11 Piling Operations with Rebar Cage installation Risk Assessment Templates.docx

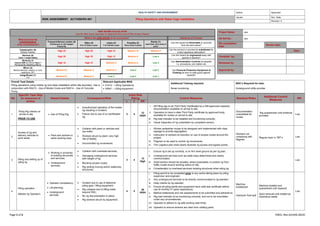

Project Name: xxx RA Ref No.: xxx RA compilation Date: Review date: Date: Compiled by: Reviewed by: Approved by: Overall Task Details Piling operations using mobile rig and rebar installation within site boundary. Use in conjunction with RA012 - Use of Mobile Crane and RA014 – Use of Concrete Pump. Relevant Applicable MAS: • 01412 – Lifting Operations; • 00941 – Lifting equipment Additional Training required: Noise monitoring NOC’s Required for task: Underground utility provider RISK SCORE CALCULATOR Use the Risk Score Calculator to Determine the Level of Risk of each Hazard What would be the CONSEQUENCE of an occurrence be? What is the LIKELIHOOD of an occurrence? Hierarchy of Controls Frequent/Almost certain (5) Continuous or will happen frequently Often (4) 6 to 12 times a year Likely (3) 1 to 5 times a year Possible (2) Once every 5 years Rarely (1) Less than once every 5 years Can the hazard be Eliminated or removed from the work place? Catastrophic (5) Multiple Fatalities High 25 High 20 High 15 Medium 10 Medium 5 Can the product or process be substituted for a less hazardous alternative? Serious (4) Class 1 single fatality High 20 High 16 High 12 Medium 8 Low 4 Can the hazard be engineered away with guards or barriers? Moderate (3) Class2 (AWI or LTI) or Class 1 Permanently disabling effects High 15 High 12 Medium 9 Medium 6 Low 3 Can Administration Controls be adopted I.e. procedures, job rotation etc. Minor (2) Medical attention needed, no work restrictions. MTI Medium10 Medium 8 Medium 6 Low 4 Low 2 Can Personal Protective Equipment & Clothing be worn to safe guard against hazards? Insignificant (1) FAI Medium10 Medium 4 Low 3 Low 2 Low 1 No Specific Task Step (In sequence of works) Hazard Details Consequence/Risk Initial Risk Rating Control Measures Residual Risks Additional Control Measures RR L C RR 1 Piling Rig checks on arrival to site PRIOR TO USE • Use of Piling Rig • Unauthorized operation of the mobile rig resulting in incident; • Failure due to use of un-certificated rig; 3 4 12 HIGH i. All Piling rigs to be Third Party Certificated by a DM approved inspector, documentation available on arrival to site; ii. Operators to have in-date Third Party certificate by approved body, available for review on arrival to site; iii. Rig load indicator to be installed and functioning correctly; iv. Visual inspection of rig undertaken by competent person; Documentation unavailable for review Rig quarantined until evidence provided Low 2 Access of rig and delivery vehicles to work areas • Plant and workers in same working area; • Collision with plant or vehicles and live traffic; • Workers struck by plant, very high risk of fatality; • Uncontrolled rig movements; i. Worker pedestrian routes to be designed and implemented with clear signage to provide segregation; ii. Instruction to workers at induction on use of access routes around the project; iii. Flagmen to be used to control rig movements; iv.

Recommended

Recommended

More Related Content

Similar to 11 Piling Operations with Rebar Cage installation Risk Assessment Templates.docx

Similar to 11 Piling Operations with Rebar Cage installation Risk Assessment Templates.docx (20)

More from Dwarika Bhushan Sharma

More from Dwarika Bhushan Sharma (20)

Recently uploaded

Recently uploaded (20)

