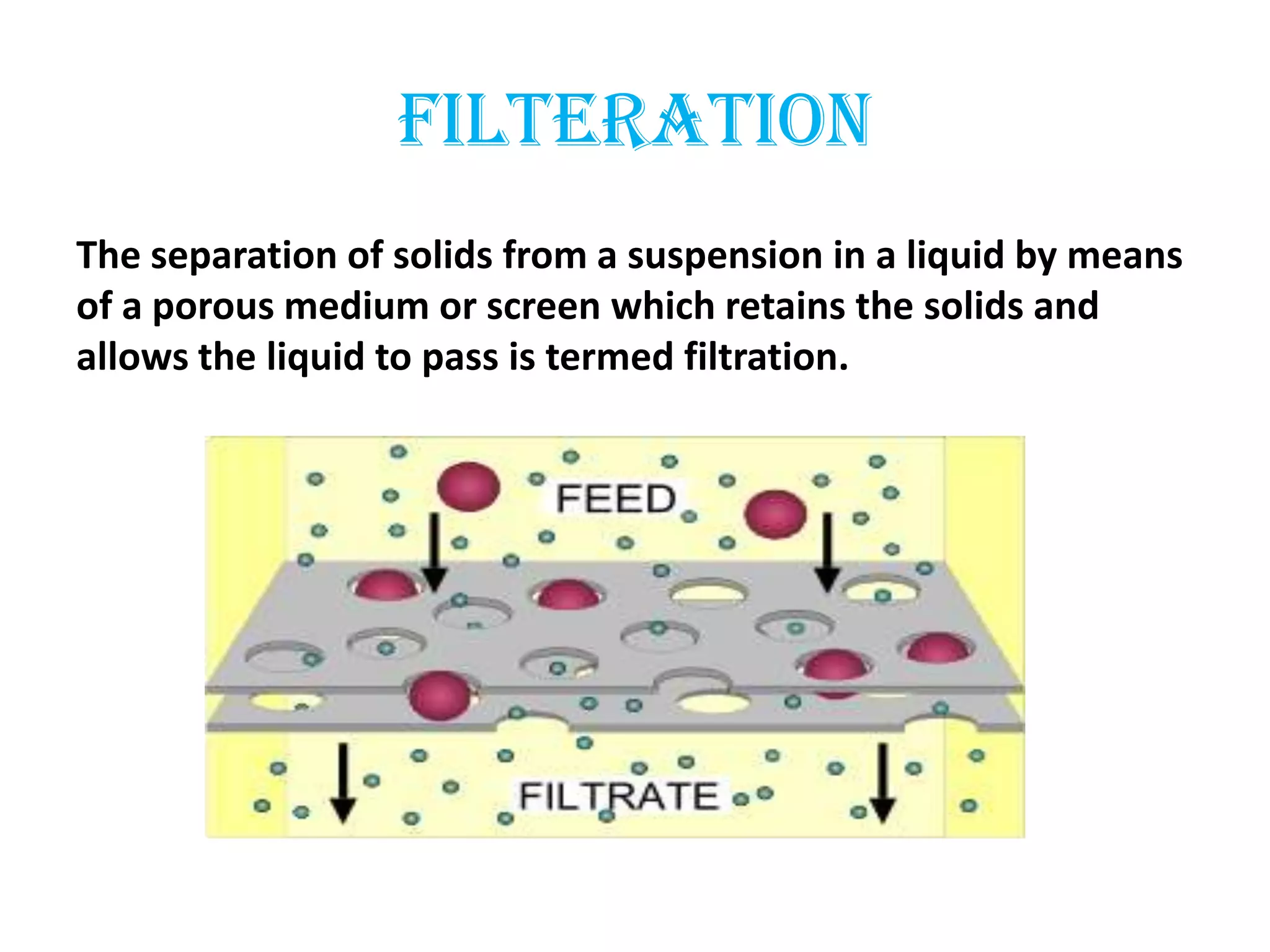

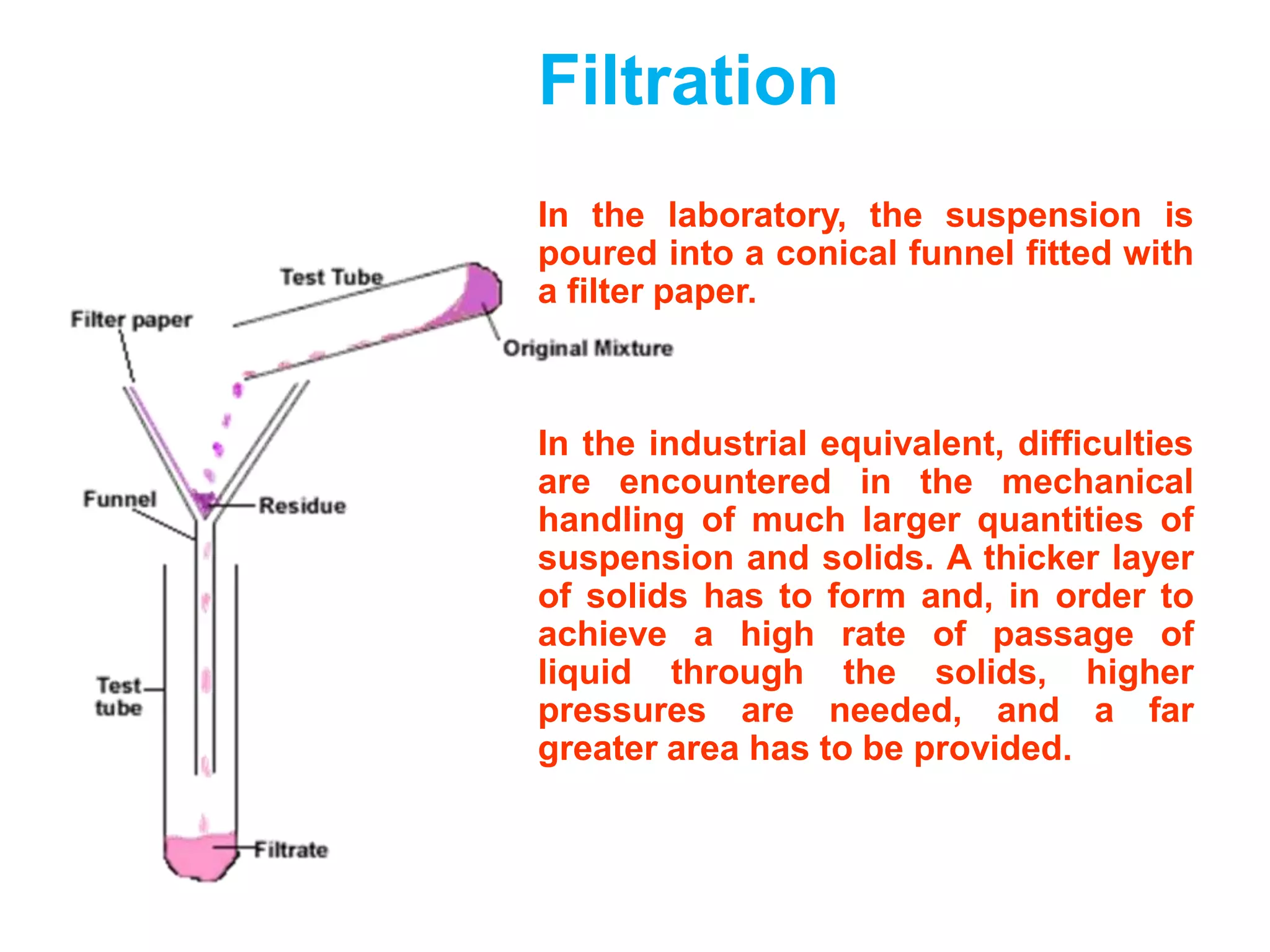

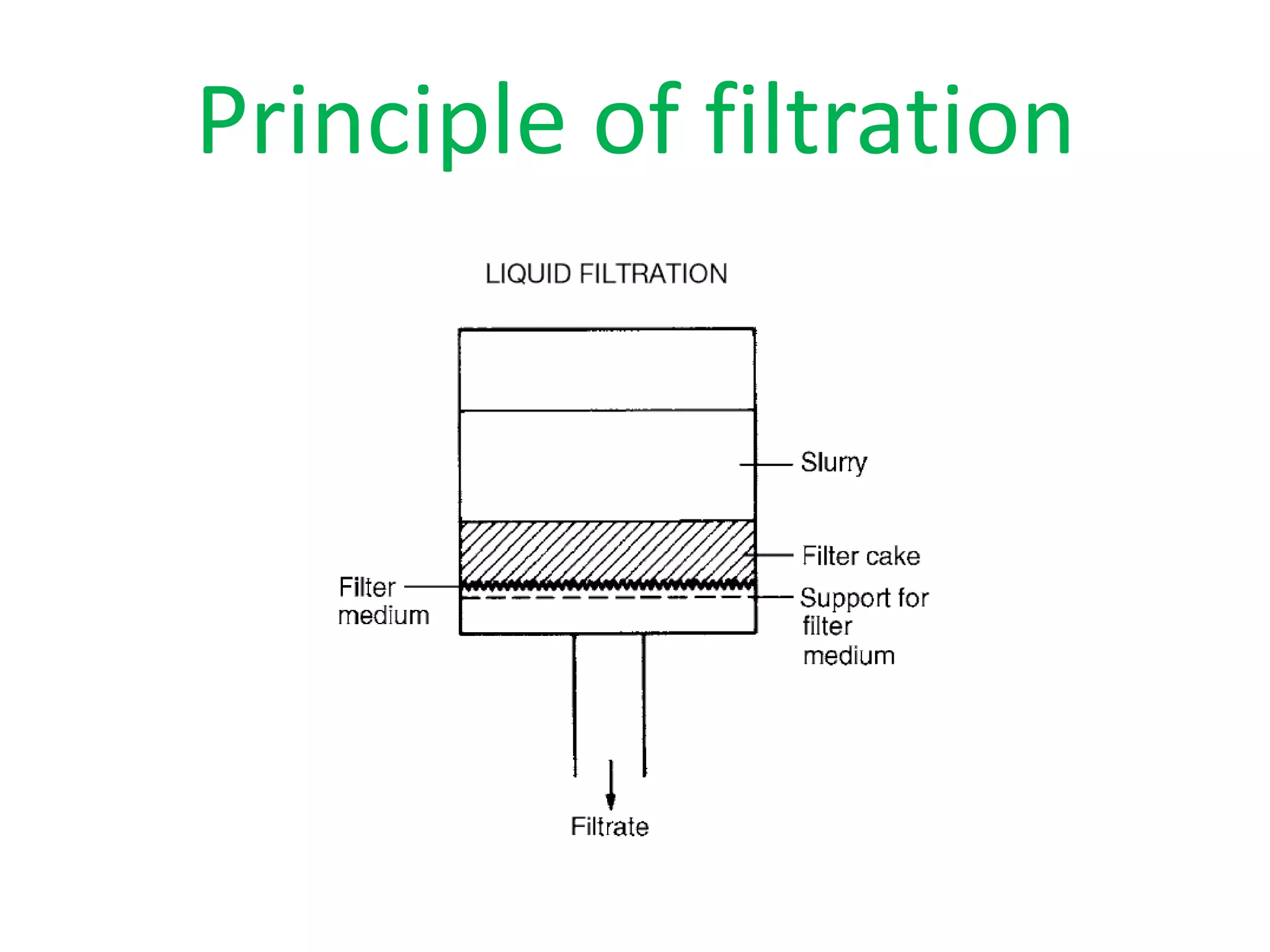

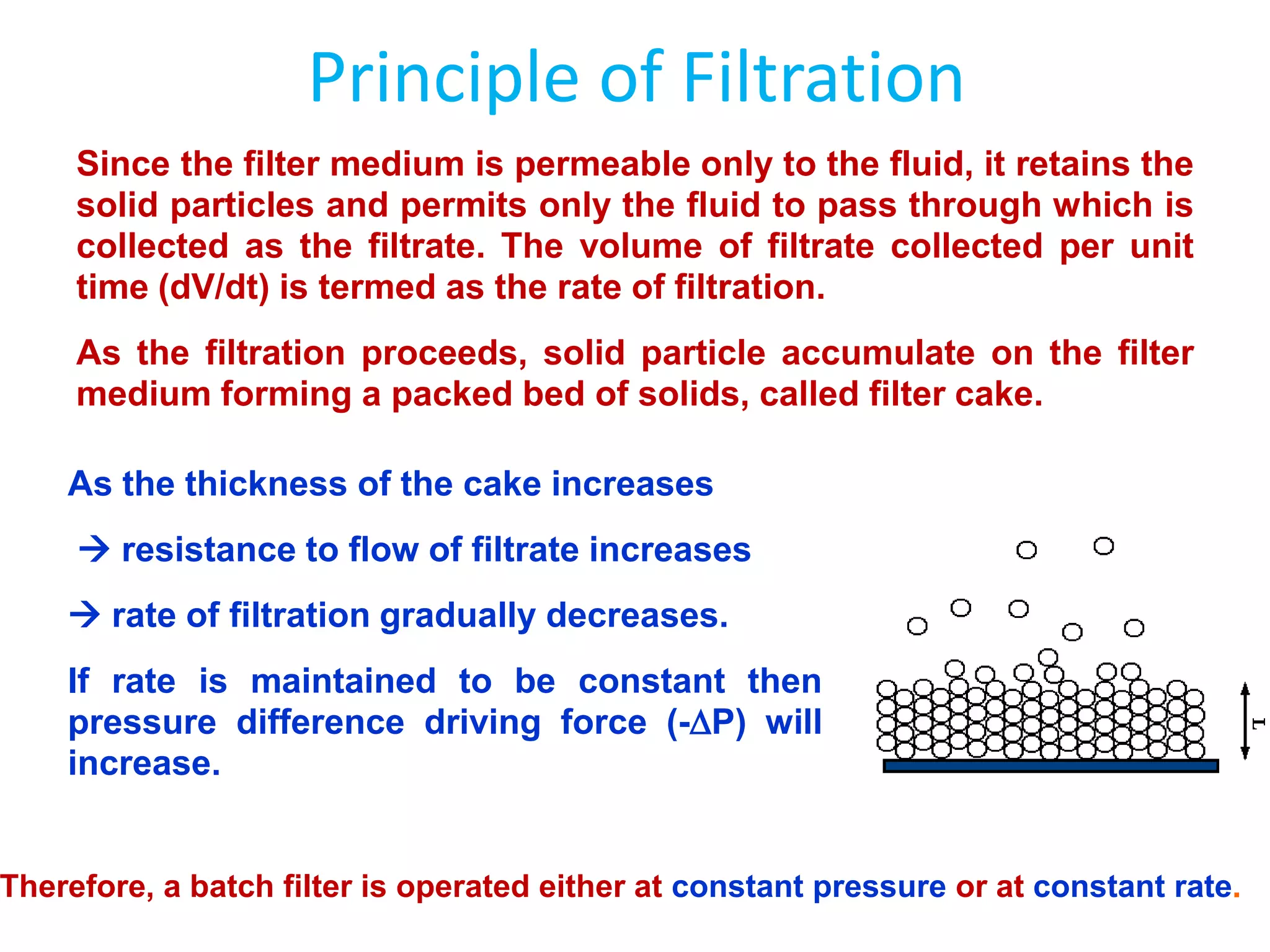

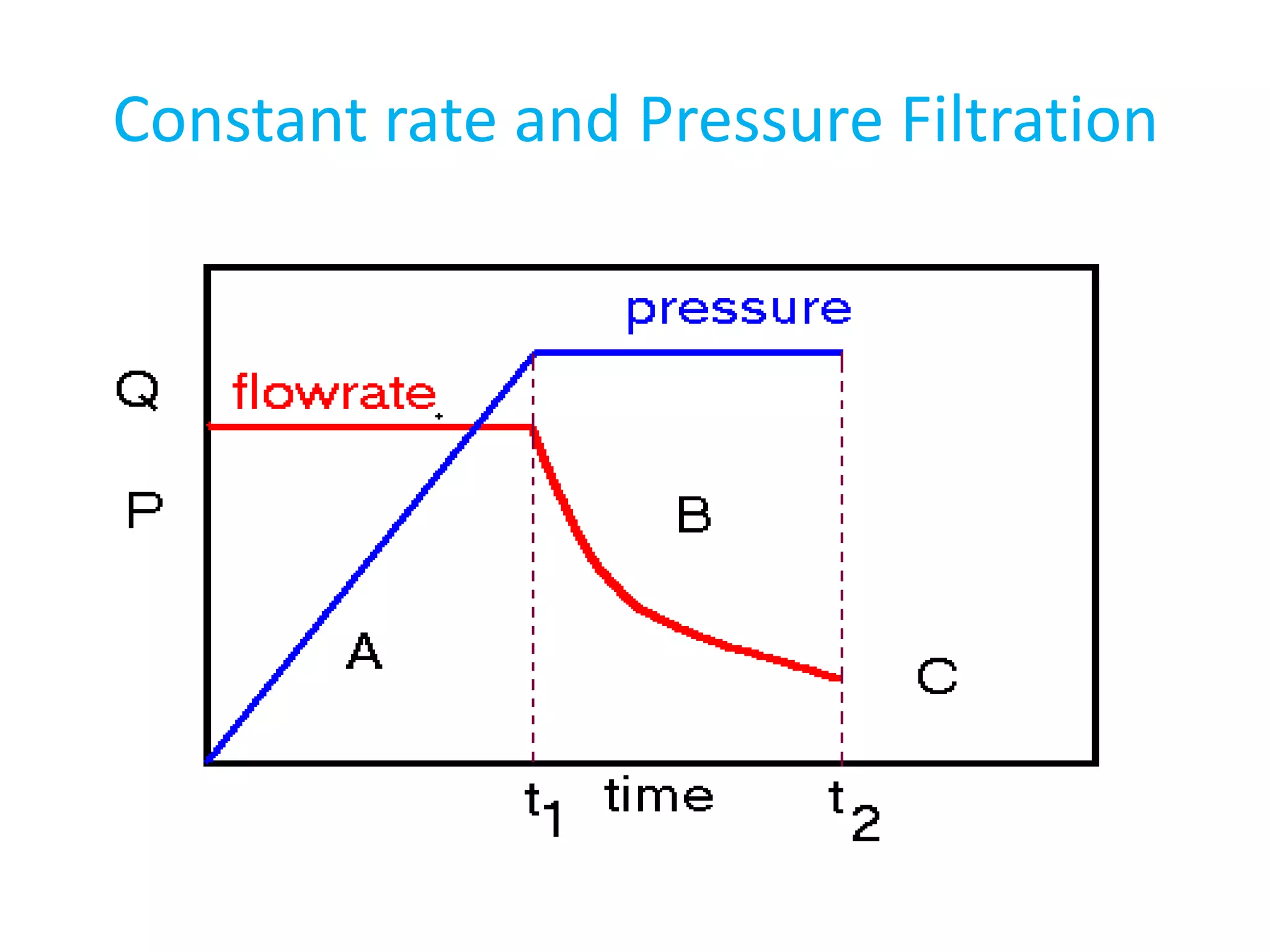

