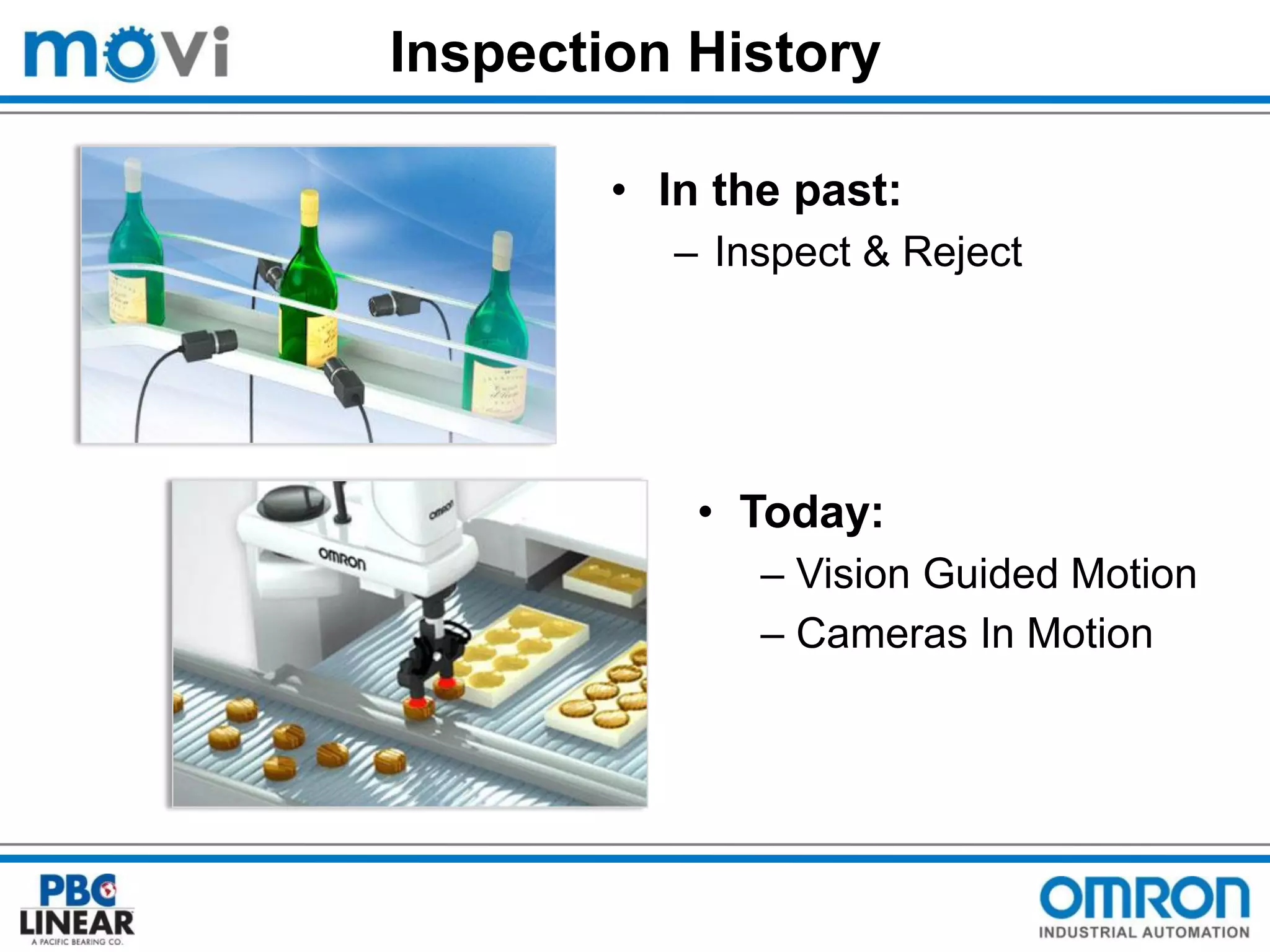

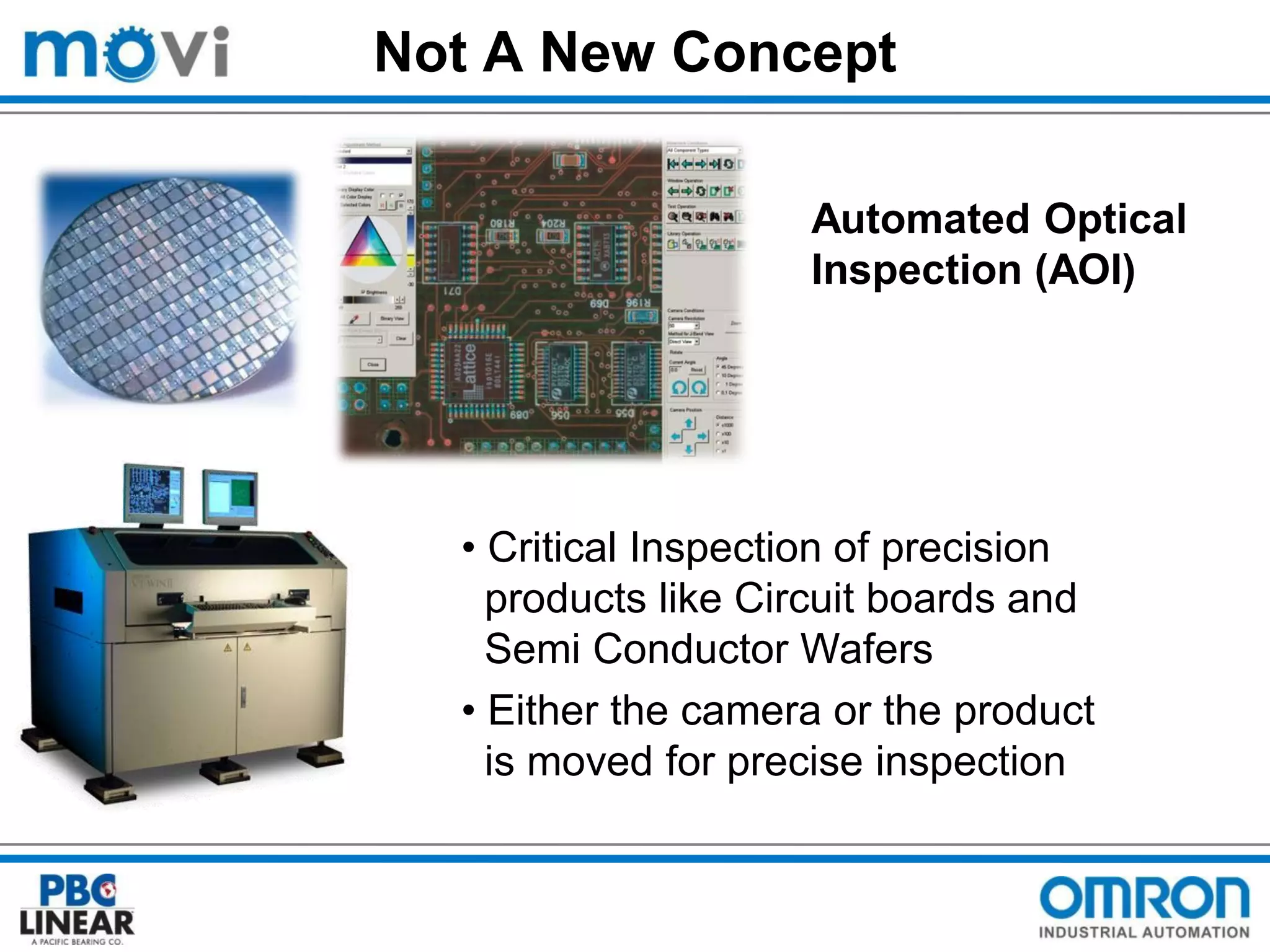

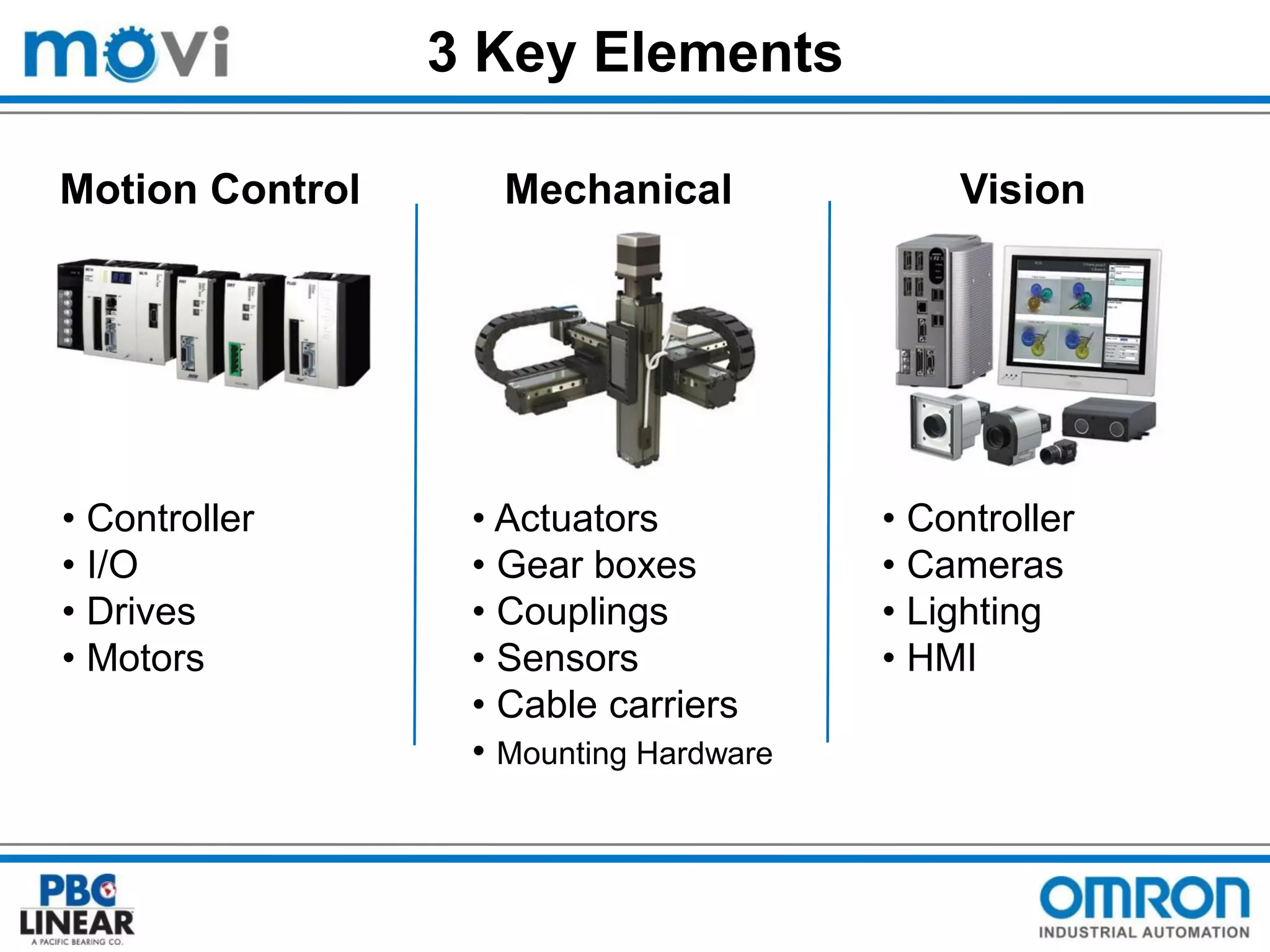