11 Piling Operations with Rebar Cage installation Risk Assessment Templates.docx

- 1. HEALTH SAFETY AND ENVIRONMENT Author: Approved: RISK ASSESSMENT: ACT/HSE/RA 001 Piling Operations with Rebar Cage installation Issued: Rev. Date: Revision: 0 Page 1 of 2 HSEQ -Rev-01(JAN-2023) No Specific Task Step (In sequence of works) Hazard Details Consequence/Risk Initial Risk Rating Control Measures Residual Risks Additional Control Measures RR L C RR 1 Piling Rig checks on arrival to site PRIOR TO USE Use of Piling Rig Unauthorized operation of the mobile rig resulting in incident; Failure due to use of un-certificated rig; 3 4 12 HIGH i. All Piling rigs to be Third Party Certificated by a DM approved inspector, documentation available on arrival to site; ii. Operators to have in-date Third Party certificate by approved body, available for review on arrival to site; iii. Rig load indicator to be installed and functioning correctly; iv. Visual inspection of rig undertaken by competent person; Documentation unavailable for review Rig quarantined until evidence provided Low 2 Access of rig and delivery vehicles to work areas Plant and workers in same working area; Collision with plant or vehicles and live traffic; Workers struck by plant, very high risk of fatality; Uncontrolled rig movements; i. Worker pedestrian routes to be designed and implemented with clear signage to provide segregation; ii. Instruction to workers at induction on use of access routes around the project; iii. Flagmen to be used to control rig movements; iv. The Logistics plan shall clearly illustrate rig access and egress points; Workers not complying with flagmen Regular topic in TBT’s Low 3 Siting and setting up of piling rig Working in proximity to existing structures and services; Underground services; Collision with overhead services; Damaging underground services with weight of rig; Blocking access routes; Rig striking moving and/or stationary structures; 3 4 12 High i. Ensure rig is set up correctly, is on firm level ground as per rig plan; ii. Underground services such as cable trays determined and clearly communicated; iii. Solid barriers should be situated, where practicable, to protect rig from traffic routes around working radius of cab; iv. Consideration to overhead services/ existing structures when siting rig; Low 4 Piling operation (Mobile rig Operator) Operator competency; Lift planning; Underground services; Incident due to use of defective piling gear / lifting equipment; Rig collapse due to lifting loads beyond SWL; No rig documentation in place; Rig workers struck by equipment; 4 5 20 HIGH i. Piling permit to be completed prior to any works taking place by piling supervisor and engineer; ii. Any underground services to be directly communicated to rig operator; iii. Daily checks by rig operator; iv. Ensure all piling tackle and equipment have valid test certificate before use (6 monthly 3rd party inspections); v. Method statements and risk assessments to be submitted and adhered to; vi. Rig load indicator to be functioning correctly, and not to be overridden under any circumstances; vii. Operator to adhere to rig safe working load limits; viii. Operator to ensure workers are clear from rotating parts; Machine breakdown Hydraulic fluid spill Machine isolated and quarantined until repaired. Spoil removed and treated as hazardous waste Low Project Name: xxx RA Ref No.: xxx RA compilation Date: Review date: Date: Compiled by: Reviewed by: Approved by: Overall Task Details Piling operations using mobile rig and rebar installation within site boundary. Use in conjunction with RA012 - Use of Mobile Crane and RA014 – Use of Concrete Pump. Relevant Applicable MAS: 01412 – Lifting Operations; 00941 – Lifting equipment Additional Training required: Noise monitoring NOC’s Required for task: Underground utility provider RISK SCORE CALCULATOR Use the Risk Score Calculator to Determine the Level of Risk of each Hazard What would be the CONSEQUENCE of an occurrence be? What is the LIKELIHOOD of an occurrence? Hierarchy of Controls Frequent/Almost certain (5) Continuous or will happen frequently Often (4) 6 to 12 times a year Likely (3) 1 to 5 times a year Possible (2) Once every 5 years Rarely (1) Less than once every 5 years Can the hazard be Eliminated or removed from the work place? Catastrophic (5) Multiple Fatalities High 25 High 20 High 15 Medium 10 Medium 5 Can the product or process be substituted for a less hazardous alternative? Serious (4) Class 1 single fatality High 20 High 16 High 12 Medium 8 Low 4 Can the hazard be engineered away with guards or barriers? Moderate (3) Class2 (AWI or LTI) or Class 1 Permanently disabling effects High 15 High 12 Medium 9 Medium 6 Low 3 Can Administration Controls be adopted I.e. procedures, job rotation etc. Minor (2) Medical attention needed, no work restrictions. MTI Medium10 Medium 8 Medium 6 Low 4 Low 2 Can Personal Protective Equipment & Clothing be worn to safe guard against hazards? Insignificant (1) FAI Medium10 Medium 4 Low 3 Low 2 Low 1

