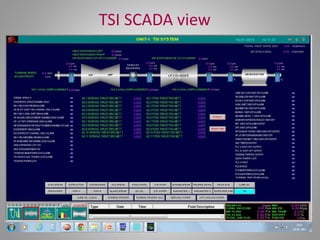

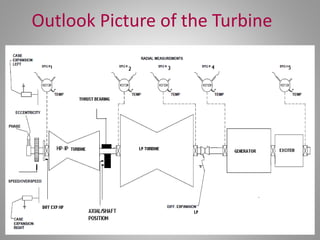

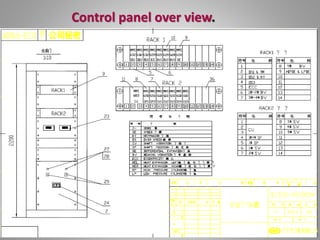

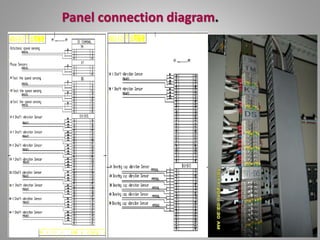

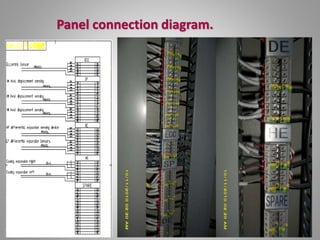

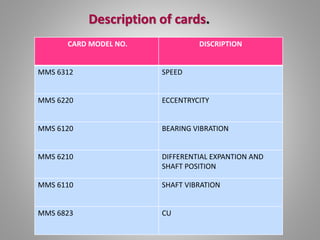

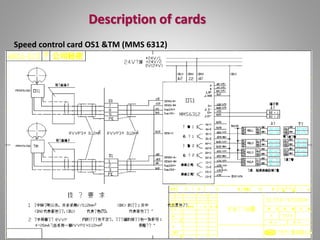

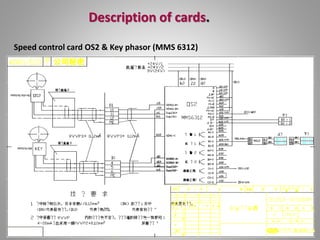

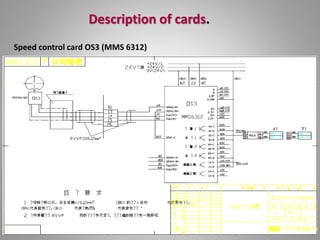

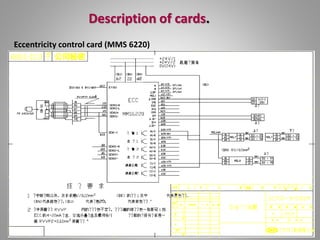

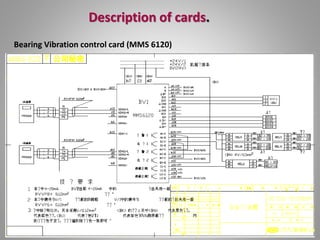

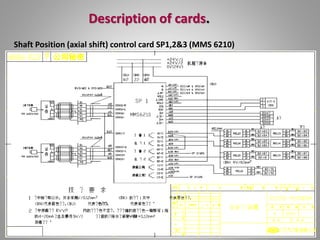

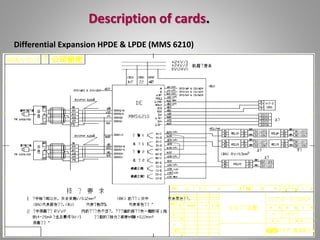

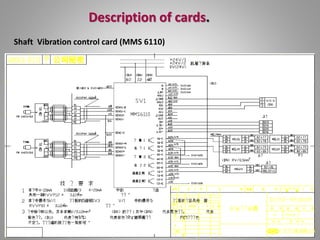

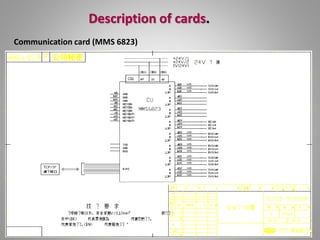

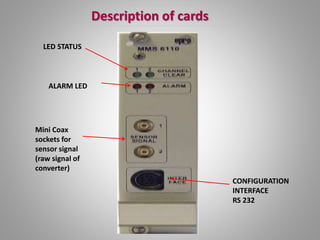

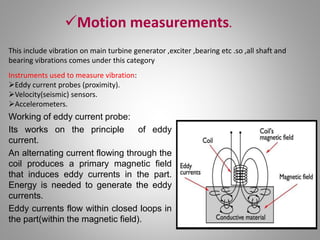

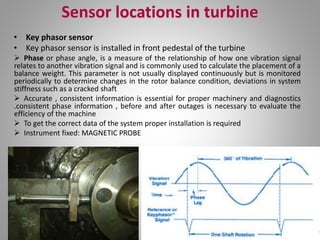

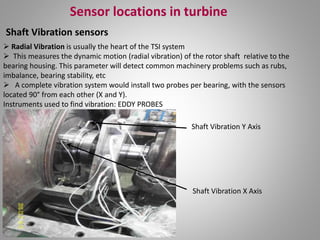

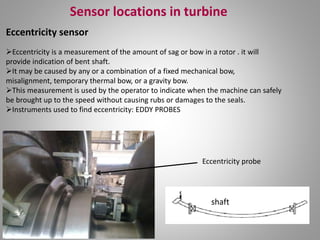

