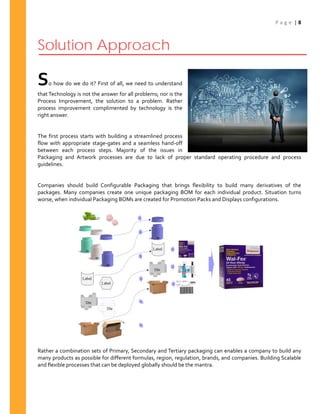

This document discusses integrating packaging, labeling, and artwork management processes with supply chain management. It outlines the business drivers of reducing time to market and ensuring regulatory compliance. It describes challenges like lack of coordination between teams and legacy systems. The document proposes building standardized processes, flexible packaging configurations, and using ERP systems' existing capabilities for artwork management instead of separate applications. Integrating these areas into a single solution can improve visibility, automation, and change management across the product development lifecycle.