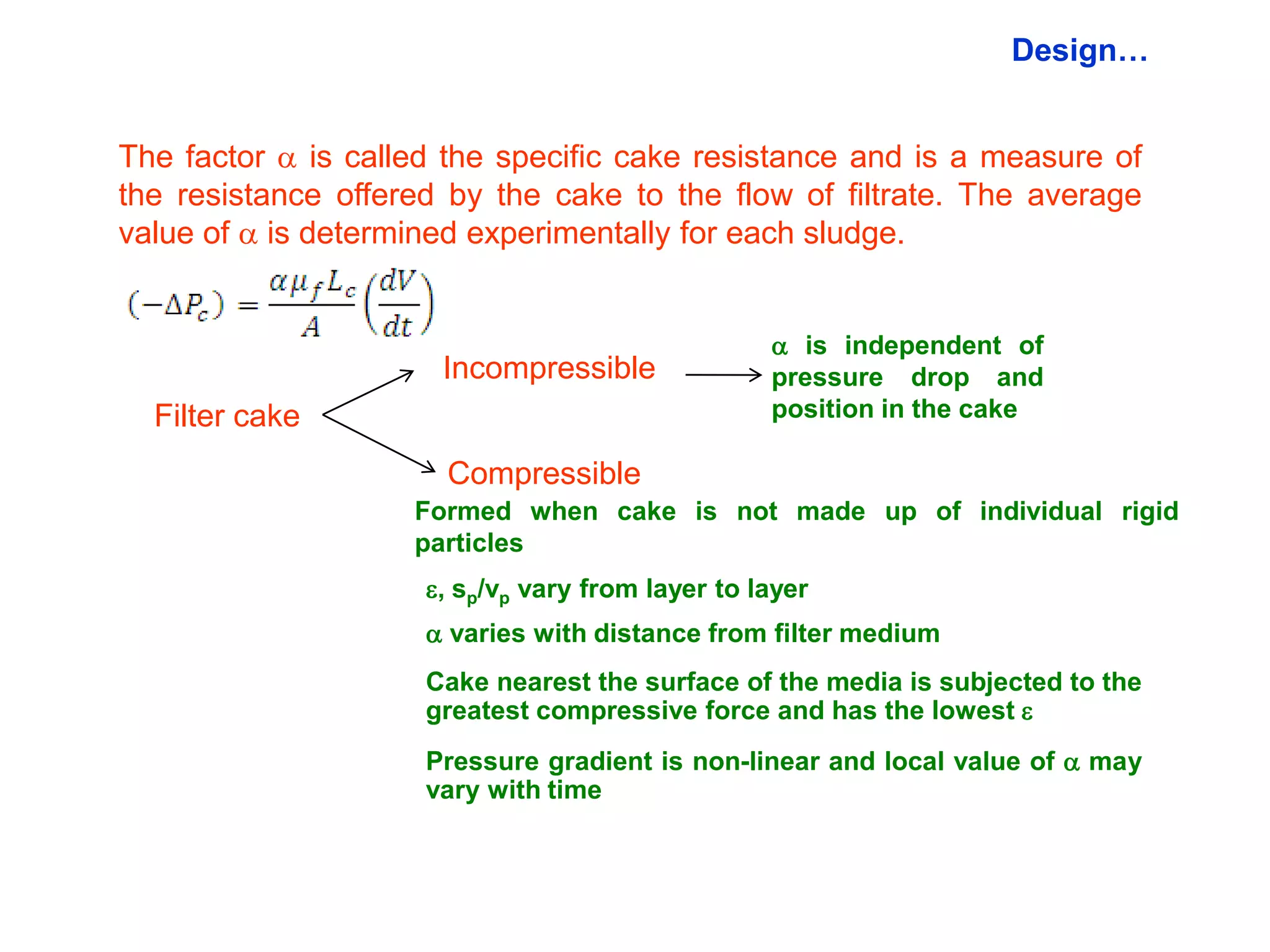

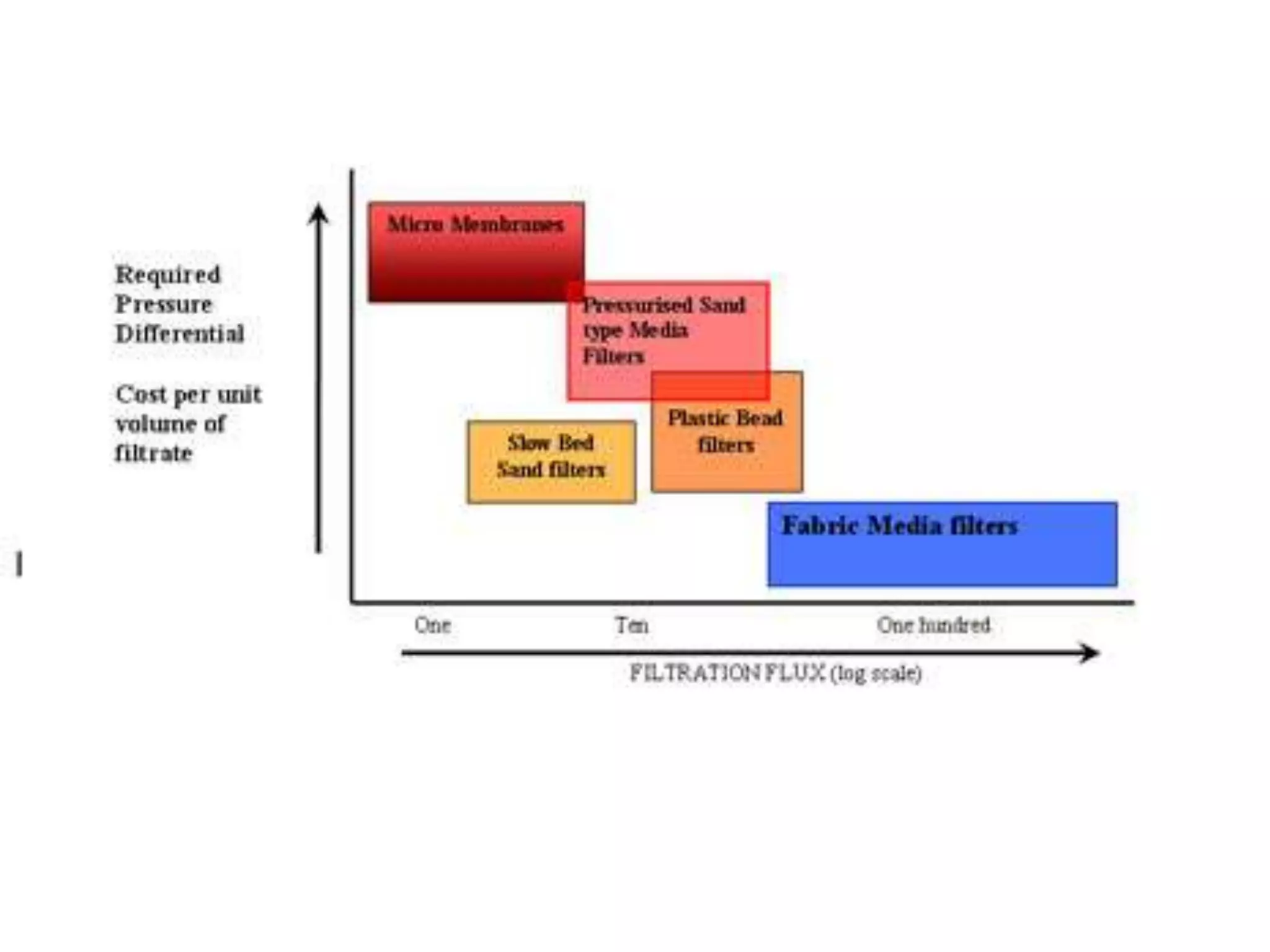

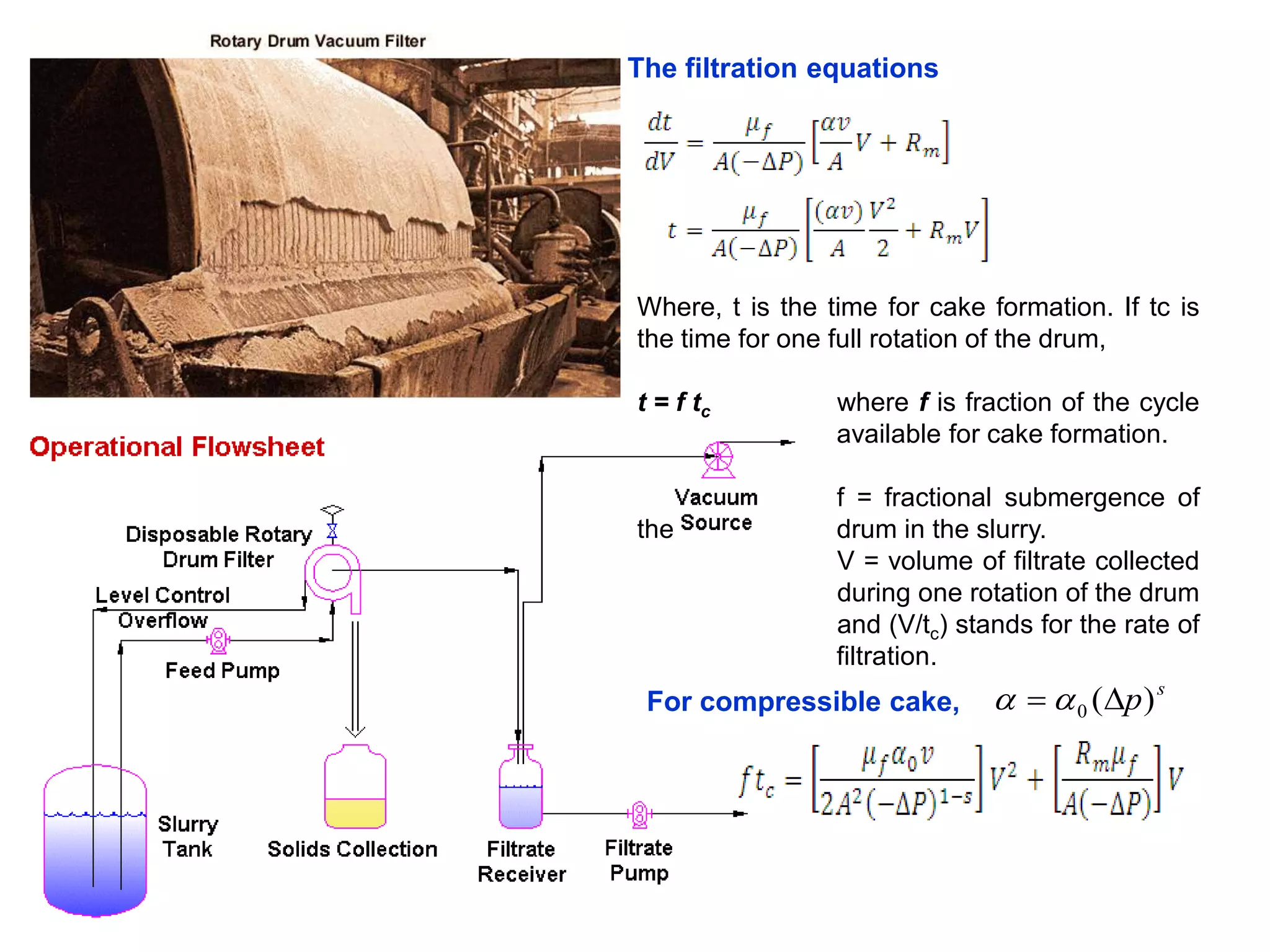

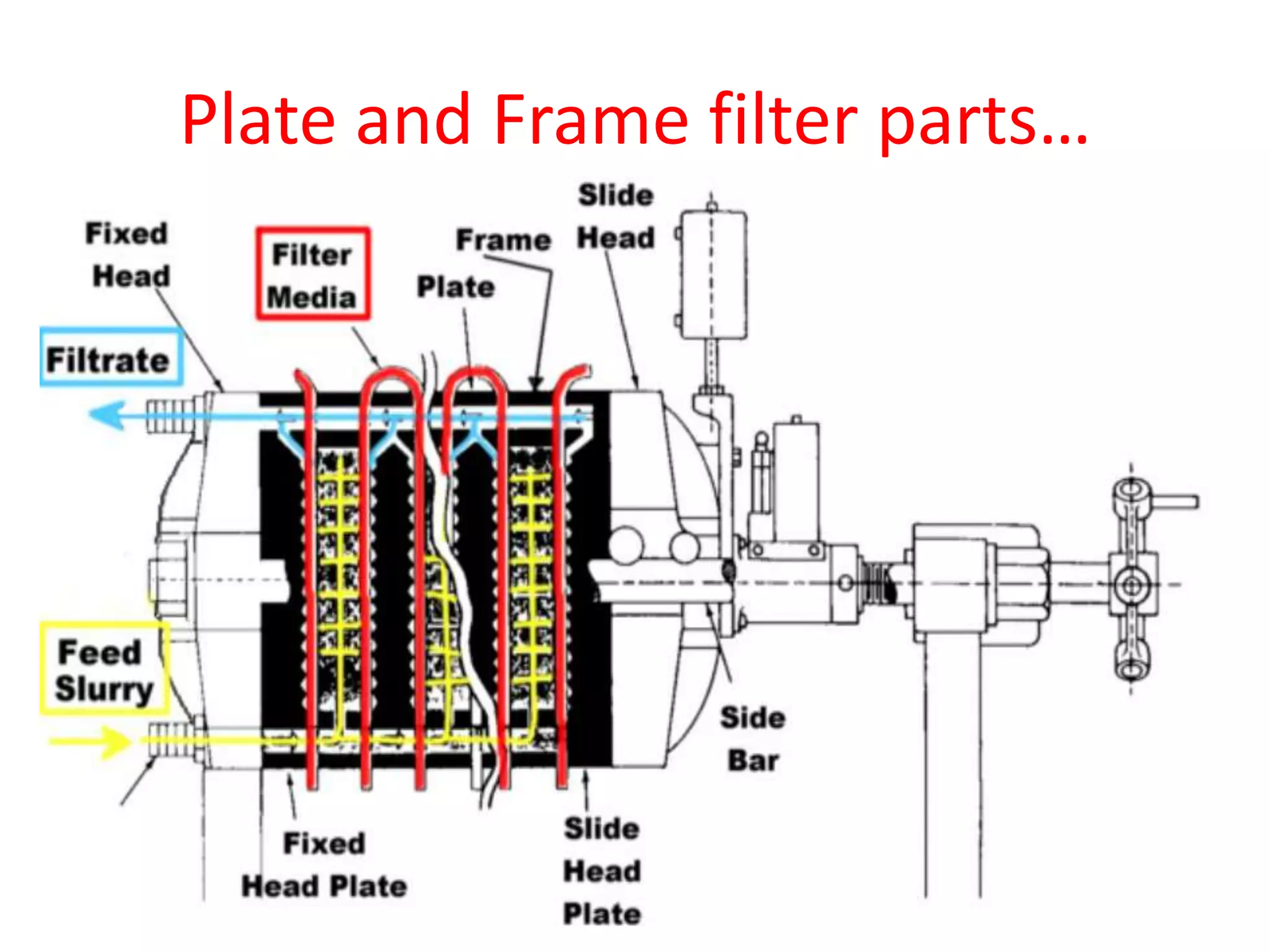

