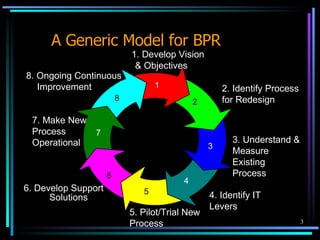

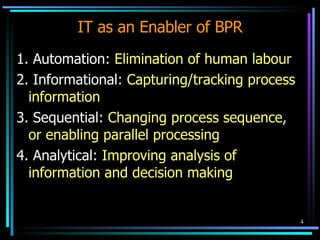

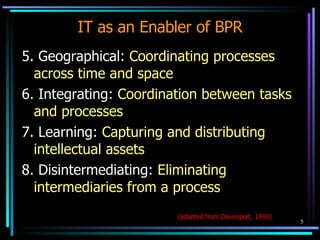

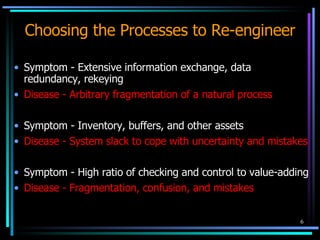

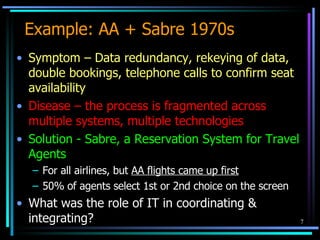

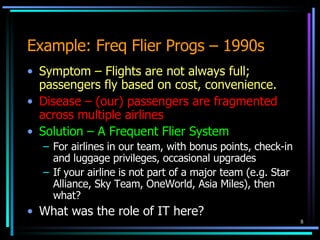

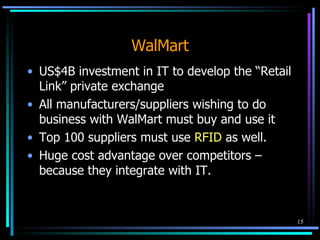

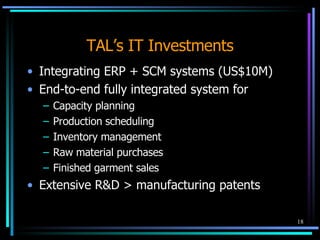

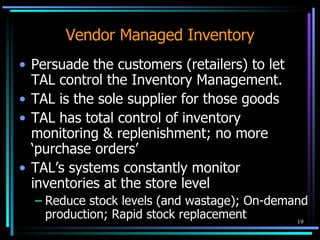

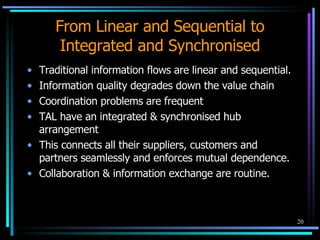

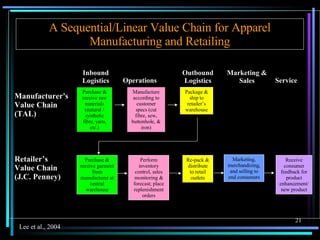

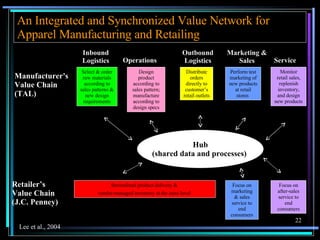

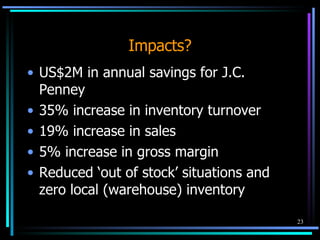

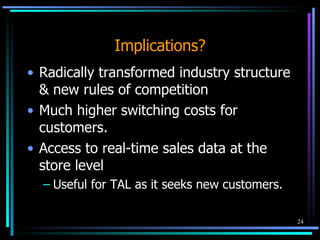

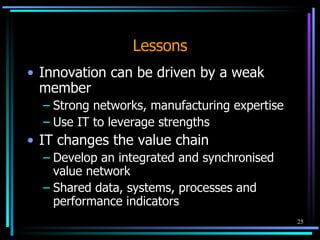

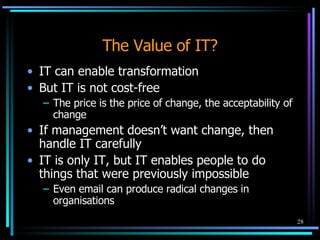

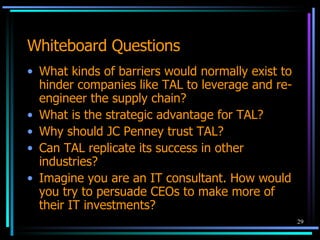

The document discusses how business process reengineering (BPR) can be enabled by information technology (IT). It provides a generic model for BPR and describes how IT can automate, integrate, and disintermediate processes. An example is given of how the apparel manufacturer TAL Group transformed its supply chain through IT investments like enterprise resource planning. This integrated TAL, its customers like JC Penney, and suppliers into a synchronized value network, improving inventory management, sales, and margins.