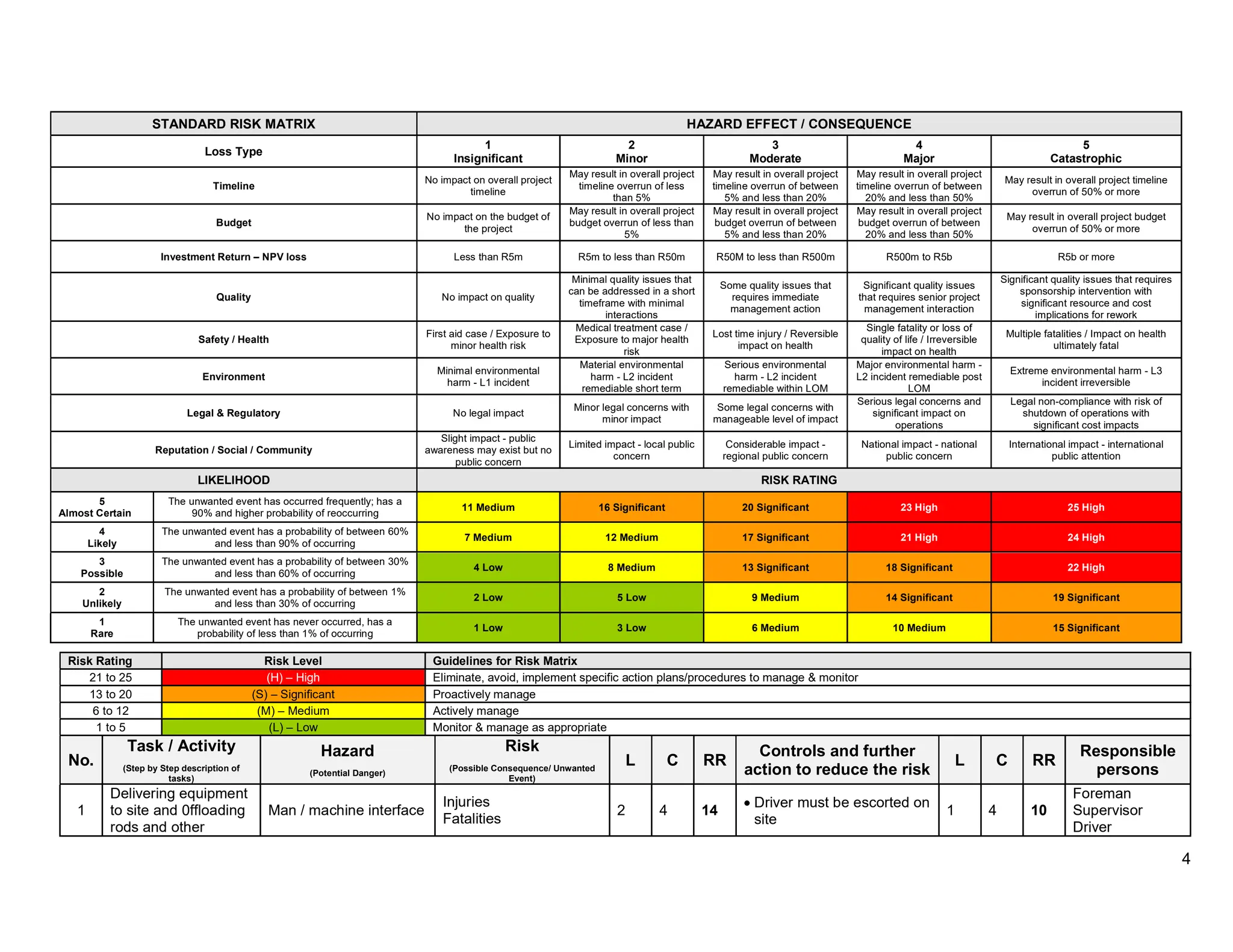

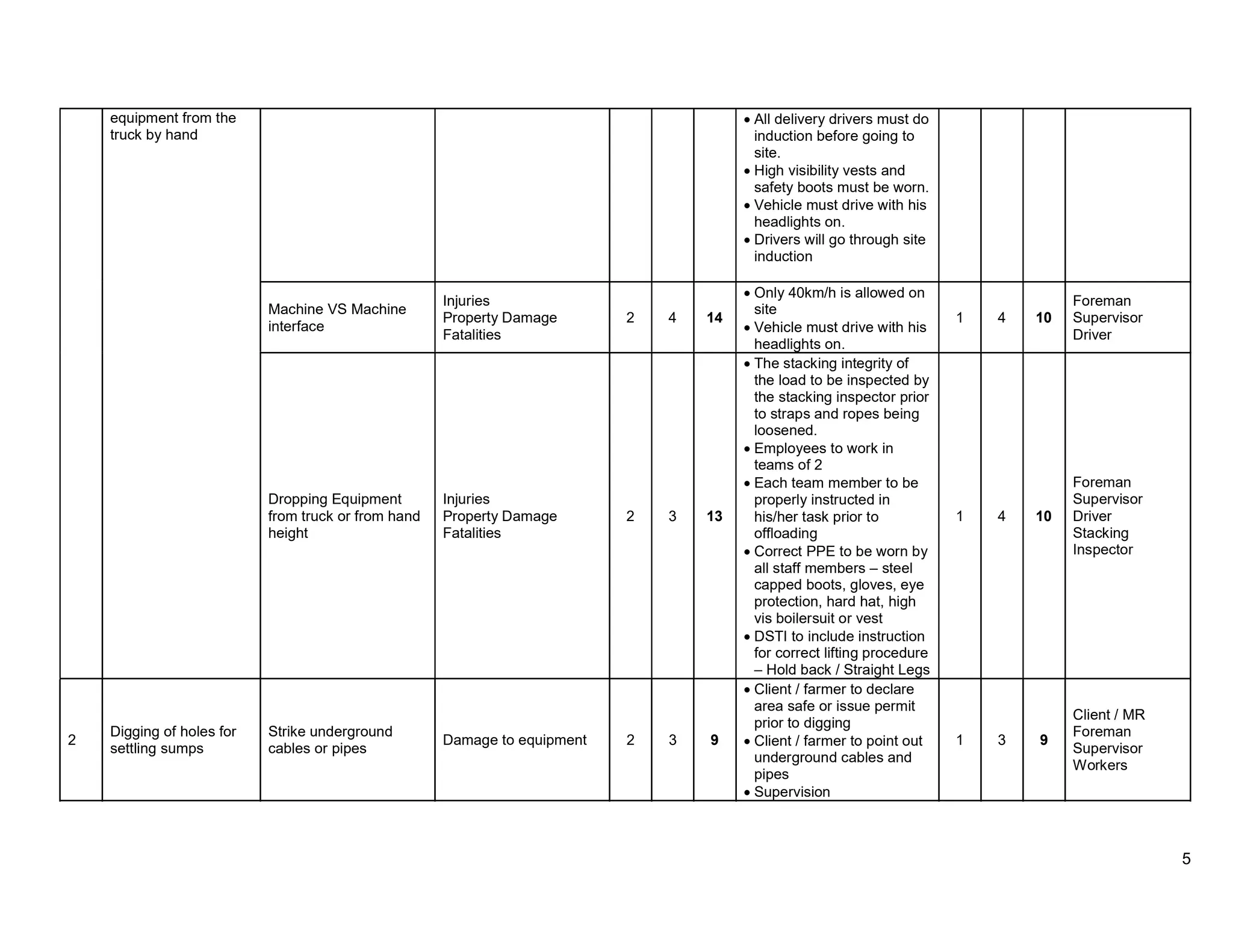

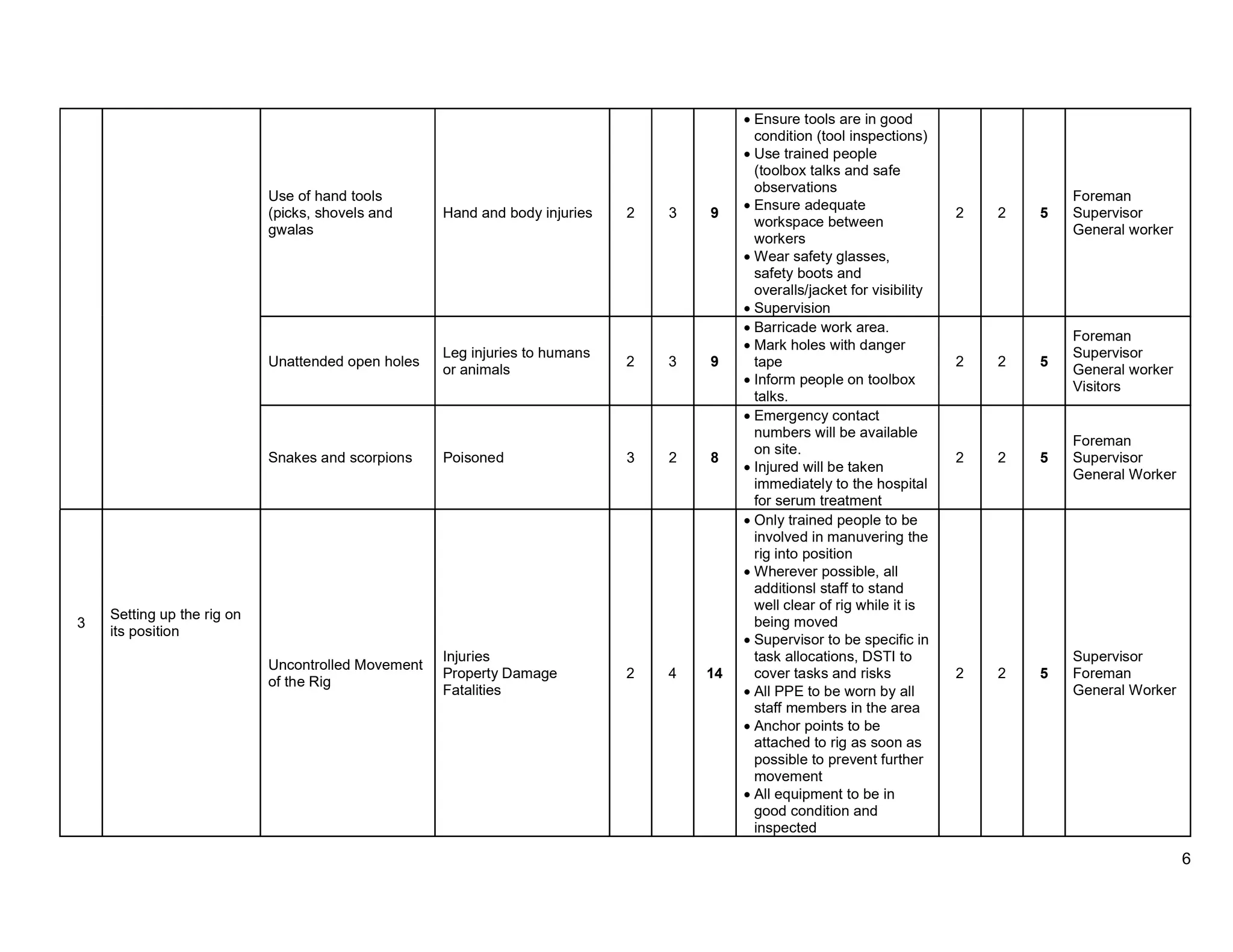