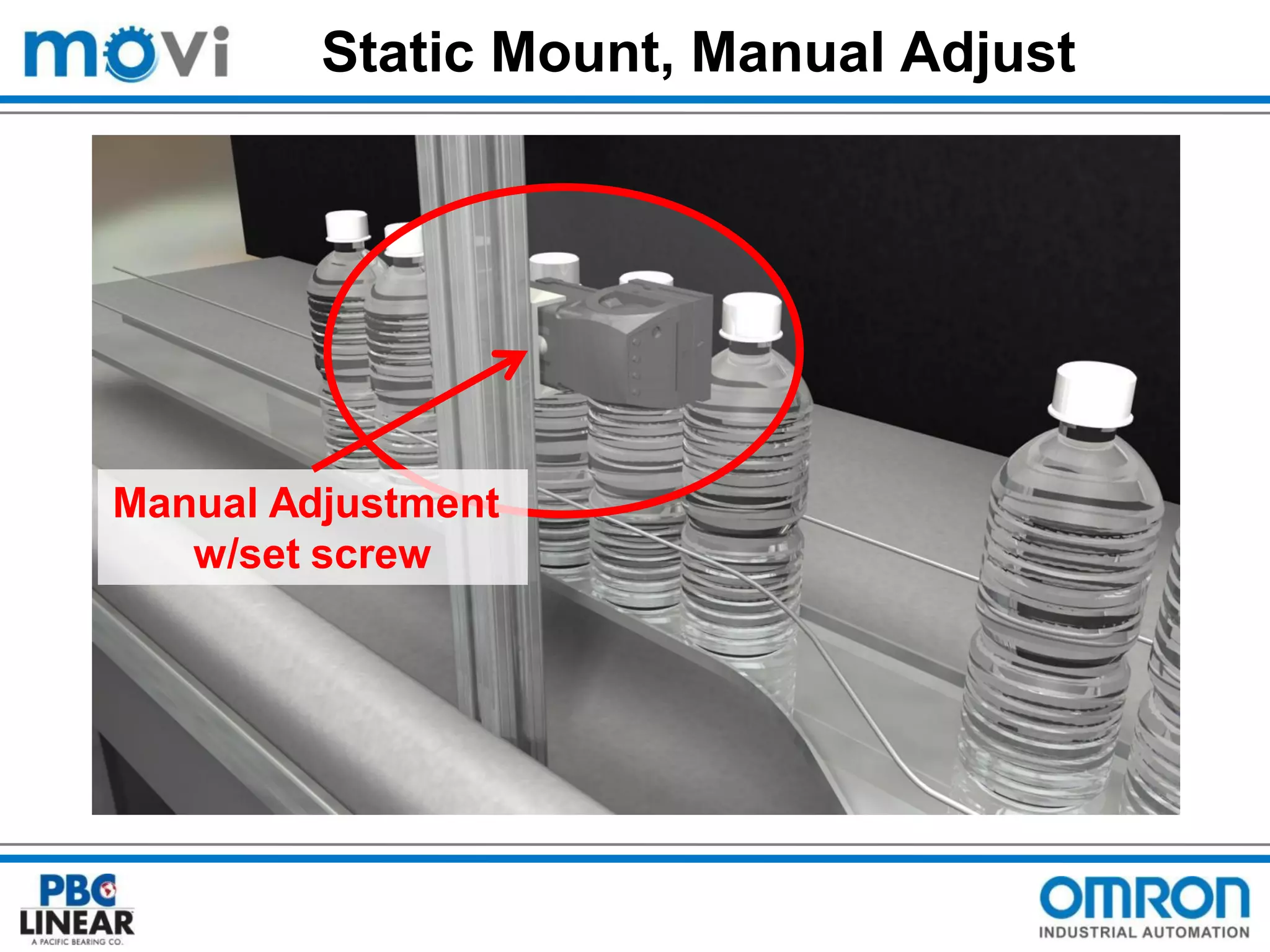

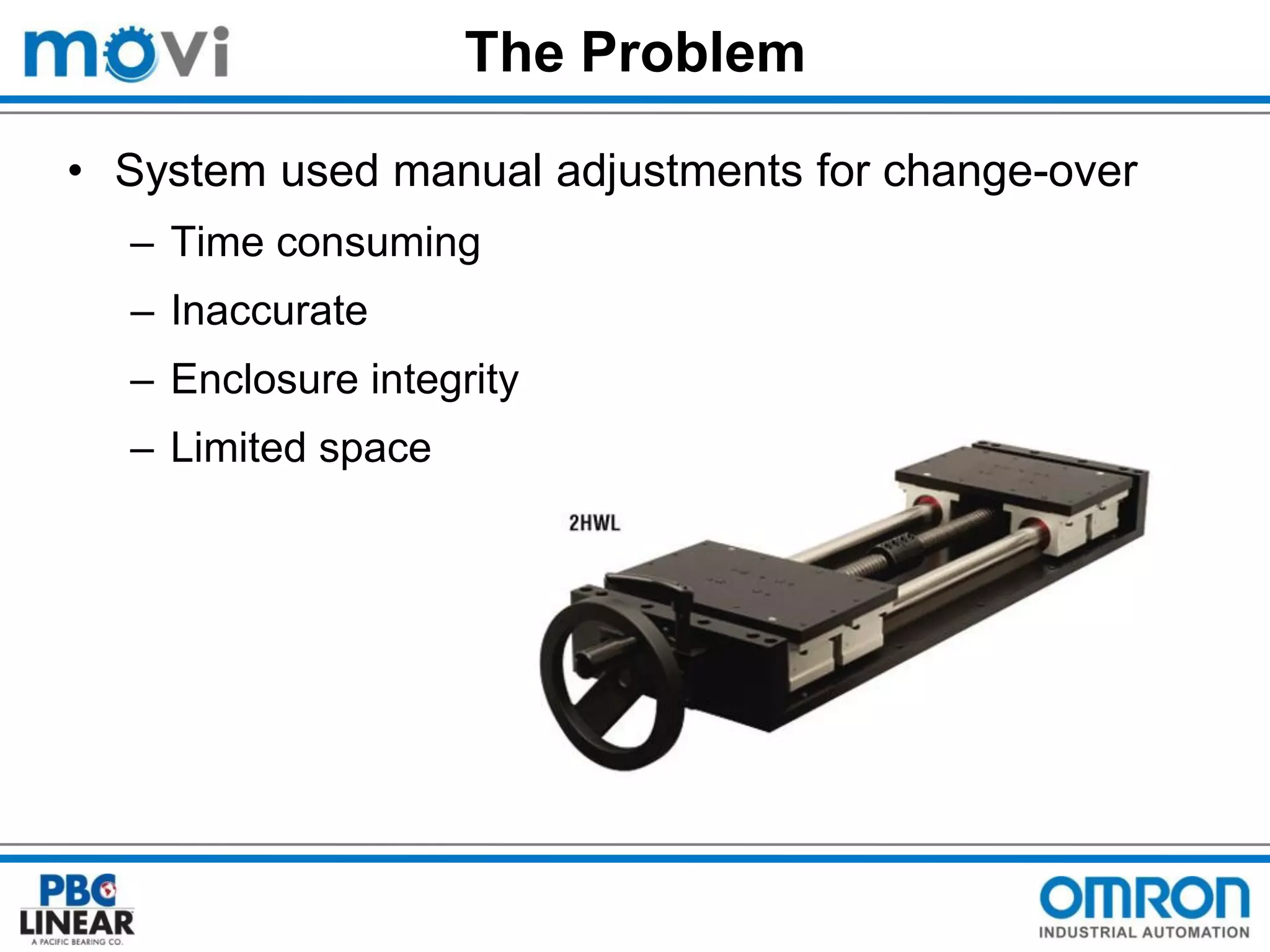

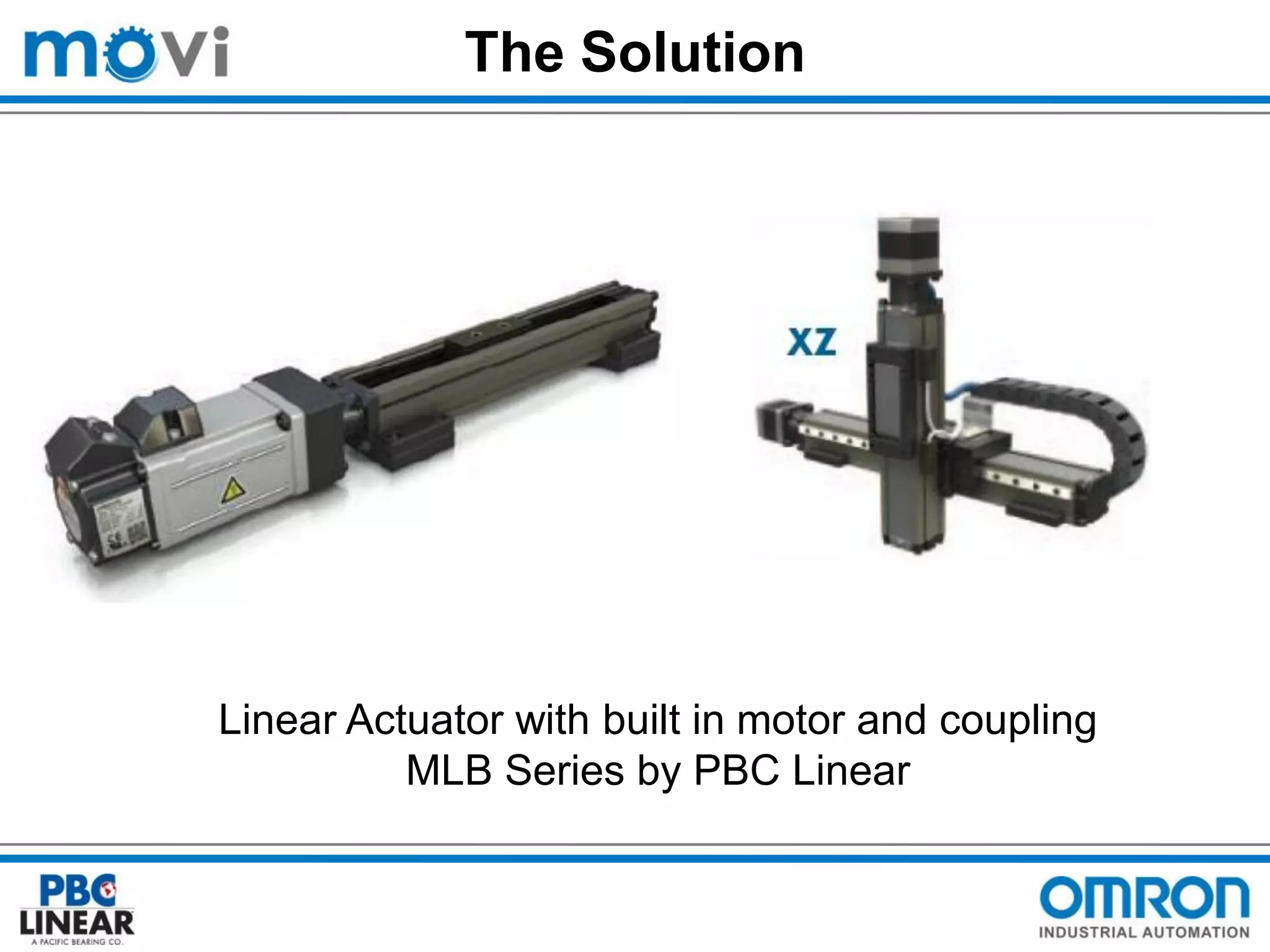

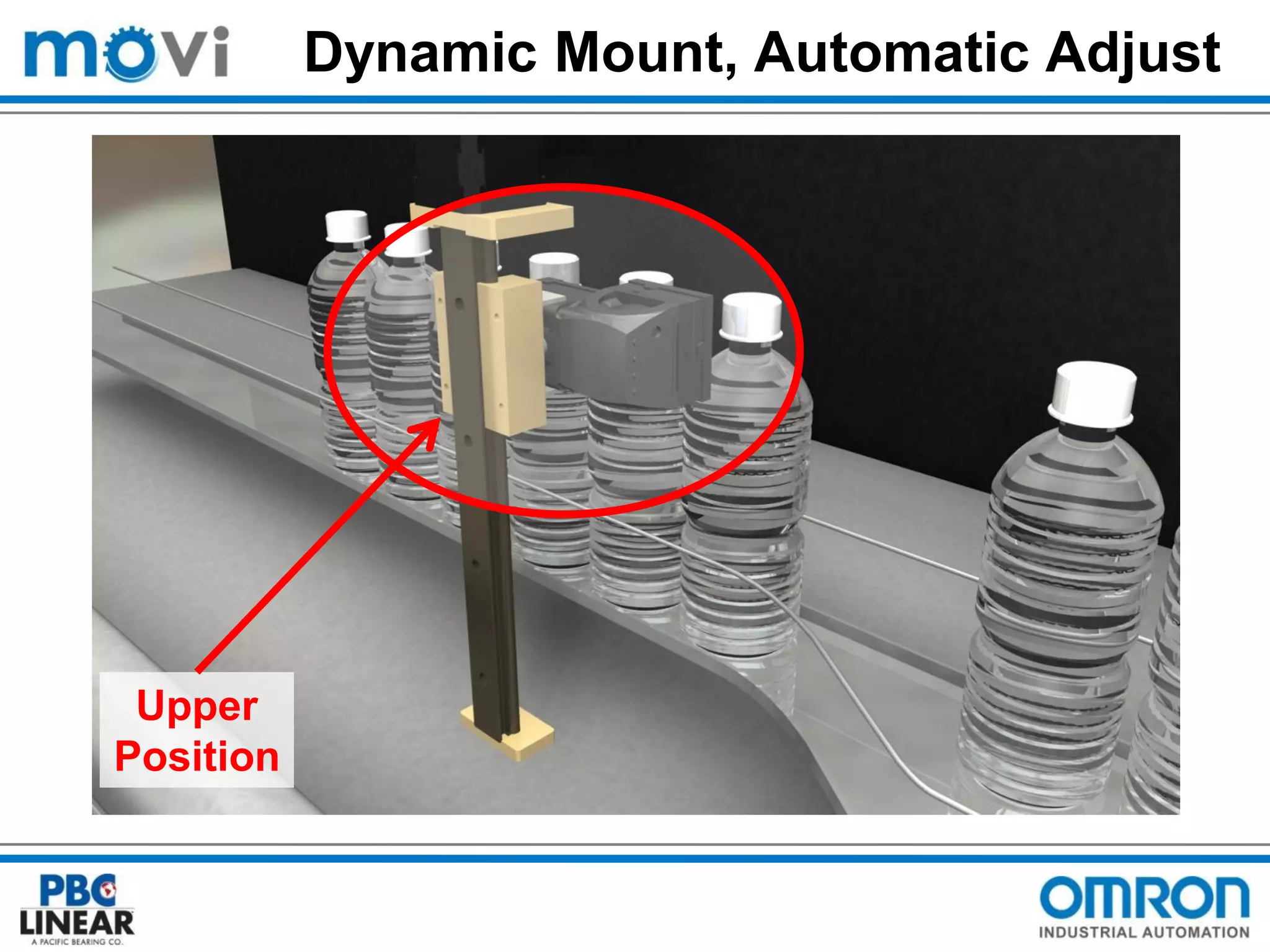

