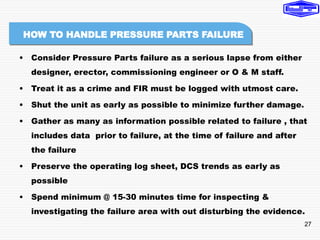

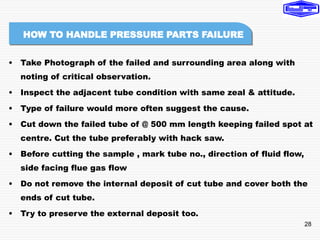

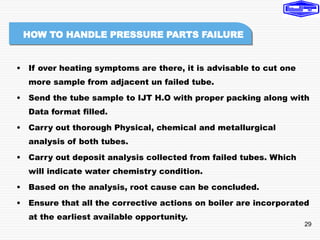

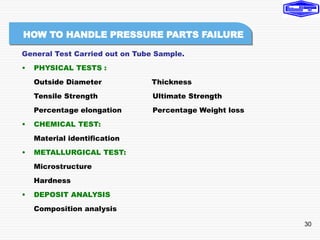

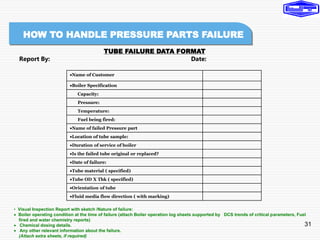

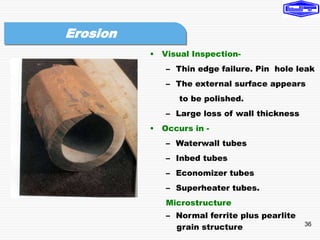

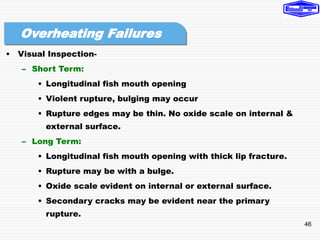

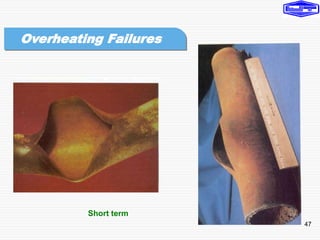

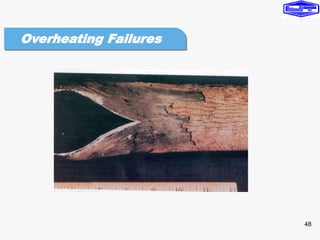

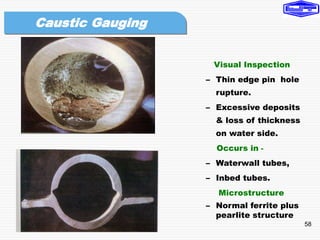

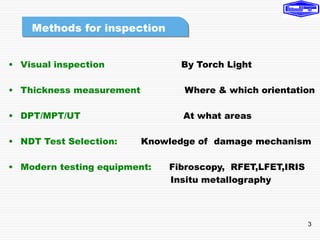

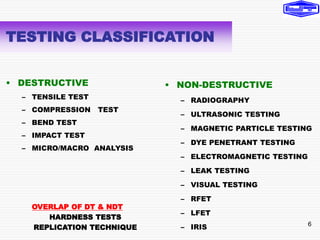

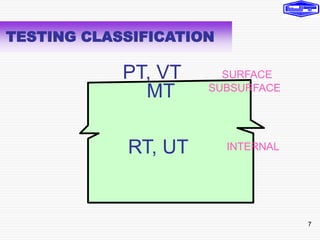

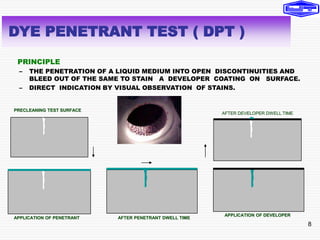

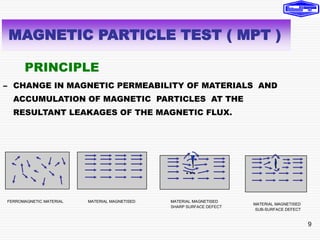

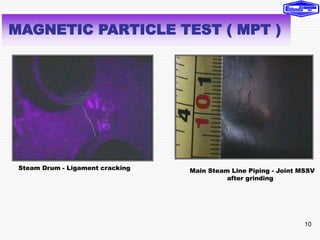

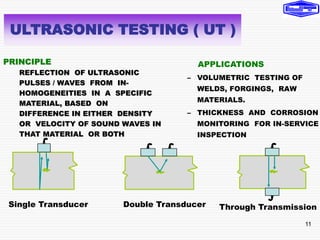

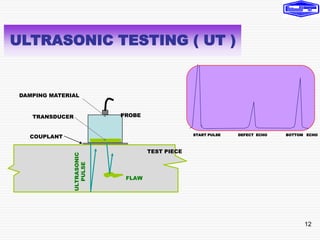

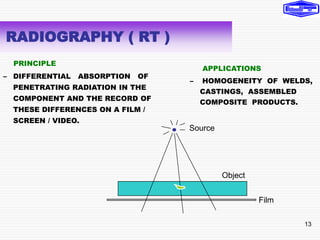

This presentation covers various inspection tests for pressure parts, including visual inspection, thickness measurement, non-destructive testing, and modern equipment. It discusses test classifications like destructive and non-destructive, as well as specific tests like dye penetrant, magnetic particle, ultrasonic, and radiography. The presentation also covers topics like failure analysis, corrosion measurement, and how to properly handle pressure part failures.

![19

TOD

T

Ts

Oxide Scale

t = 0.010” to 0.03”

0.001” scale - 20 F increase in TOD

T

OD

=

20

0

F

to

60

0

F

OXIDE SCALE MEASUREMNT

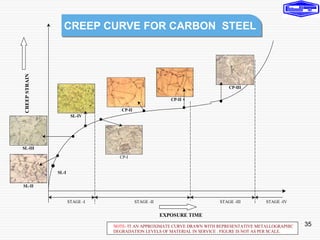

• Tube Temperatures > 900o F

• Failure prone by Creep Fatigue

• Oxide Scale formed (Fe2O3)

• Metal temperature increase 1-2o F

increases creep damage

Creep - Due to thermal

activation, materials can

slowly and continuously

deform even under constant

load (stress) and eventually

fail.

[The time dependent,

thermally assisted

deformation of components

under load (stress)]

Stress Rupture

Corrosion Assisted

Erosion Assisted](https://image.slidesharecdn.com/06-230731070801-97739cce/85/06-Tube-failures-Testing-Equipment-ppt-19-320.jpg)