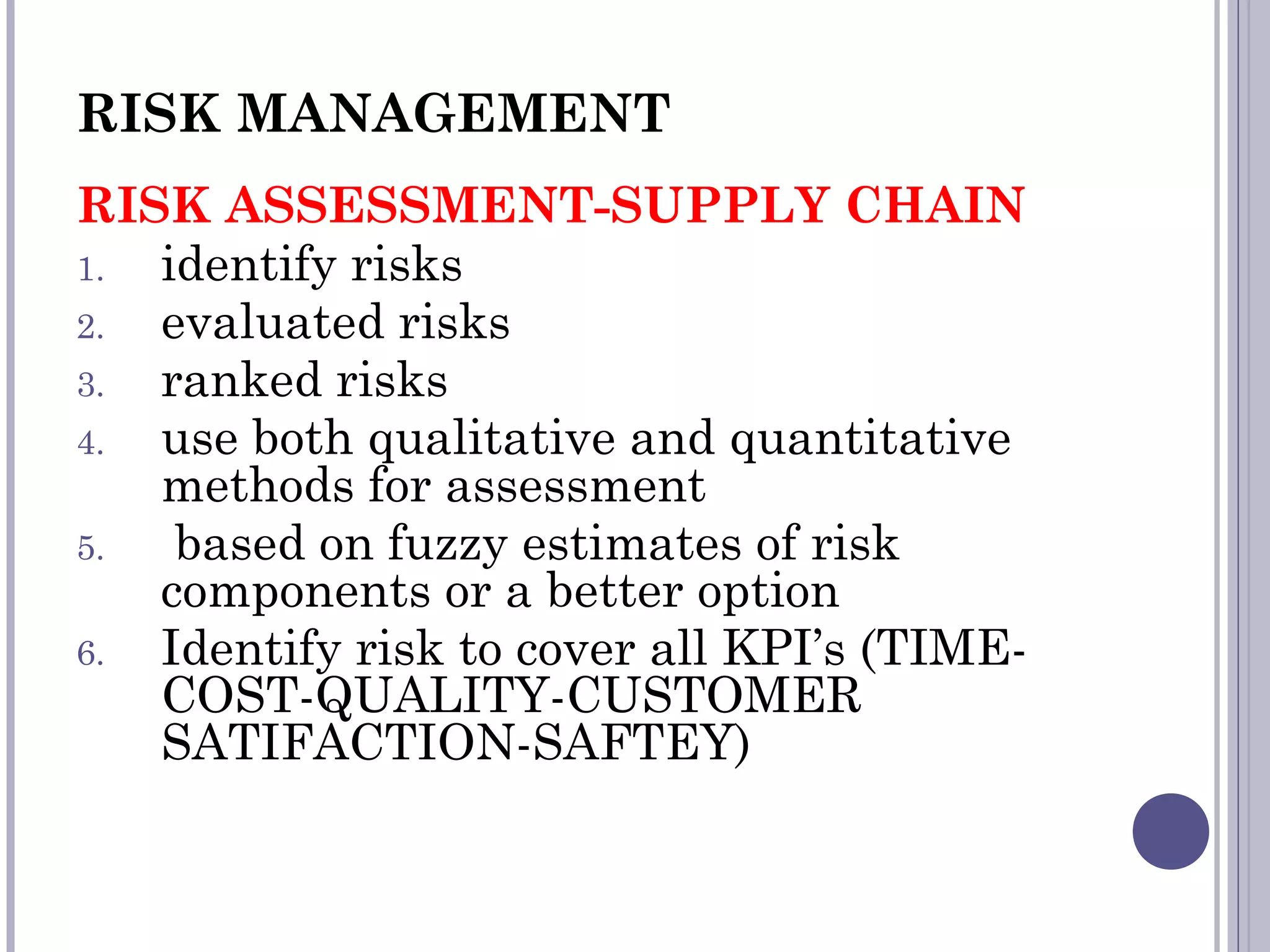

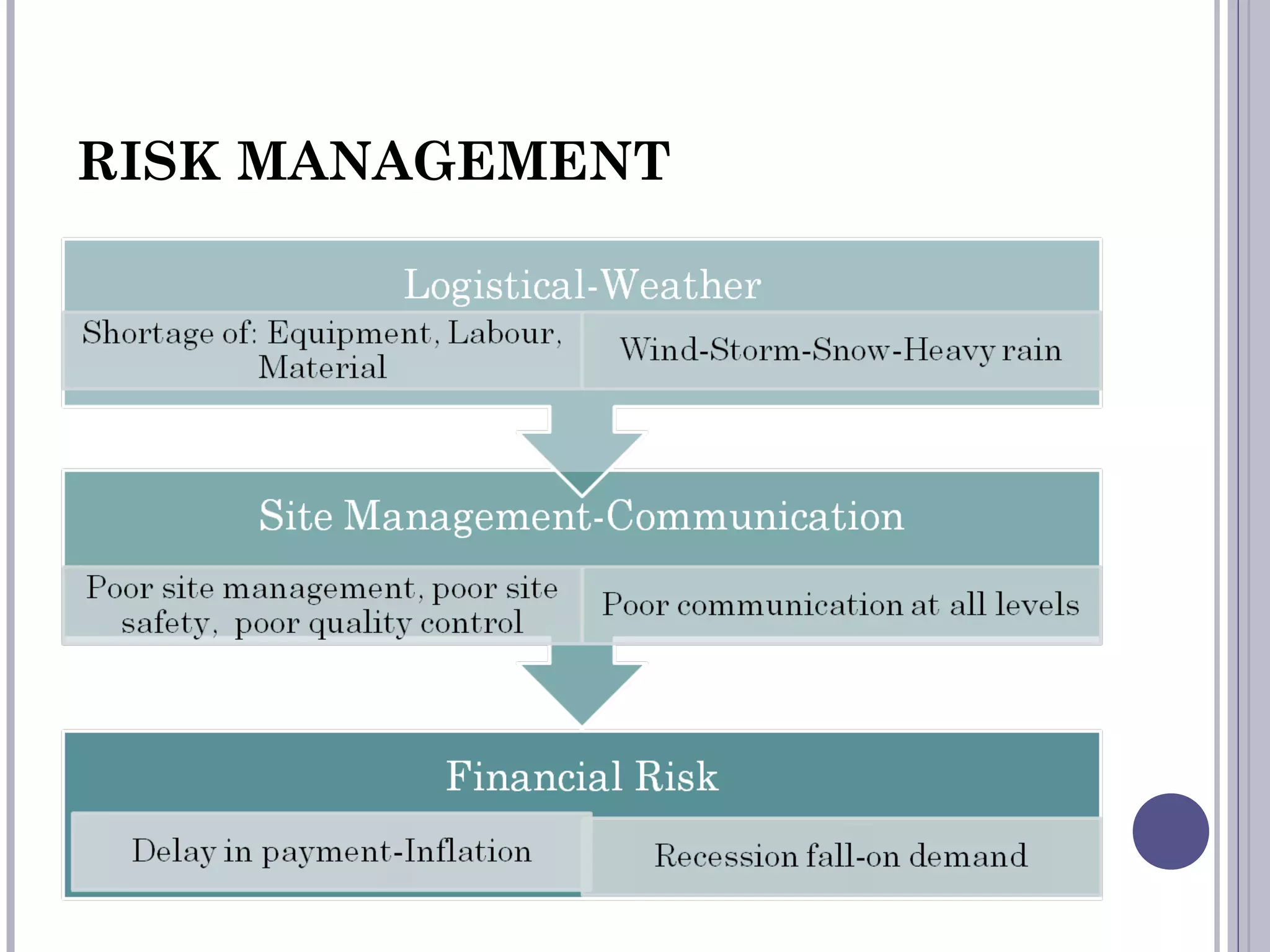

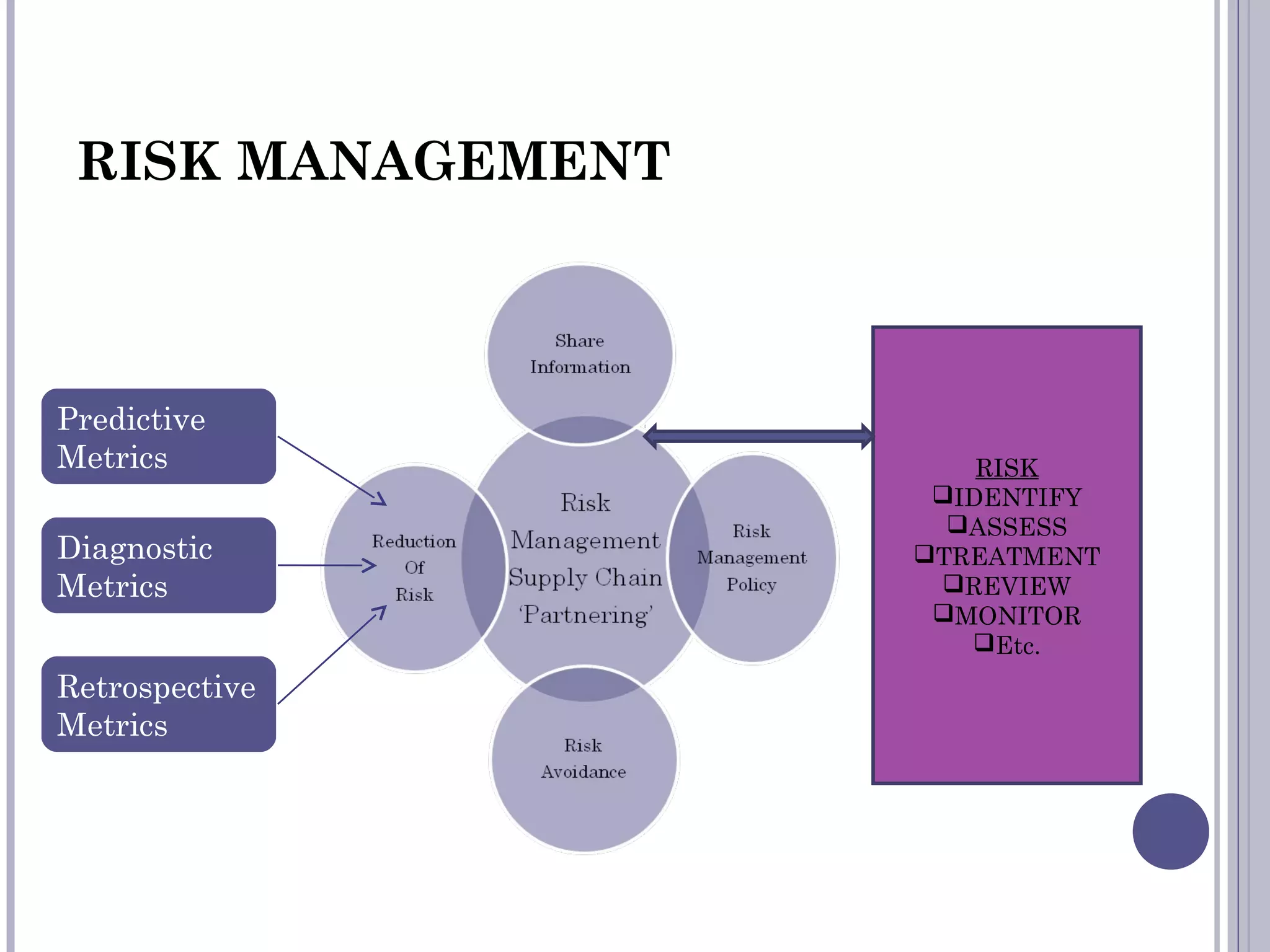

This document discusses risk management, cost control, and communication in construction projects. It describes how risk management involves identifying, assessing, and treating risks through various models and communication is key. It also explains that cost control is important for meeting project goals and involves establishing budgets, monitoring costs, and controlling changes. Effective risk management, cost control, and communication are important for construction project success.