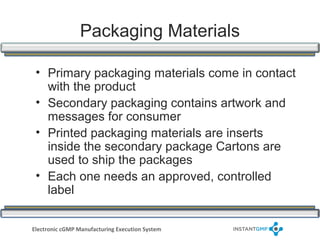

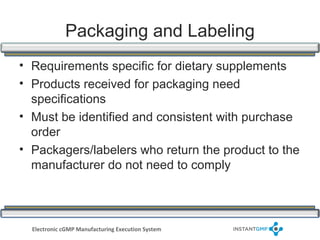

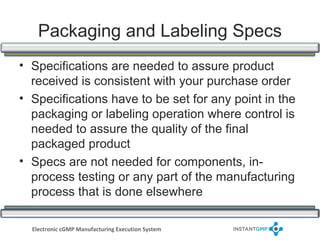

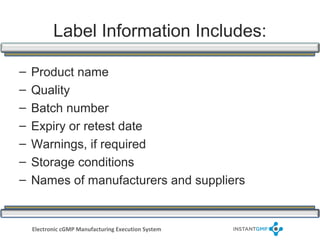

The document outlines compliance requirements for packaging and labeling of dietary supplements under cGMP (current Good Manufacturing Practices). It emphasizes the necessity of specifications, quality inspections, and unique identifiers to ensure product integrity, alongside the need for organized storage and handling. The InstantGMP MES is introduced as a software solution designed to facilitate adherence to these cGMP regulations.