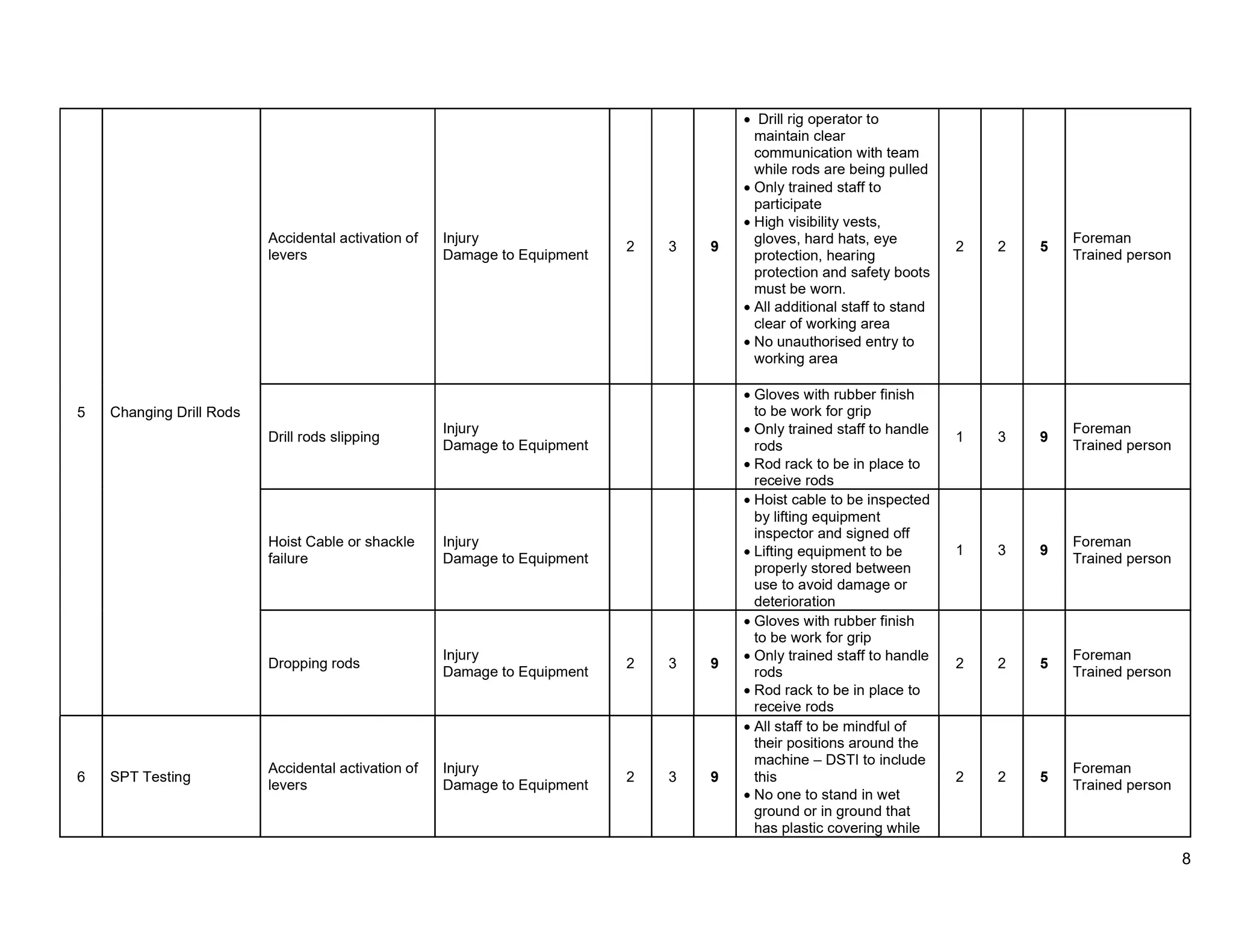

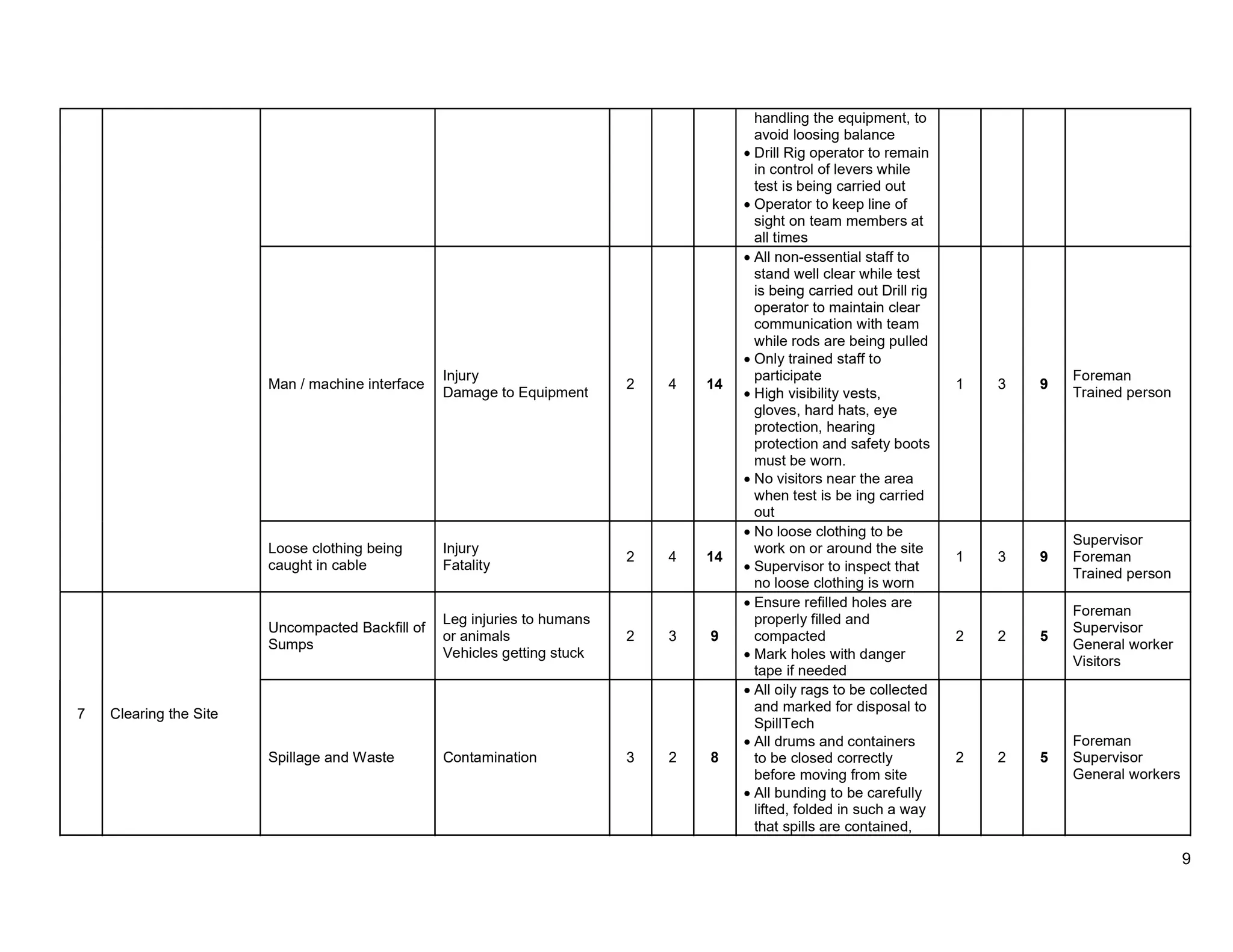

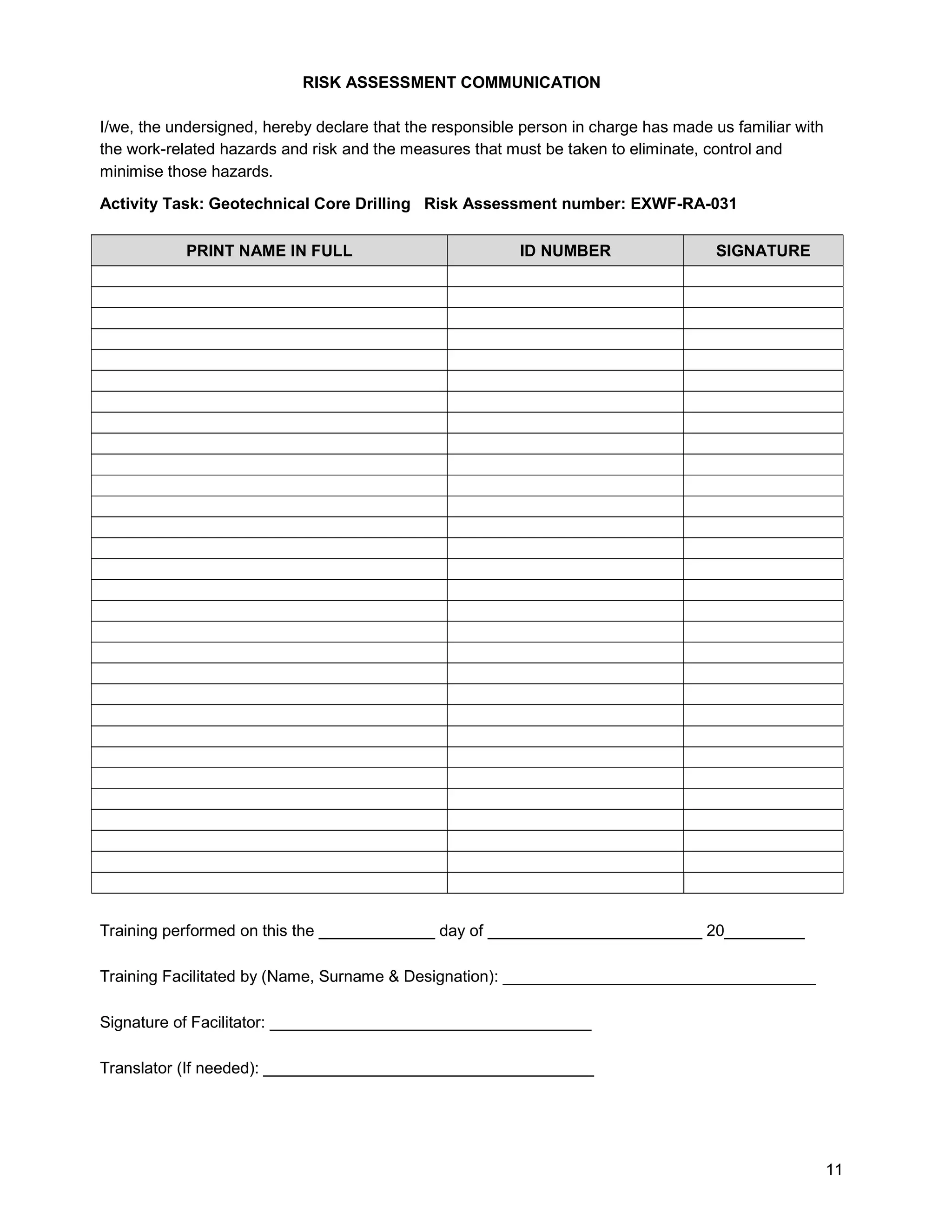

This risk assessment document covers geotechnical core drilling activities. It identifies potential hazards associated with tasks such as delivering equipment to site, drilling core holes, changing drill rods, and clearing the site. Hazards include injuries from man-machine interactions, falling objects, underground utilities, and environmental contamination. The document proposes controls such as inspections, designated work areas, and PPE to reduce risks. It provides a risk matrix for ranking hazards and ensures all involved are informed of risks and controls.