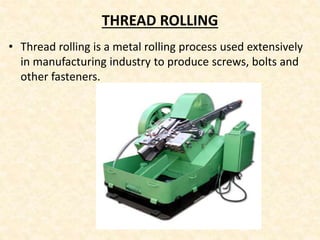

Sterling Tools Limited is a leading manufacturer of fasteners in India. It produces special, standard, chassis, and engine fasteners. The industrial training document describes Sterling's manufacturing process, which includes forging wire, forming heads through cutting, forming, and trimming, rolling threads, machining parts through turning and other operations, heat treating through hardening and tempering, electroplating for surface finishing, and implementing pollution controls and energy conservation efforts.