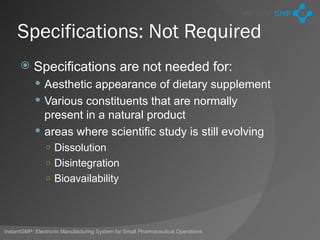

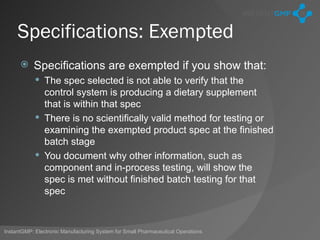

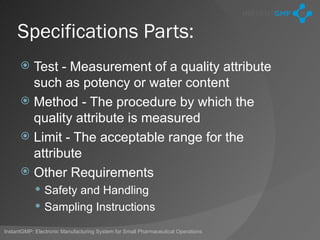

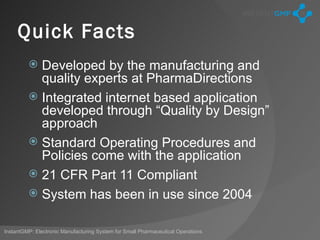

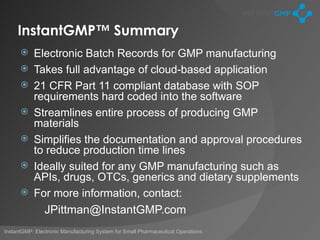

The document outlines GMP (Good Manufacturing Practices) requirements for dietary supplements, emphasizing compliance for manufacturers and distributors since 2007. It details necessary specifications for manufacturing, packaging, labeling, and quality control of dietary ingredients, including limits on contaminants and the necessity for pre-market reviews of new dietary ingredients. The InstantGMP electronic manufacturing system is highlighted as an efficient tool for ensuring GMP compliance and streamlining production processes in the dietary supplement industry.