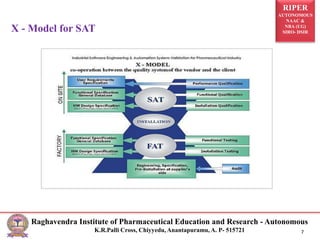

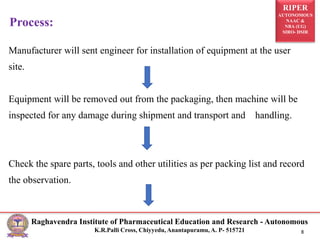

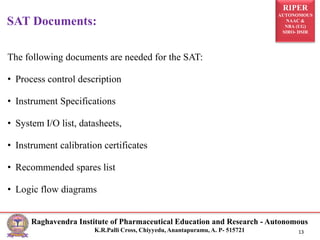

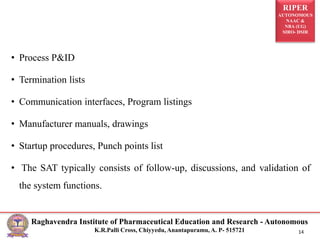

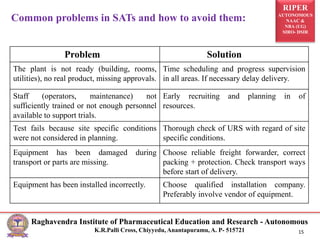

The document presents a seminar on Site Acceptance Tests (SAT) conducted as part of the curriculum requirement for a pharmaceutical education program. It details the objectives, processes, and elements involved in SAT to ensure equipment functionality and compliance with specifications before installation. Additionally, it outlines necessary documentation, common issues faced during SAT, and provides references for further reading.