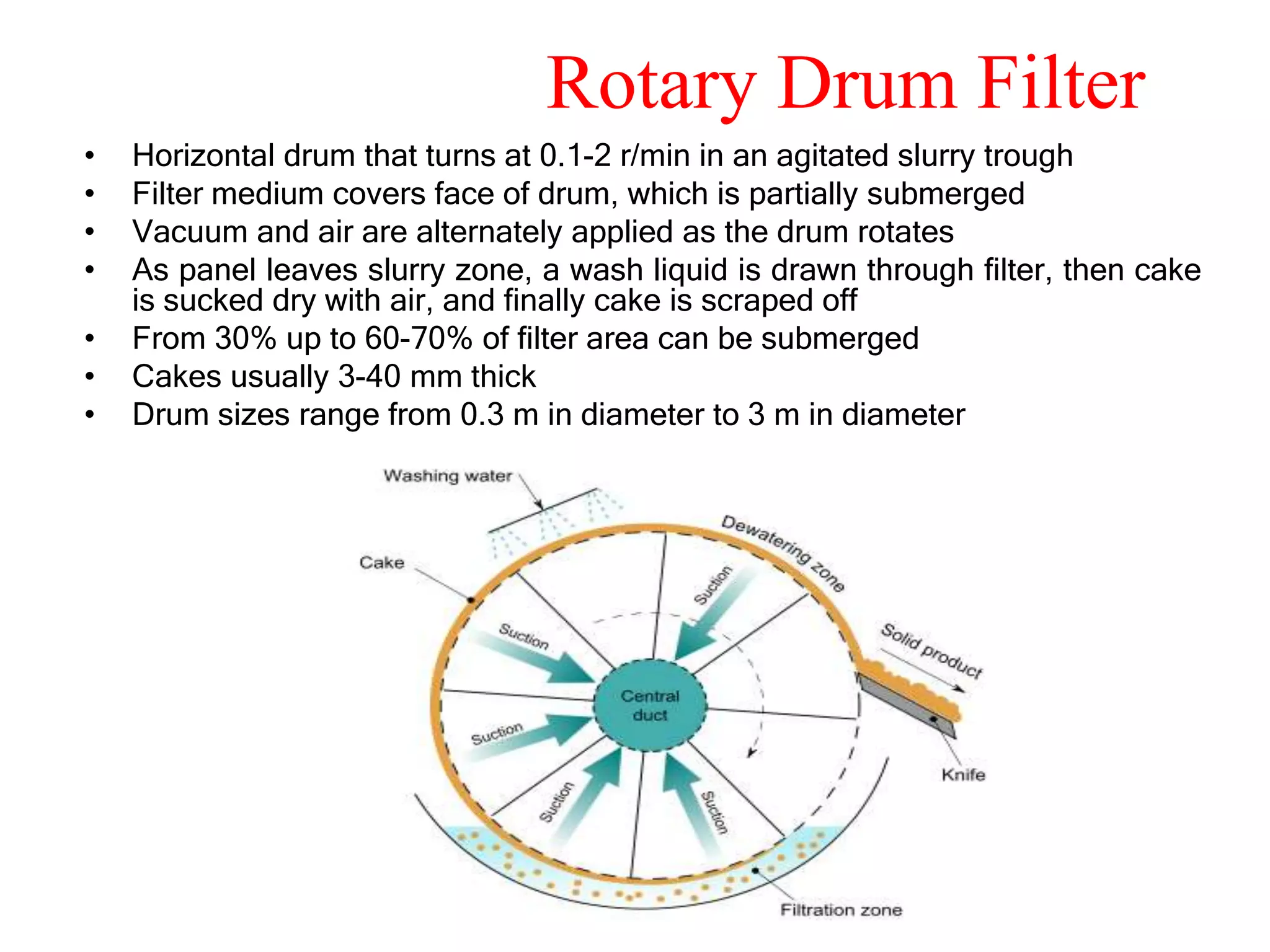

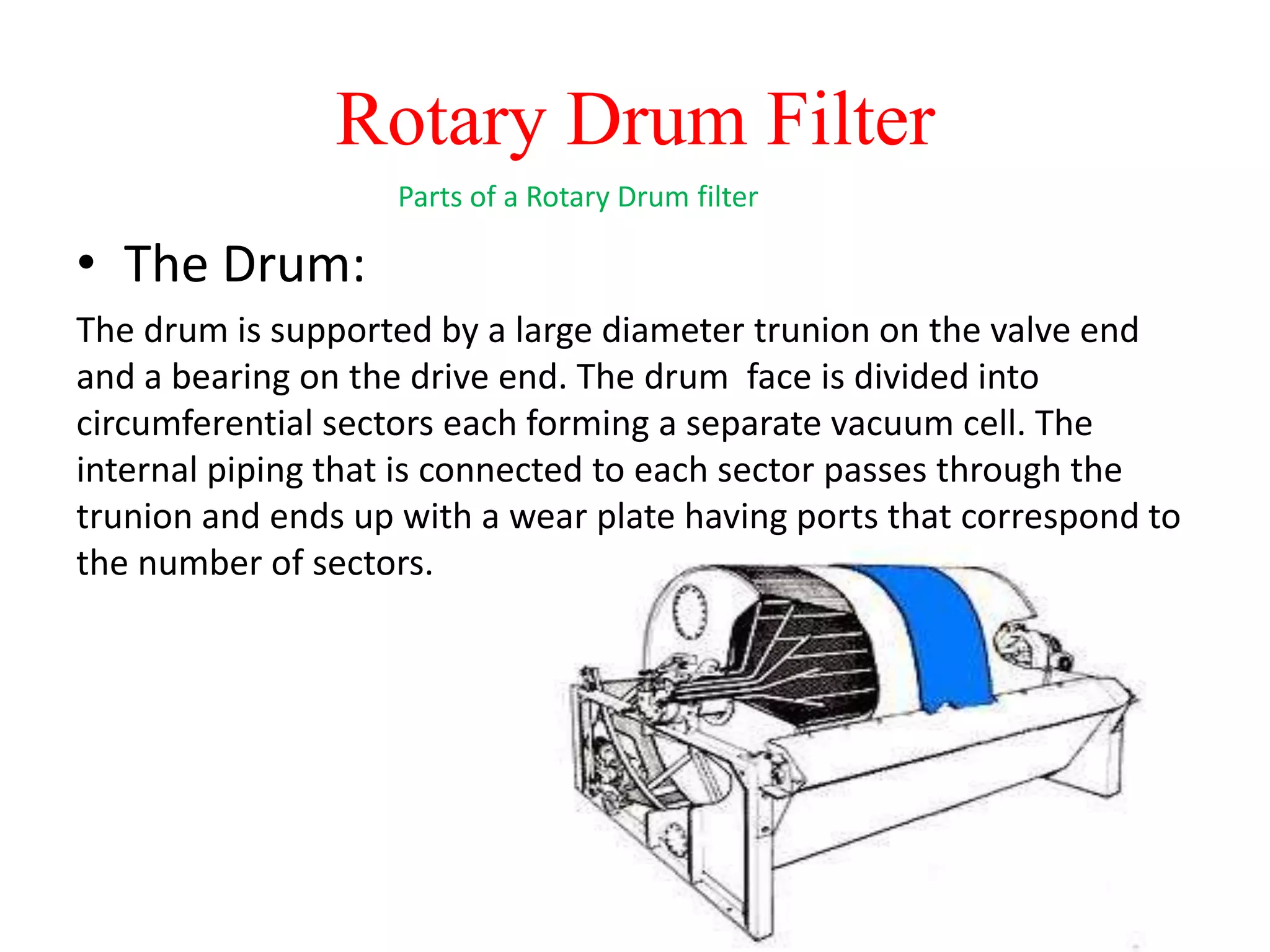

This document discusses various types of filtration processes. It begins by defining filtration as the separation of solids from a liquid suspension using a porous medium. It then describes different filter media types, including cake filters, clarifying filters, cross-flow filters, and ultrafilters. The document provides equations for calculating pressure drop and flow rate during batch and continuous filtration. It also discusses specific cases like constant pressure/rate filtration of compressible vs incompressible cakes. Finally, it describes common industrial filtration equipment like plate and frame filter presses, rotary drum filters, and shell and leaf filters.