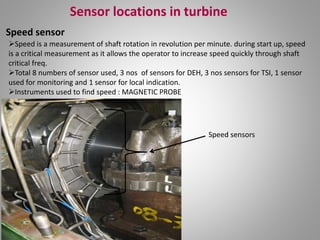

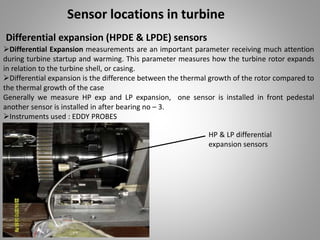

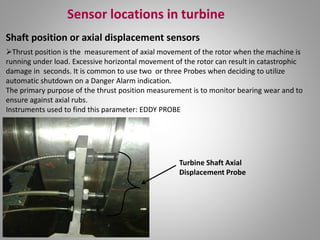

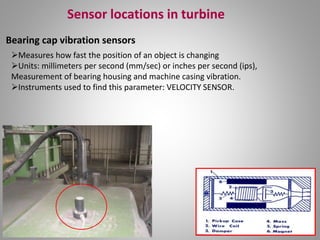

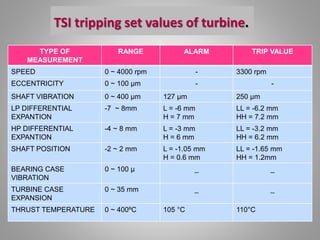

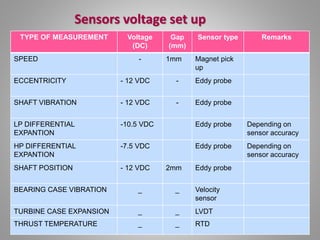

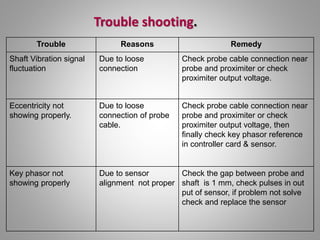

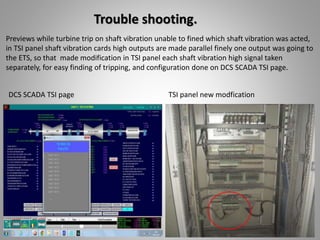

This document provides an overview of turbine supervisory instrumentation (TSI) systems. It discusses the benefits of TSI for monitoring critical turbine parameters, including reducing turbine roll times. It describes the various TSI measurement categories including motion, position, speed, and process measurements. Specific sensor locations and parameters measured are outlined, such as eccentricity, shaft position, speed, and differential expansion sensors. Turbine tripping set values and common troubleshooting issues are also covered.