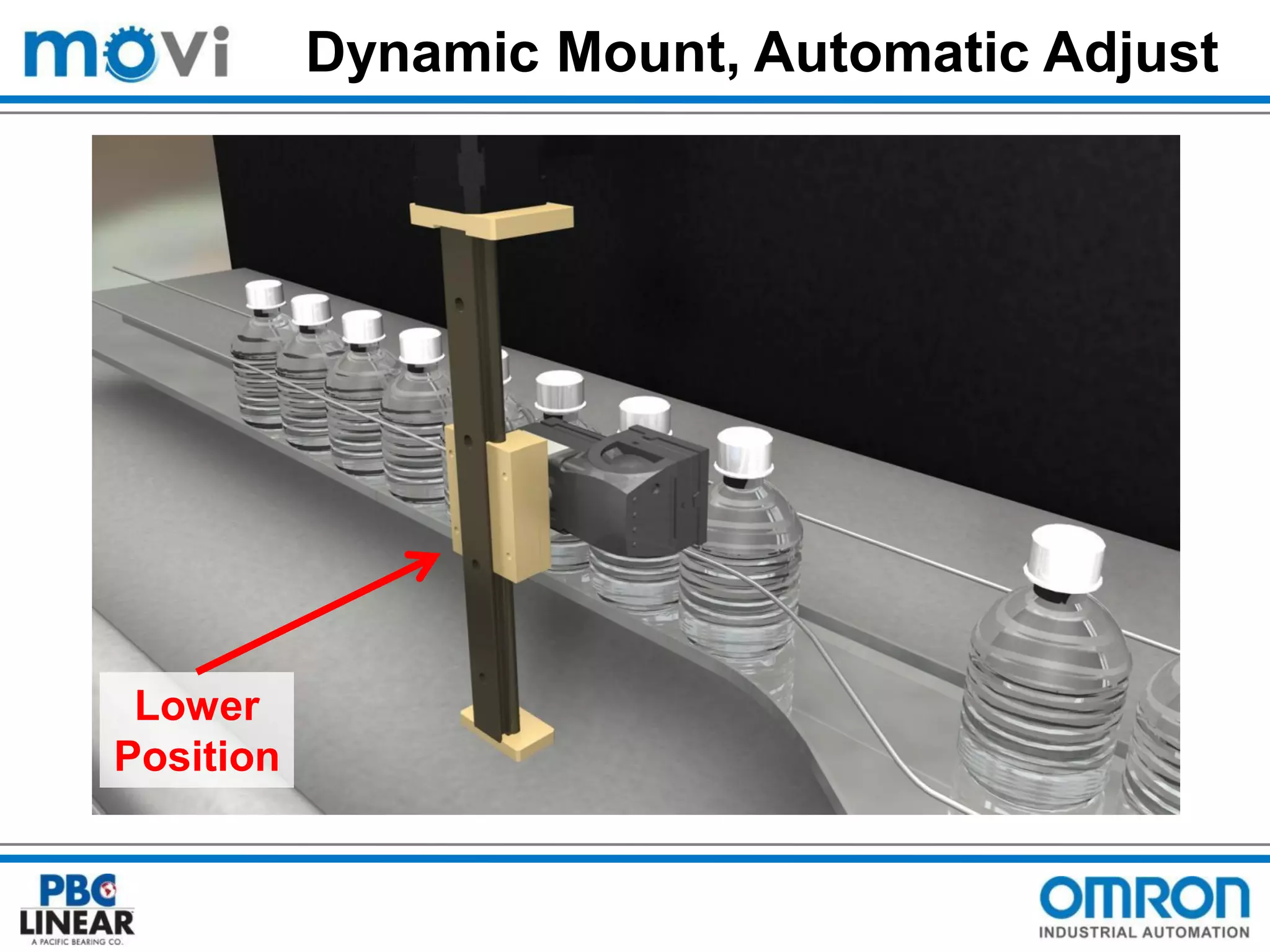

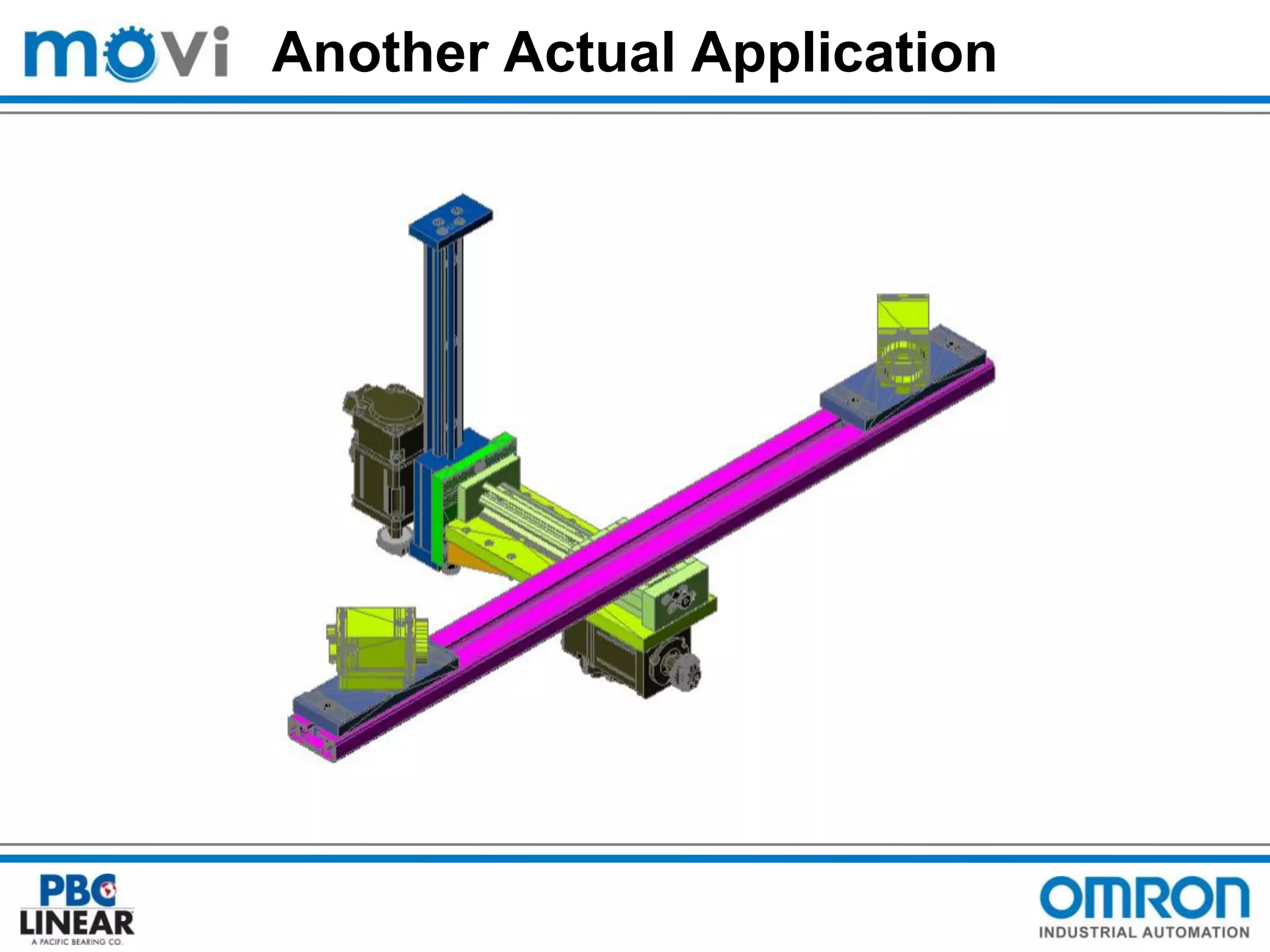

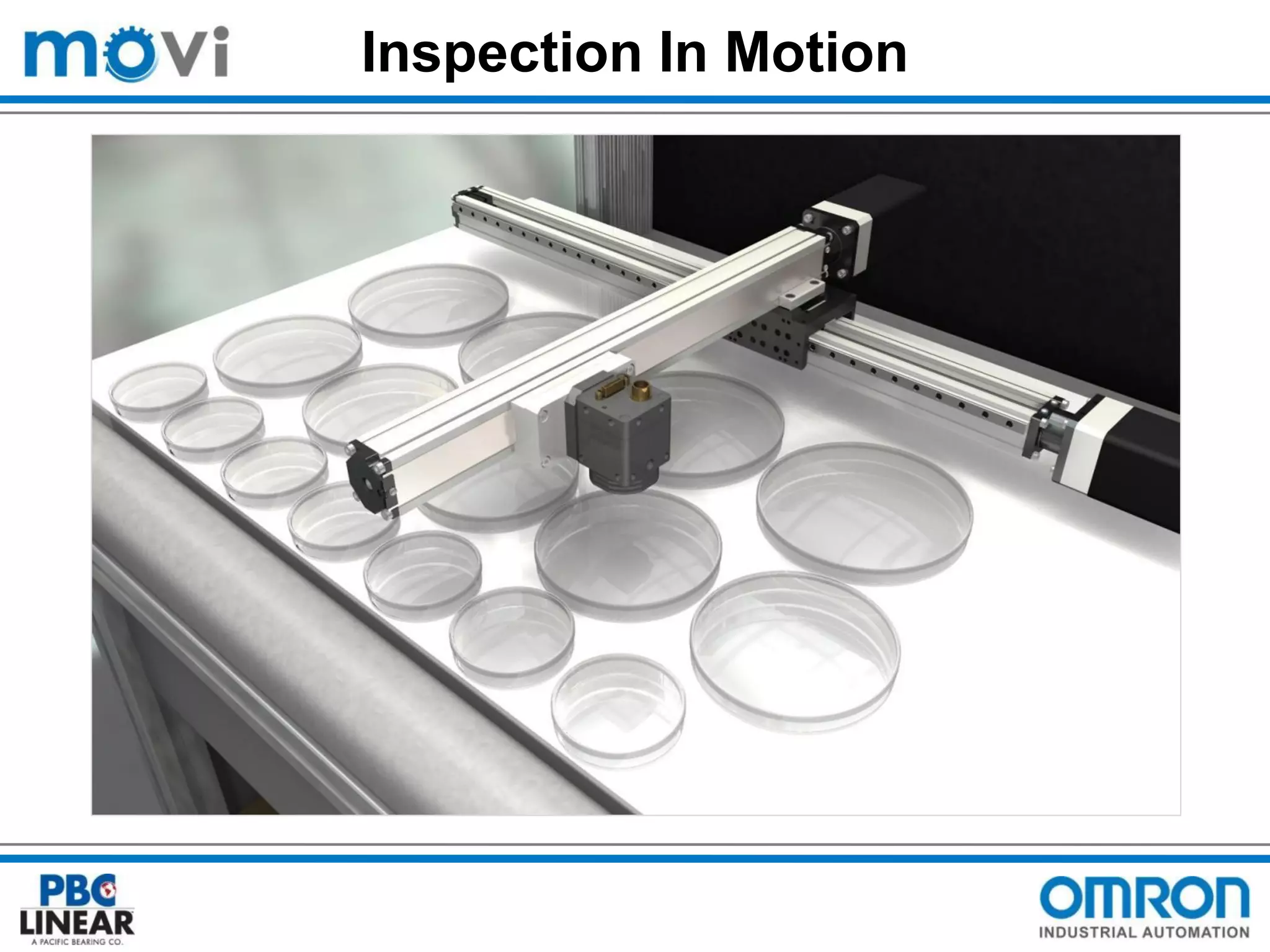