- 2. HEALTH SAFETY AND ENVIRONMENT Author: Approved: RISK ASSESSMENT: ACT/HSE/RA 001 Piling Operations with Rebar Cage installation Issued: Rev. Date: Revision: 0 Page 2 of 2 HSEQ -Rev-01(JAN-2023) No Specific Task Step (In sequence of works) Hazard Details Consequence/Risk Initial Risk Rating Control Measures Residual Risks Additional Control Measures RR L C RR 5 Rebar cage fabrication Lifting operations; Manual handling; Cutting operations; Persons underneath load struck by materials; rebar bundles swinging / spinning uncontrolled; Falling materials; Damage to slings from sharp edges; Over-sailing of material over workers; Burns/cuts from grinding equipment; 4 4 16 High i. Risk Assessment 12 – mobile Crane to be adhered to regarding lifting of rebar bundles; ii. Workers to wear gloves when tying rebar cages; iii. Rebar cages to be fabricated on suitable supports, not scaffolding; iv. All electrical cutting equipment to be tested and safe to use. Operators shall wear safety glasses. Hot work permit required; Manual Handling regular topic in TBT’s Low 5 Pile case and rebar cage lifting operations Use of Piling Rigs; Use of mobile crane for rebar cages; Persons underneath load struck by materials; Persons falling into open bore holes; Pile cases and rebar cages swinging / spinning uncontrolled; Falling materials; Damage to slings from sharp edges; Over-sailing of piling material over live traffic routes; Hearing damage; Noise pollution to local residents; Proximity of live traffic routes; Damage to structure due to vibration from operation; Striking underground services causing injury/damage/isolation; Injury to personnel from rotating parts; Noise in urban areas; Environmental issues; Refilling of equipment; Storage of flammable substances; Use of generators; 4 5 20 High v. All piling operations shall be planned with rig and crane positioning schemes and method statements submitted and reviewed at least 5 days prior to work commencing; vi. Risk Assessment 12 – mobile Crane to be adhered to regarding lifting of rebar cages; vii. Municipality working restrictions, specific requirements and NOC’s to be adhered to; viii. All piling operations to have suitable barriers, fencing, hoarding and signage implemented to protect workers and the general public; ix. All known utilities drawings and plans regarding underground services to be investigated and marked prior to works commencing; x. Equipment to not have any guards removed during works, safe working distances to be maintained by workers; xi. All piling operations to comply with any Municipality imposed working restriction hours and noise levels; xii. All piling spoil to be removed from site following Municipality requirements, exit roads shall be maintained free of spoil; xiii. All open bore holes to be covered immediately with mesh guards and marked do not remove; xiv. In the event of maintenance - ground shall be suitably protected from oil/grease/chemical spillage and protection removed as hazardous waste; xv. Refuelling of equipment to be in designated areas, using correct filling trucks/bowsers. xvi. All fuel/combustive materials/chemicals shall be stored in approved storage areas; xvii. If single skin tanks are used then a sealed bund 110% capacity of the tank shall be installed; xviii. All piling staff shall wear hearing protection; Incident – falling materials Work in high winds; Striking unidentified underground services; Work stopped, area cleared and full investigation undertaken Cancel work operations in winds exceeded 40km/h; In the event of striking unidentified services all work to cease and emergency services contacted as required; Low