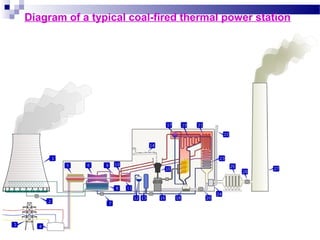

This document provides an overview of thermal power plants. It discusses the basic process of using steam to spin a turbine and generate electricity. Key components include the boiler, steam turbine, generator, and stack to remove gases. Efficiency is typically 33-48% with the rest of the energy exiting as waste heat. Thermal plants have relatively low initial costs but higher operating expenses than hydroelectric dams. The main disadvantages are air pollution and greenhouse gas emissions from burning fossil fuels.