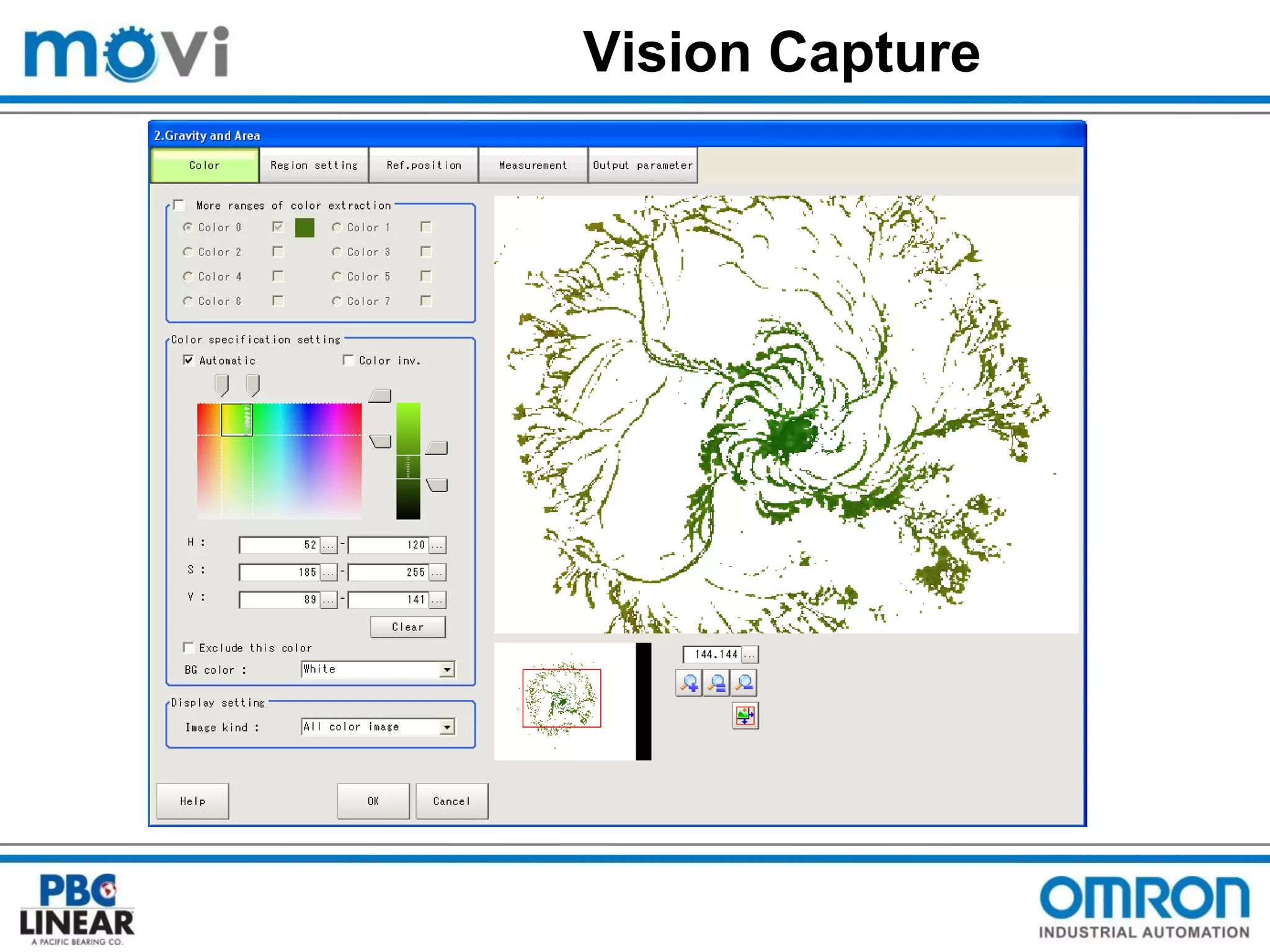

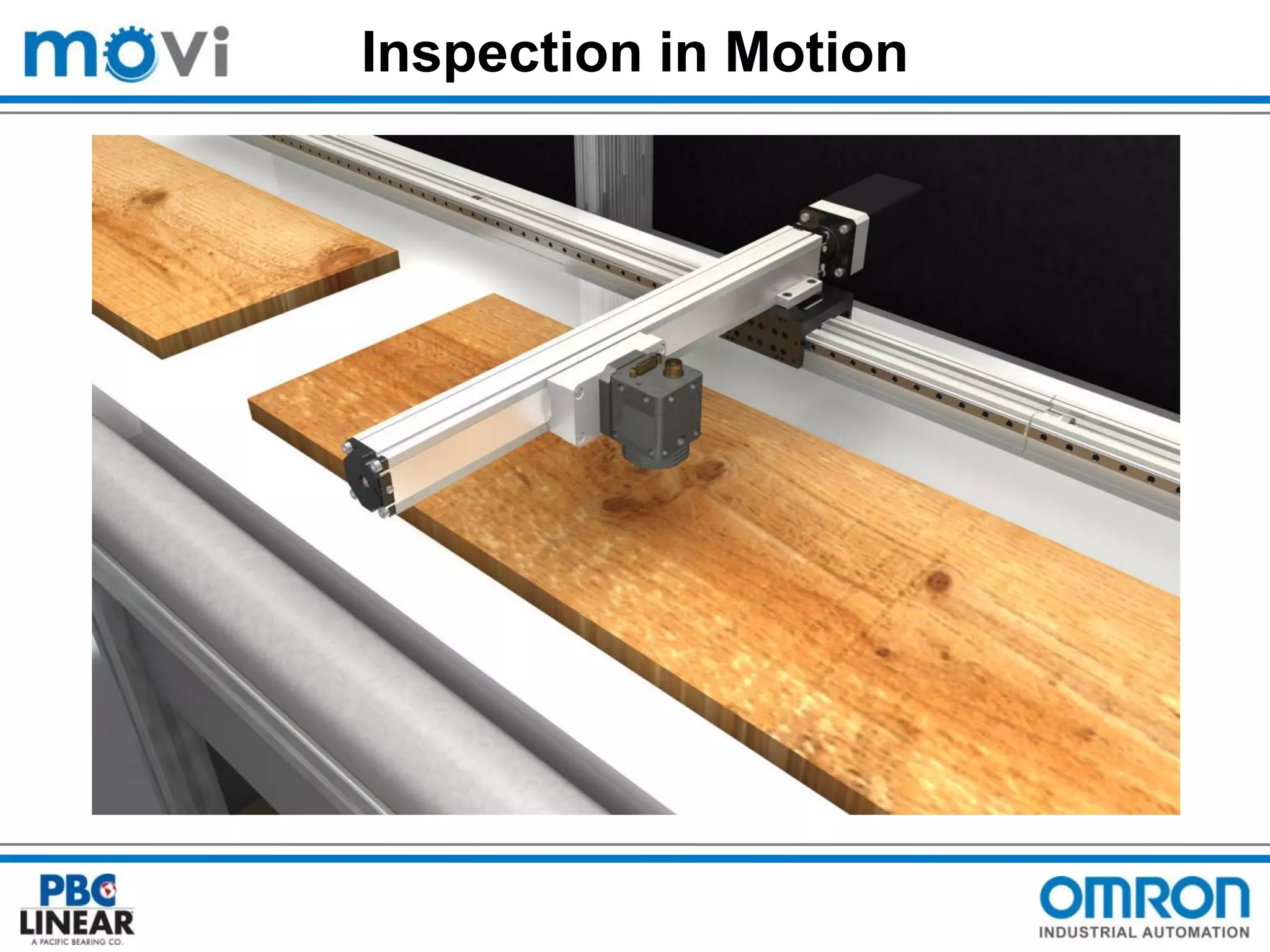

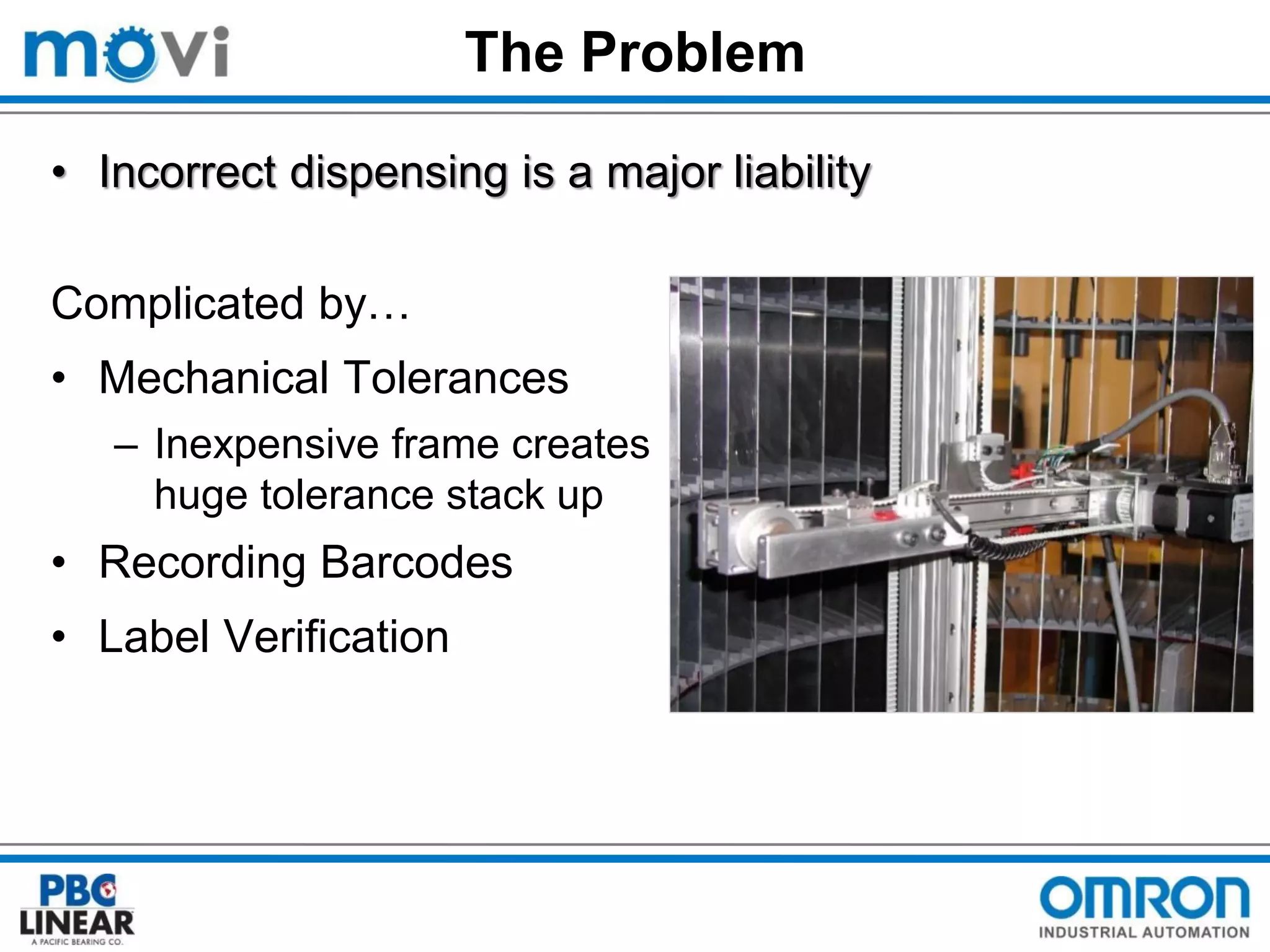

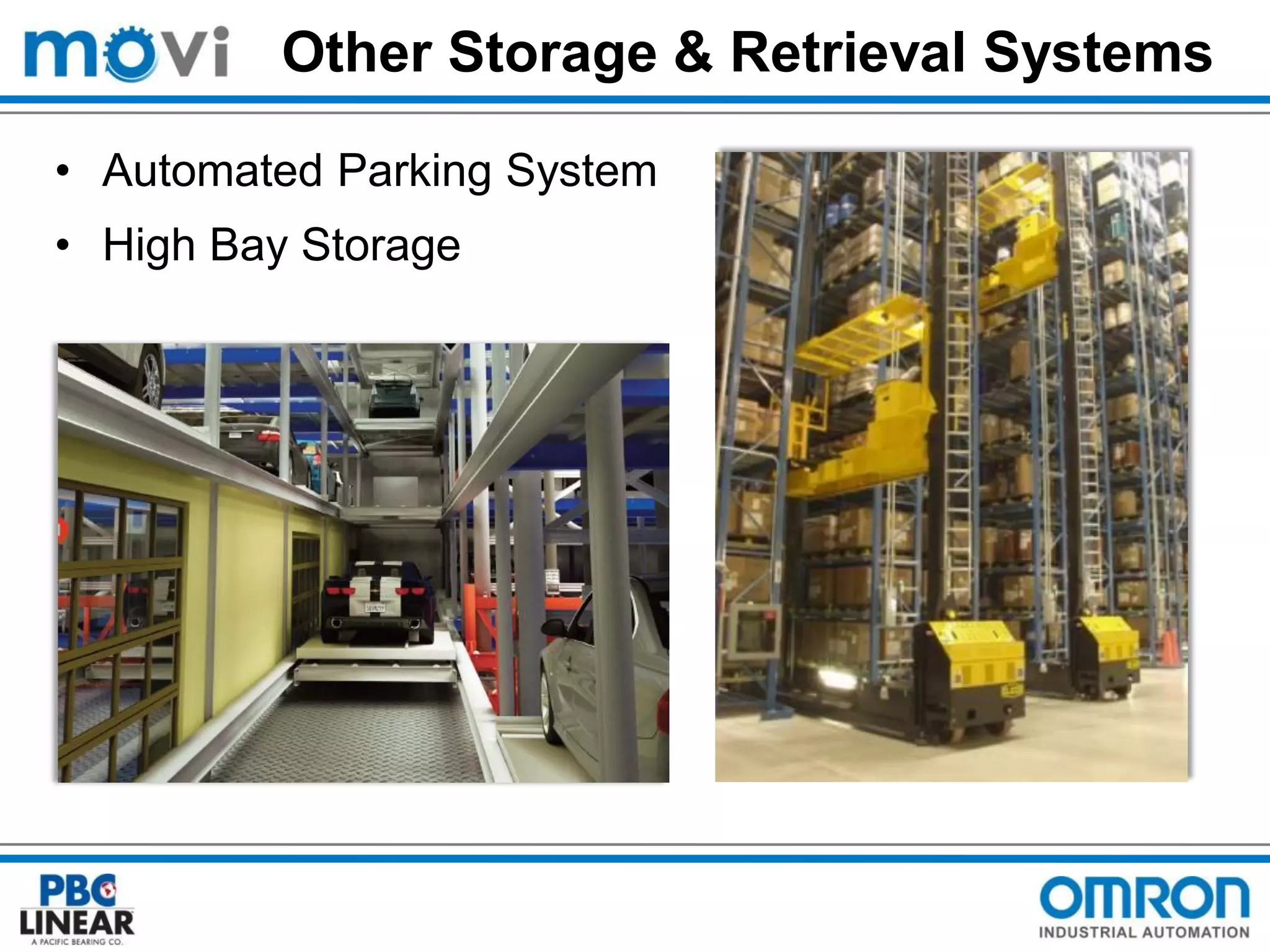

