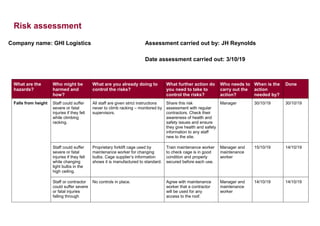

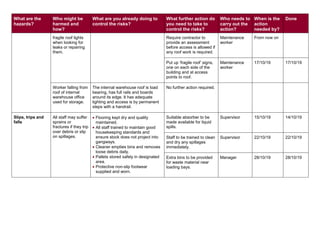

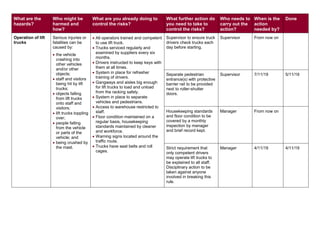

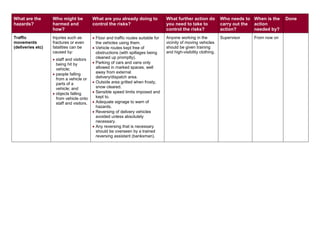

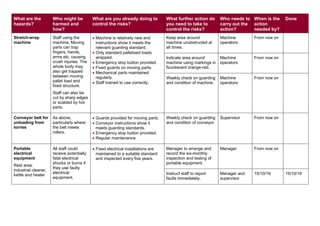

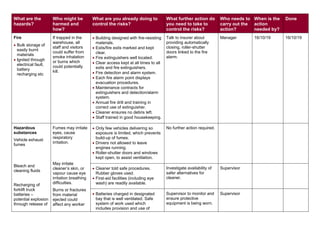

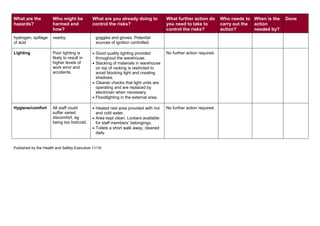

The warehouse manager carried out a risk assessment of the warehouse operations. They identified hazards such as falls from height, slips and trips, operation of lift trucks, and traffic movements. They evaluated the risks to workers and recorded existing controls. Further actions were identified like providing protective equipment and training workers. The manager will review the risk assessment when changes occur.