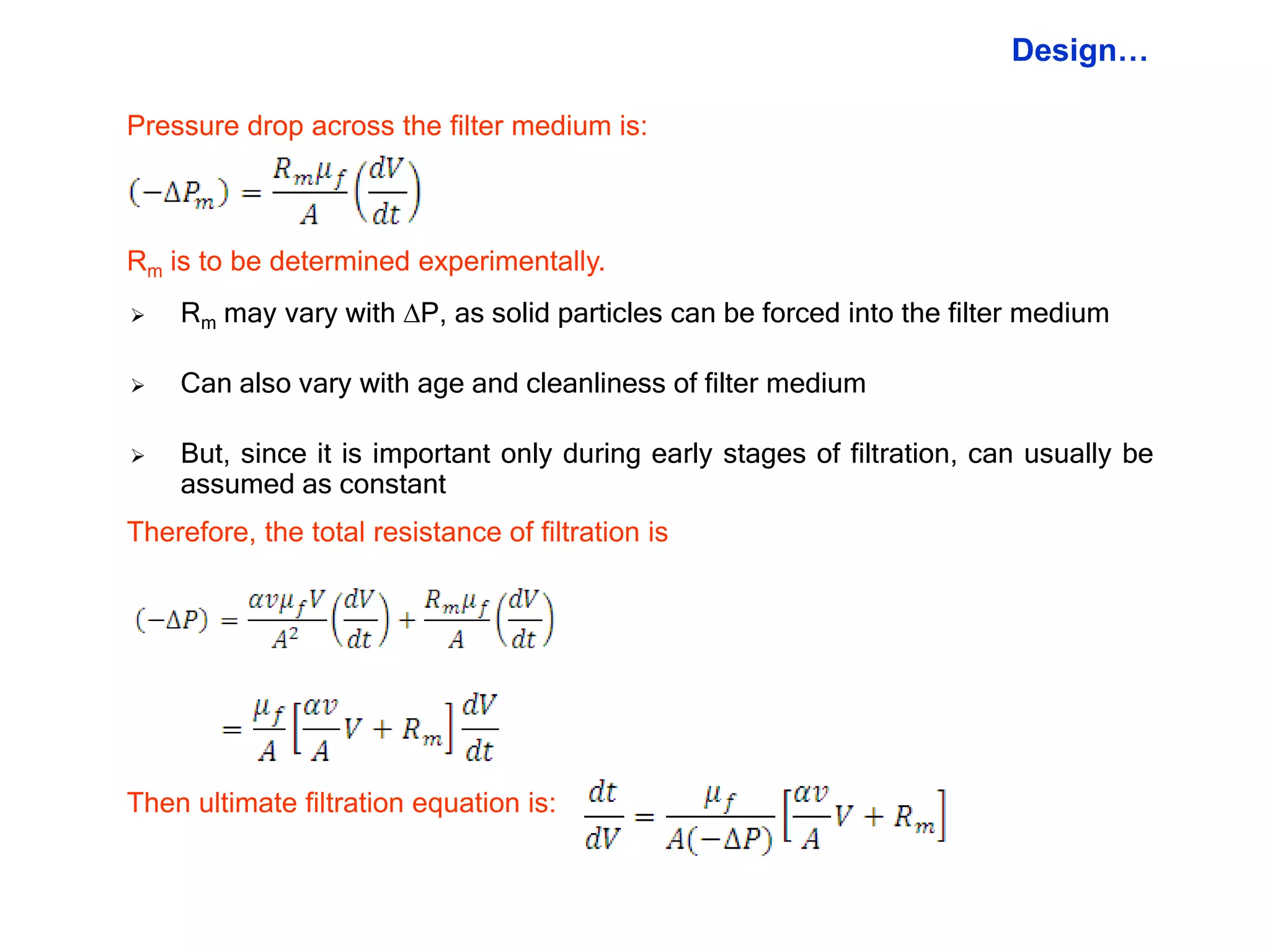

![The Horizontal belt Filter

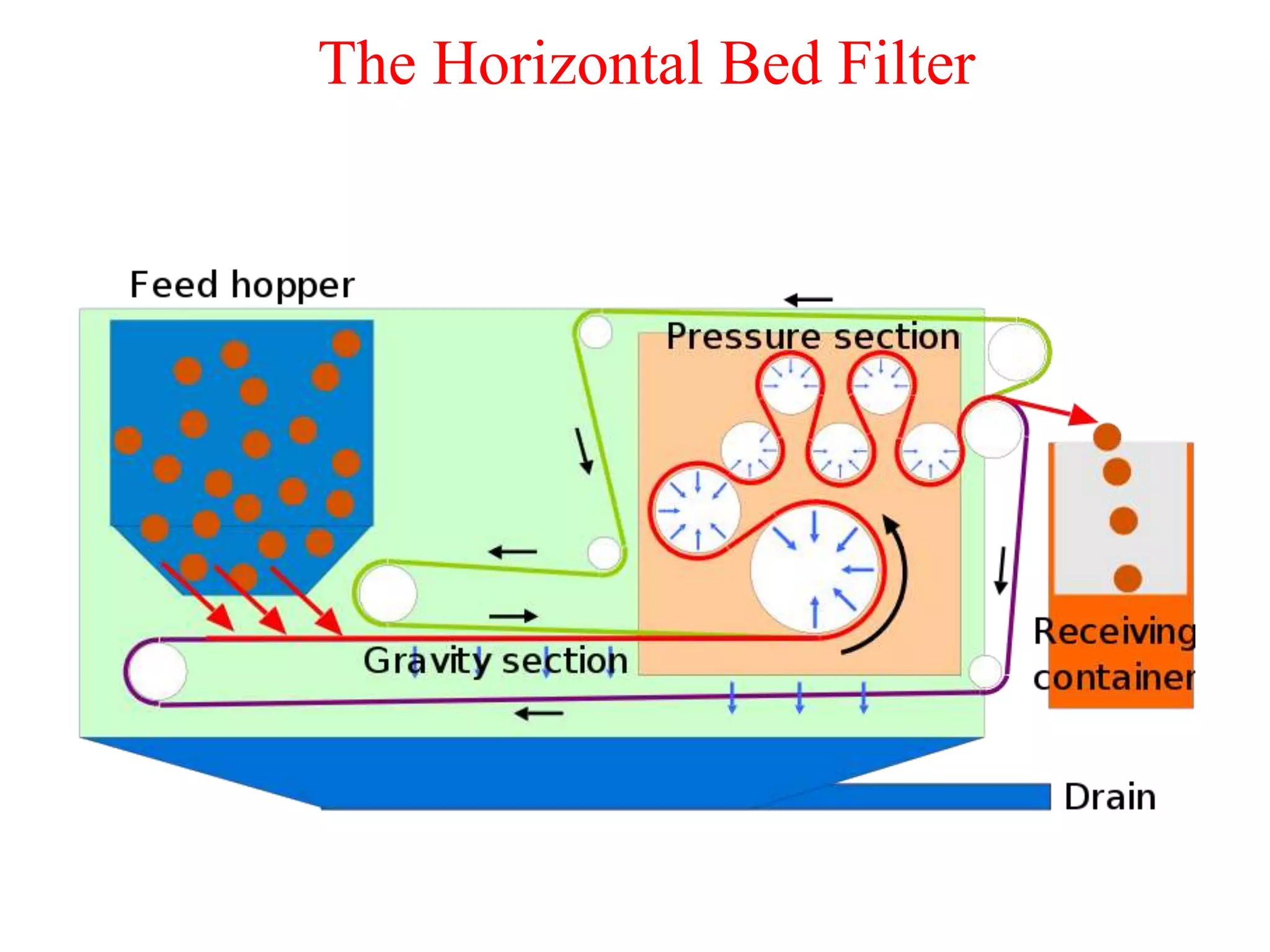

Operation:

The feed sludge to be dewatered is introduced from a hopper between two

filter cloths (supported by perforated belts) which pass through a convoluted

arrangement of rollers. As the belts are fed through the rollers, water is

squeezed out of the sludge. When the belts pass through the final pair of

rollers in the process, the filter cloths are separated and the filter cake is

scraped off into a suitable container.[1] A belt filter is generally used in

phosphate fertiliser plants to separate the solid from slurry. It comprises

washing to different zone to minimise the product losses. Belt filters use a

vacuum system to minimise off gas and effluent during operations. It has

applications in many other areas of industry.](https://image.slidesharecdn.com/filtration-130307093647-phpapp02/75/Filtration-53-2048.jpg)

