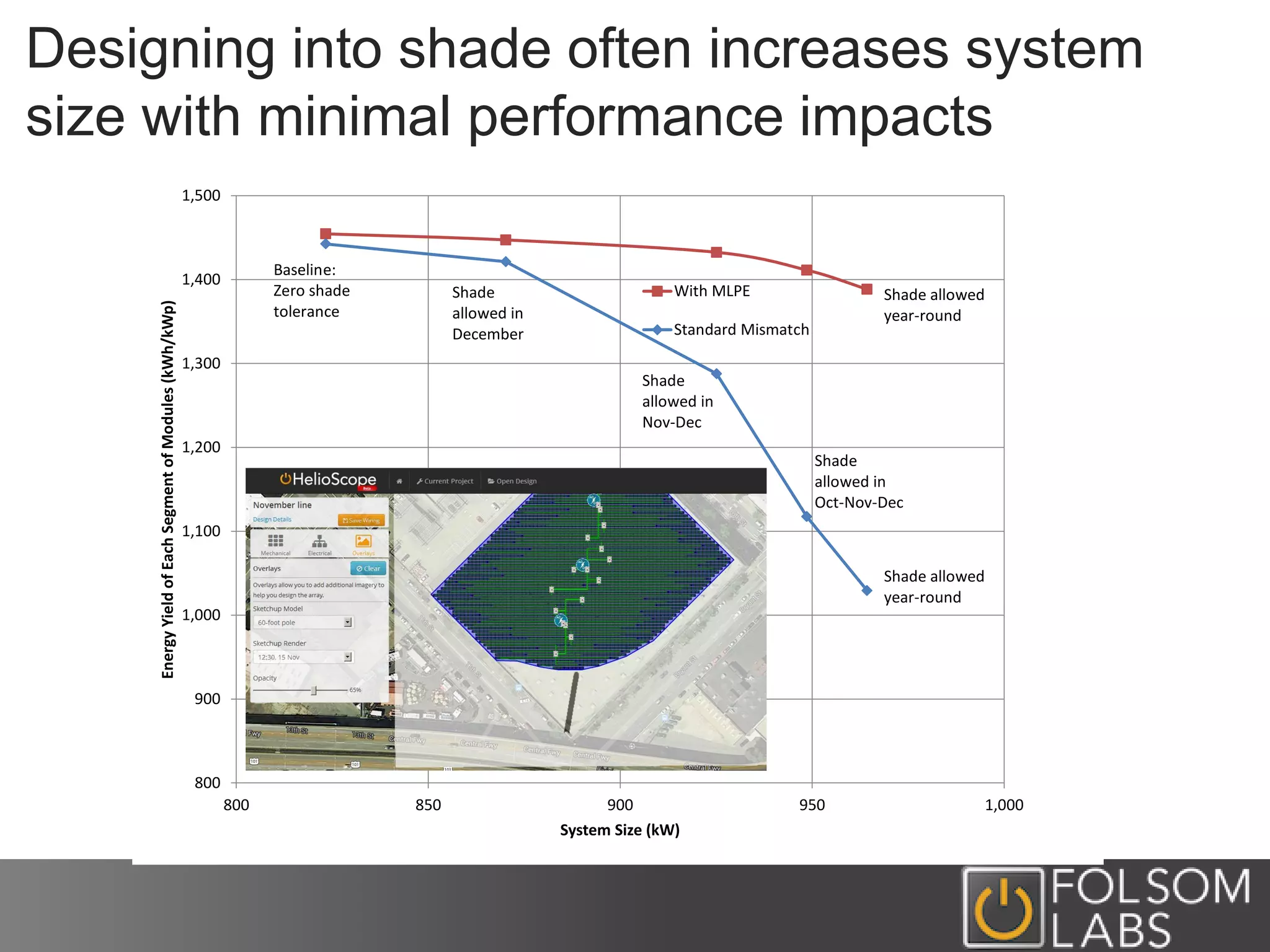

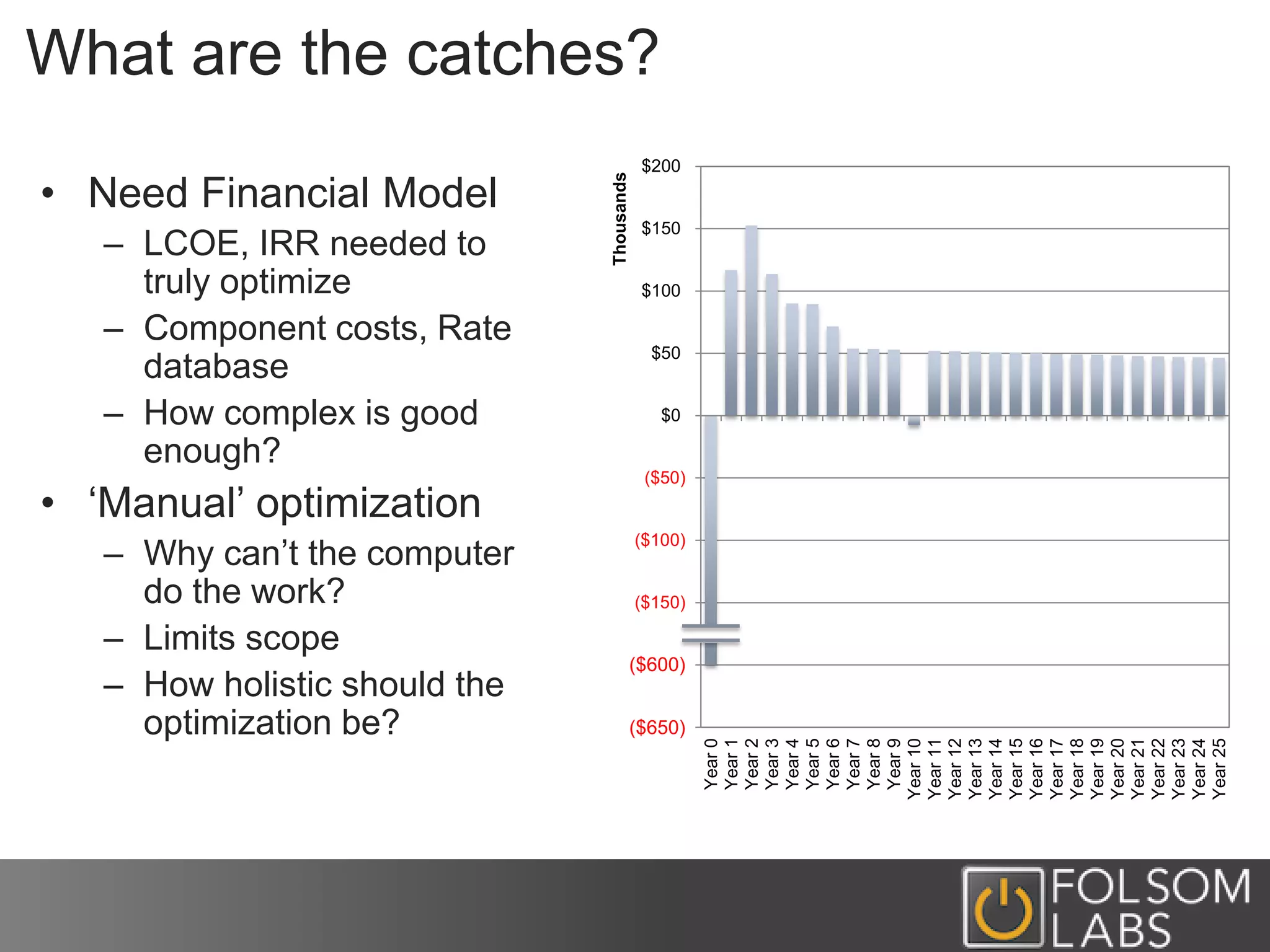

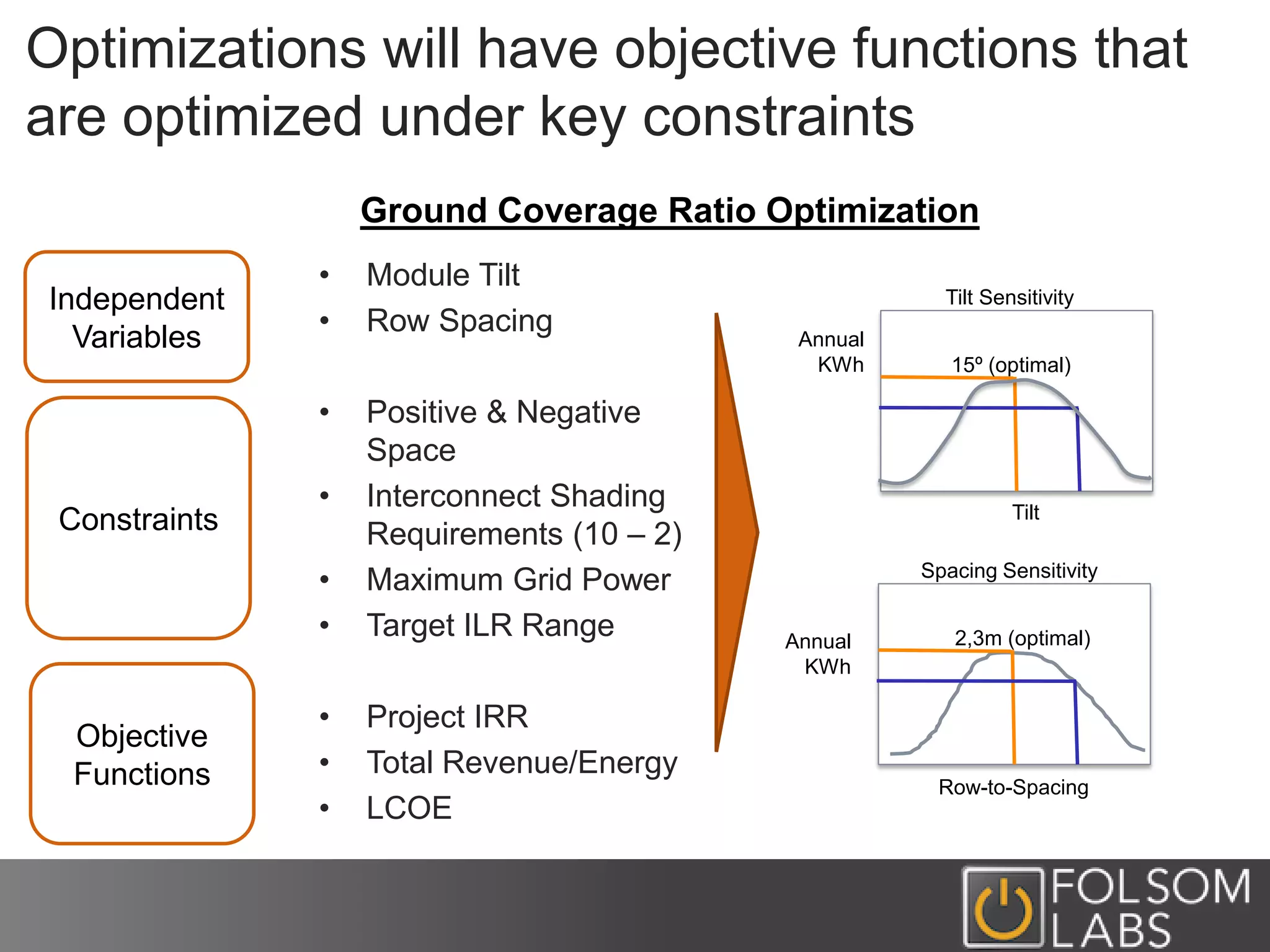

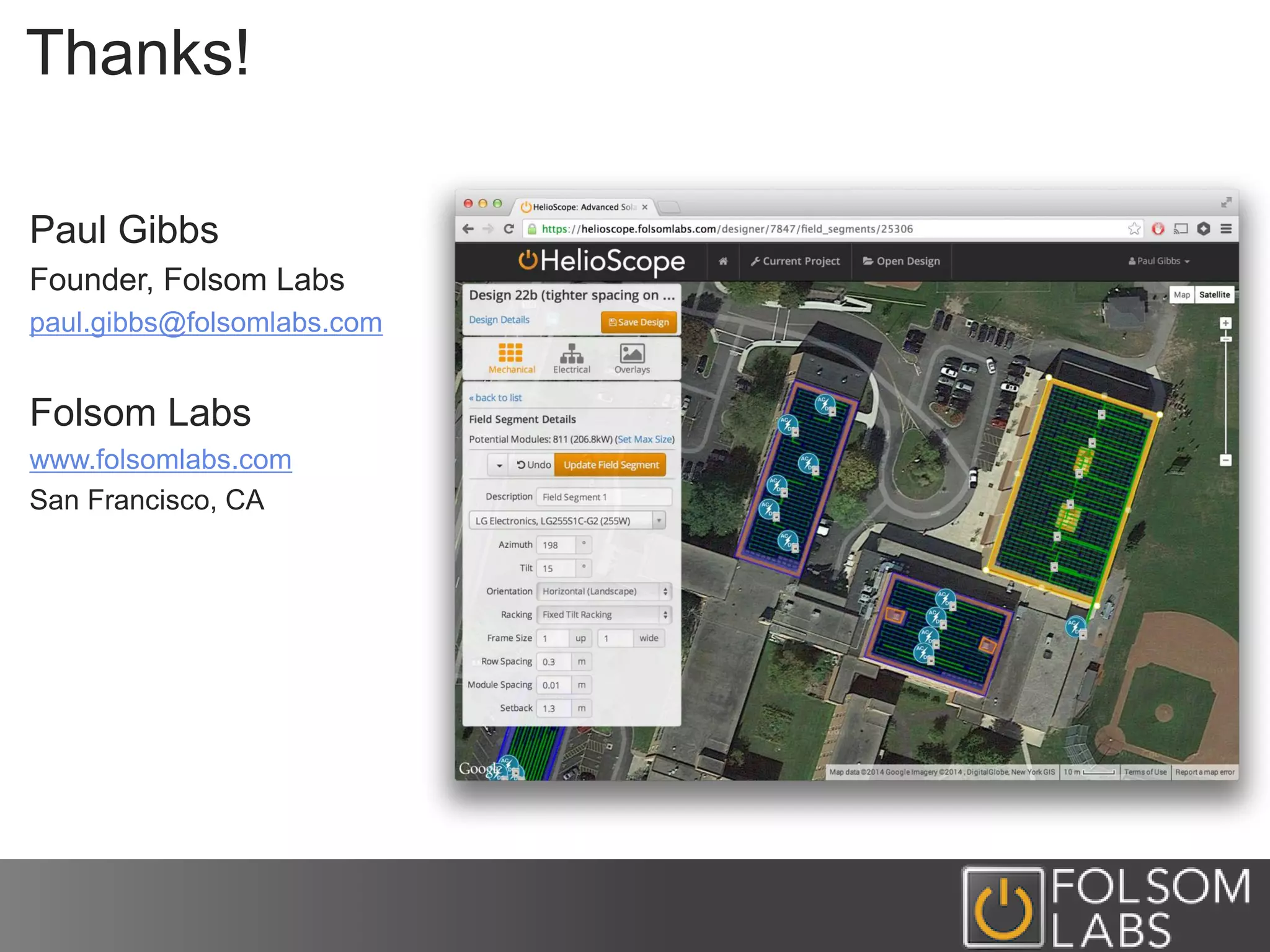

The document discusses optimizing photovoltaic (PV) designs using the Helioscope tool, highlighting its design-driven, cloud-based approach that facilitates detailed performance modeling and value engineering. It presents case studies on optimizing parameters such as the ground coverage ratio and shading impacts, emphasizing the economic benefits of optimizing the DC subsystem. Additionally, it outlines future enhancements to Helioscope through the DOE SunShot program, focusing on automated optimization and financial modeling.