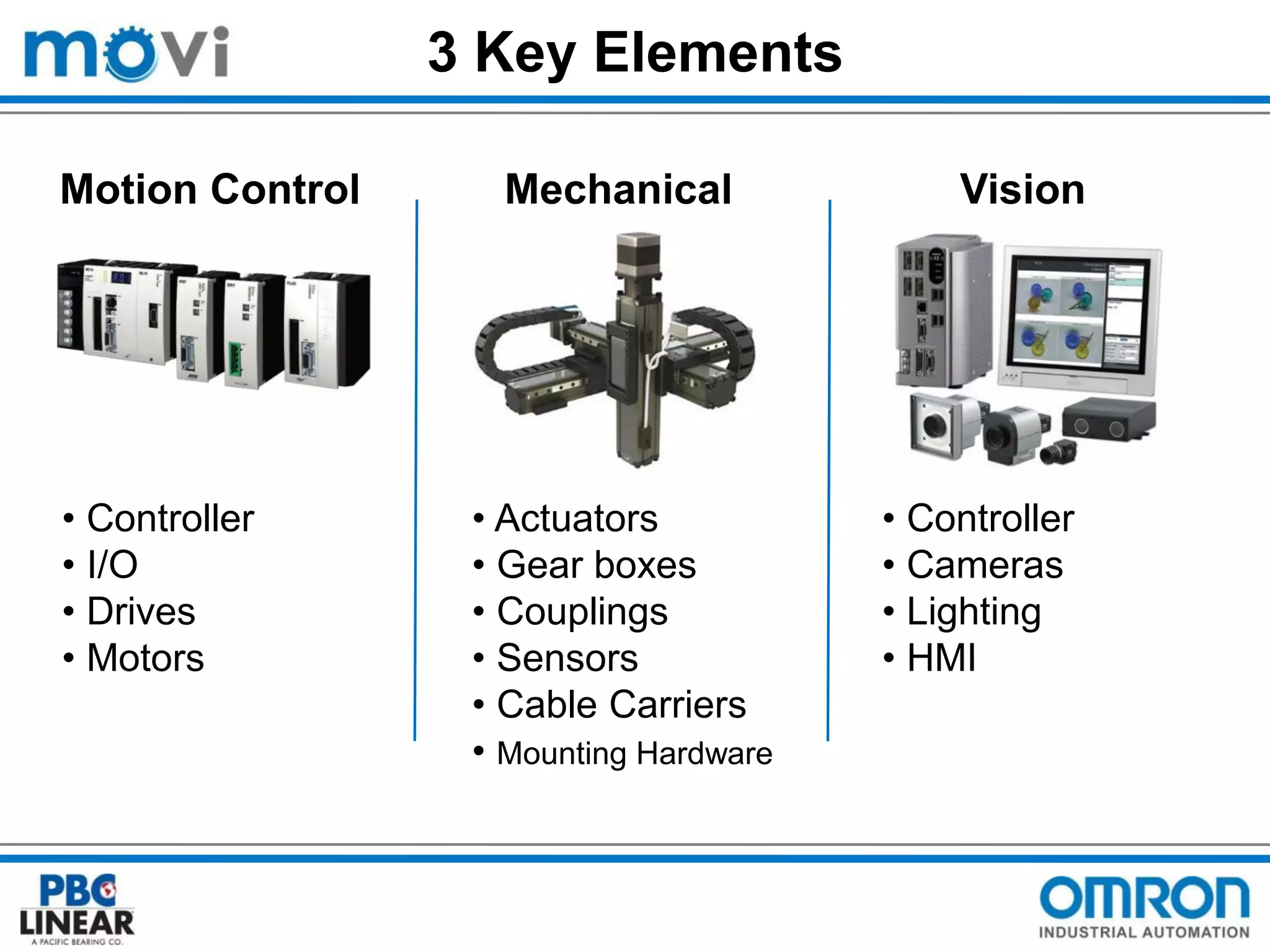

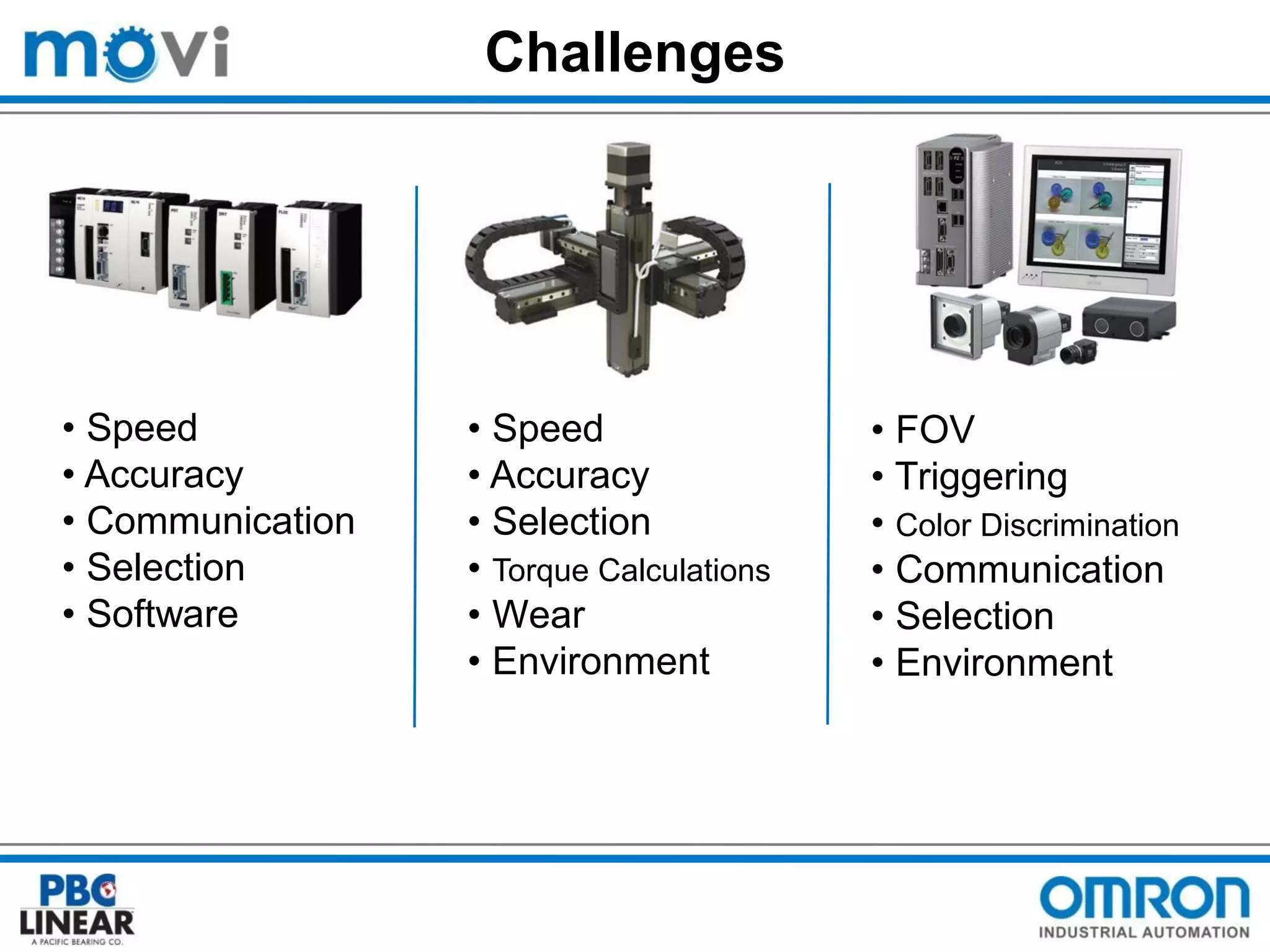

The document discusses the convergence of motion and vision technologies, highlighting the integration of these systems in various applications such as bottle inspection, lab automation, and automated storage and retrieval. Key challenges include speed, accuracy, and communication, while benefits encompass reduced design cycles and less technical conflict. It emphasizes collaboration between companies like Omron and PBC Linear to enhance product compatibility and functionality.