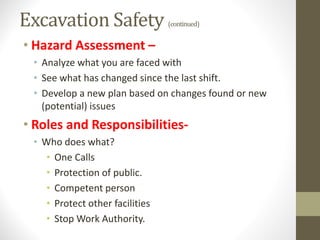

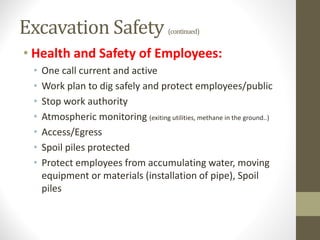

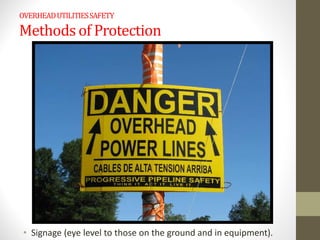

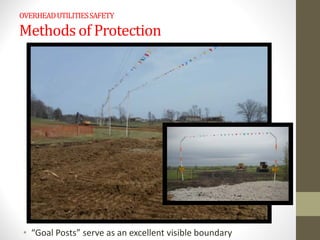

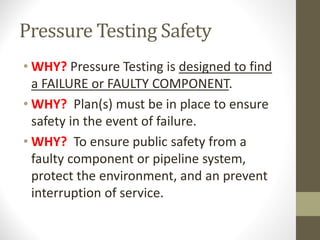

The document provides guidelines on improving safety in pipeline construction. It discusses an organization called INGAA that develops safety guidelines for pipeline operators, construction companies, and equipment manufacturers. The document outlines principles of an effective safety culture and provides guidelines on excavation safety, working under utility lines, and pressure testing. For each topic, it describes hazards and recommendations. Key aspects covered include hazard assessment, roles and responsibilities, and methods to protect employees and the public. Communication is emphasized as essential for safely applying these and other construction guidelines.