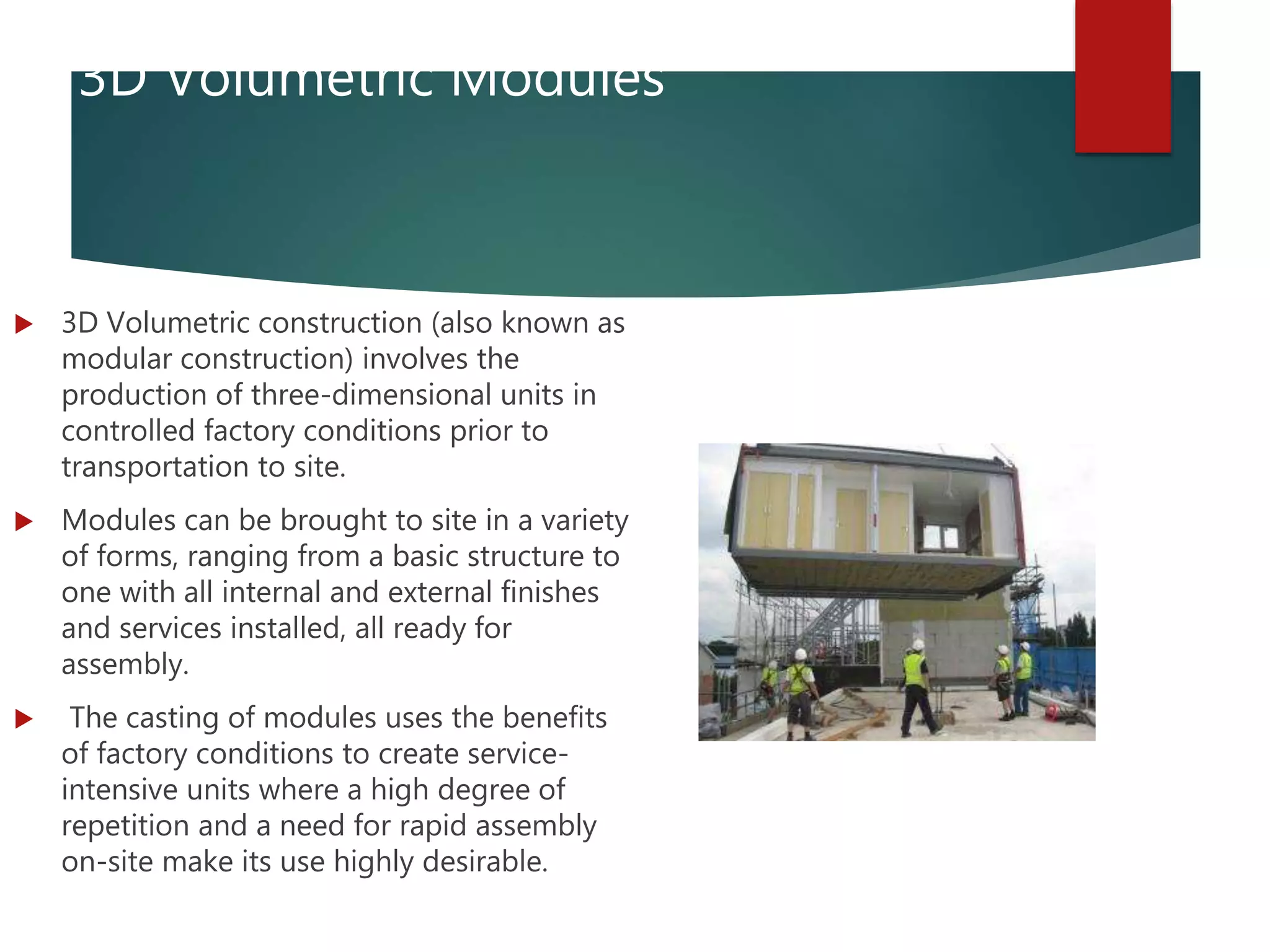

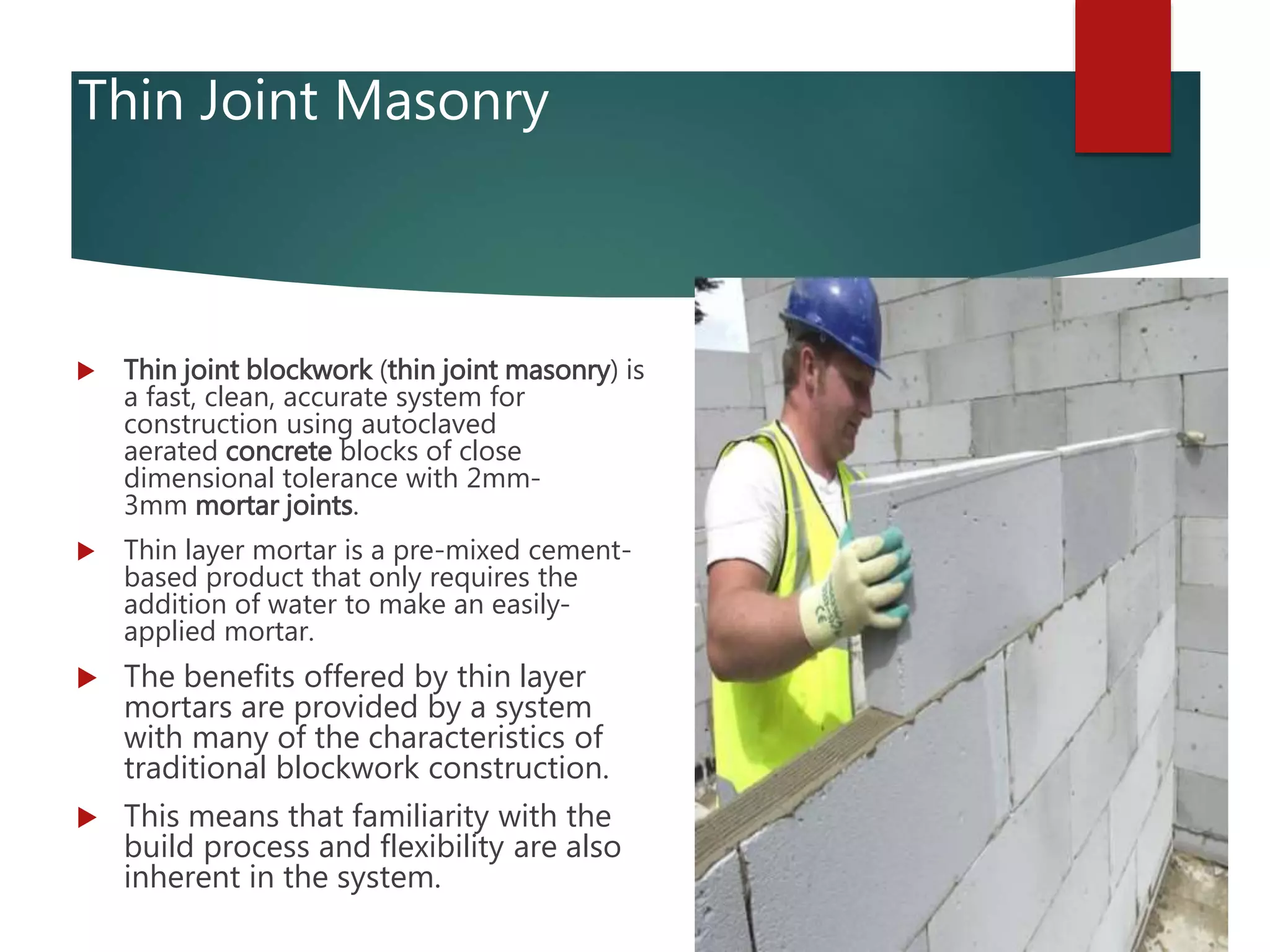

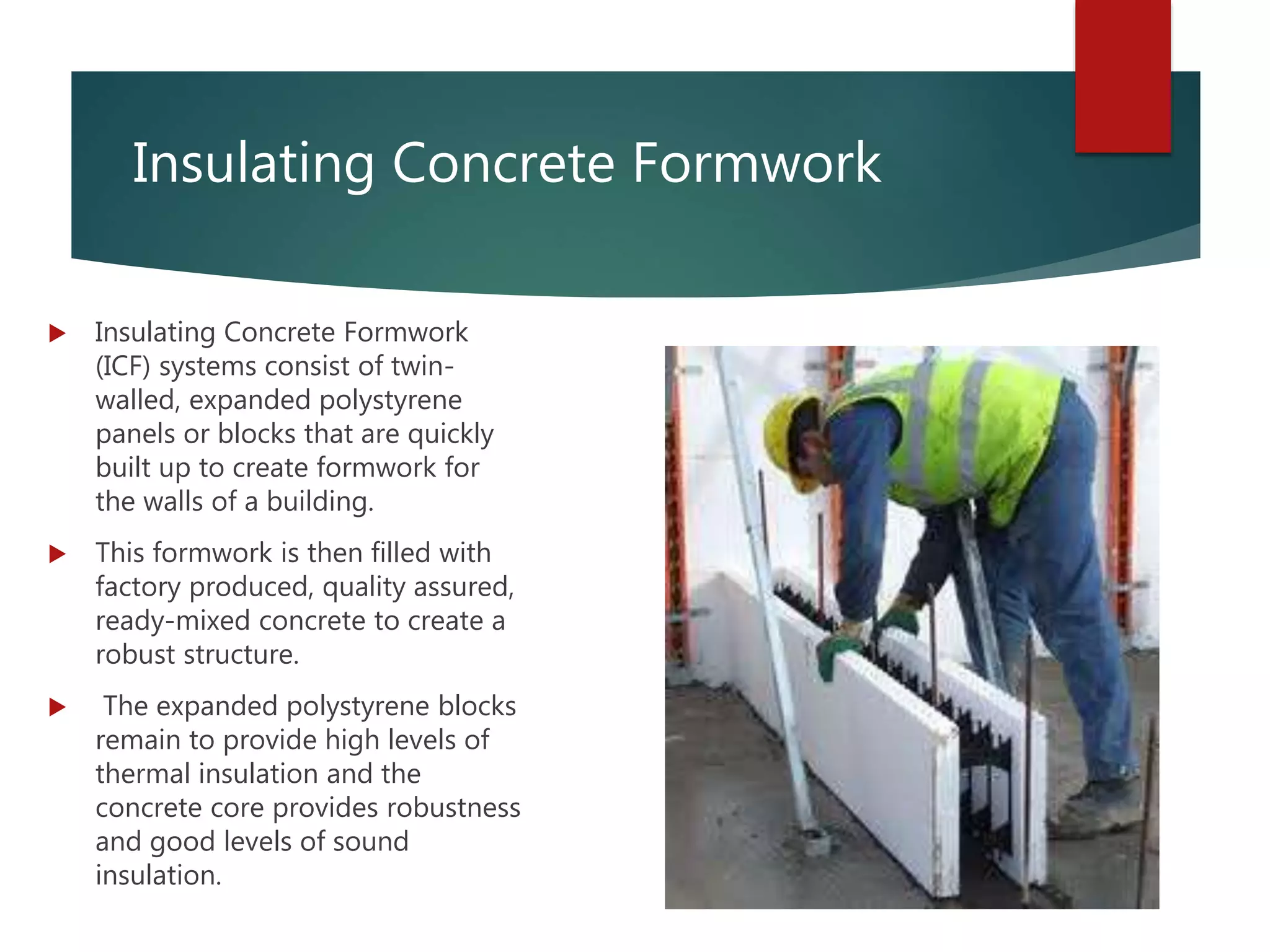

The document discusses various modern construction technologies including concrete walls and floors, precast cladding panels, 3D volumetric modules, twin wall technology, flat slabs, thin joint masonry, insulating concrete formwork, and precast concrete foundations. These technologies aim to reduce costs and construction time while improving quality, through the use of prefabricated concrete elements constructed in a controlled factory environment and assembled on site.