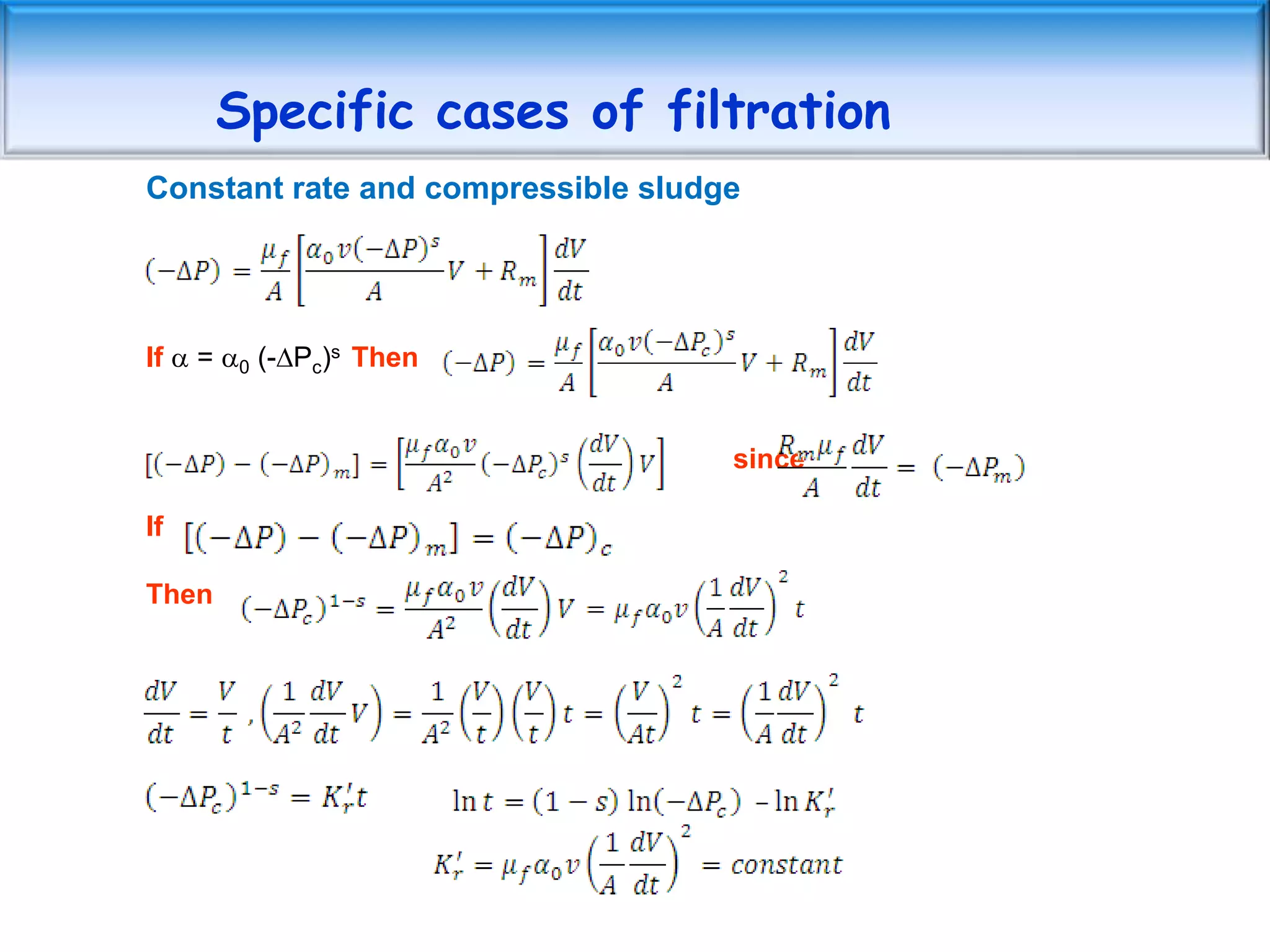

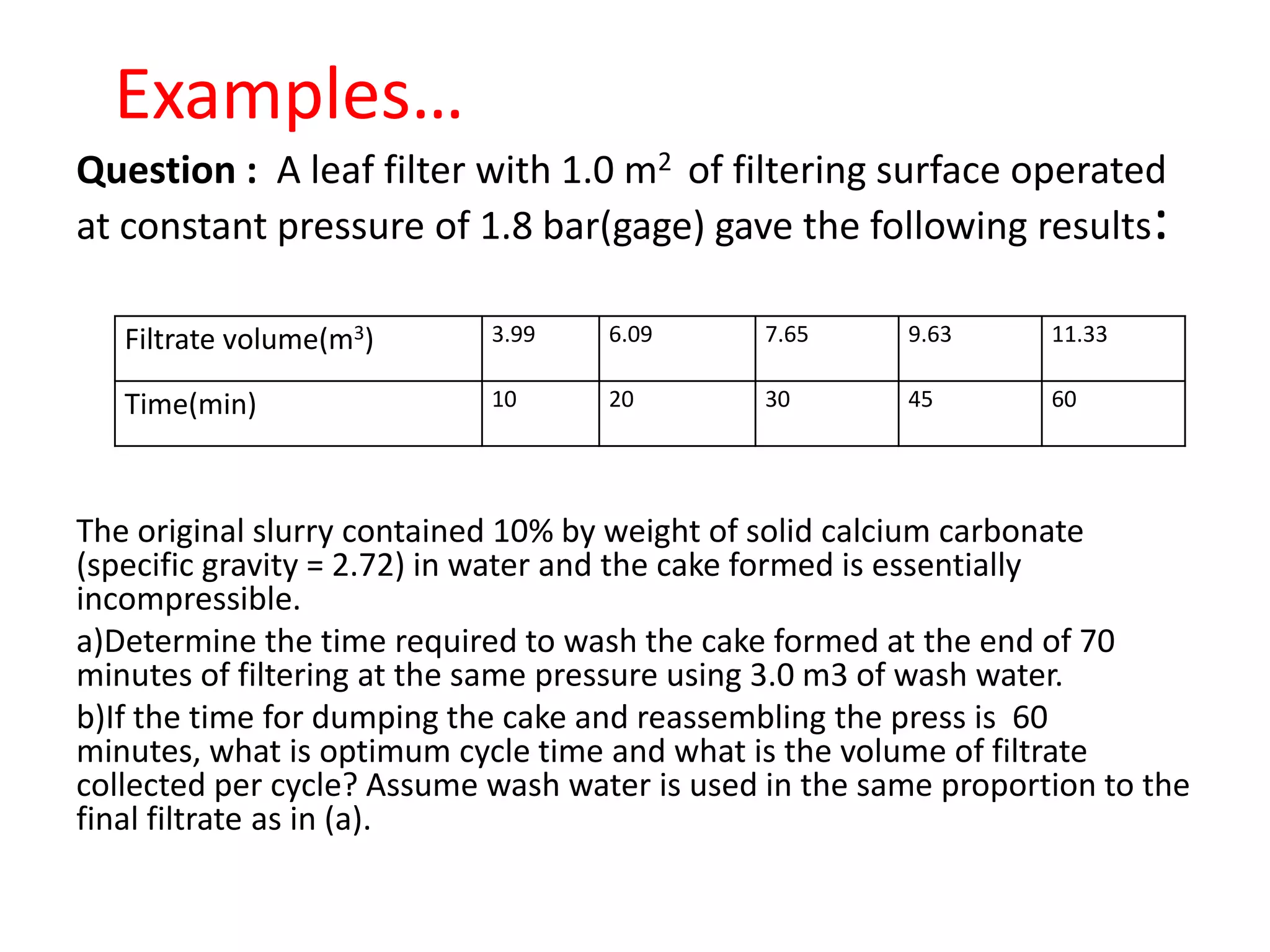

![Solution:

%input

fs=1;%filtering surface=1 m^3

p=1.8; %constant pressure= 1.8 bar

x=0.1; % weight % of calcium cabonate

sp=2.72; % specific gravity =2.72

tf=70; %70 mins of filtering

tf=tf*60;

vw=3; %volume of wash water m^3

tetc=3600;

t=[10,20,30,45,60];%t time in mins

fv=[3.99,6.09,7.65,9.63,11.33]; %fv= filterate volume (m^3)

n=5;% n=no. of values of filterate volume

dt=size(n-1);

dfv=size(n-1);

dtf=size(n-1);](https://image.slidesharecdn.com/filtration-130307093647-phpapp02/75/Filtration-84-2048.jpg)