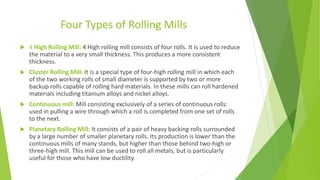

The document discusses various types of rolling mills used in the steel industry for reducing metal width and increasing hardness. It details four specific types: 4 high rolling mills, cluster rolling mills, continuous mills, and planetary rolling mills, each with unique characteristics and applications. These processes are energy-efficient, producing uniform products of higher quality.