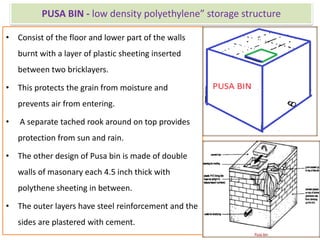

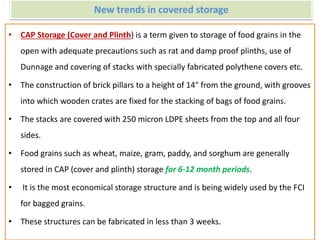

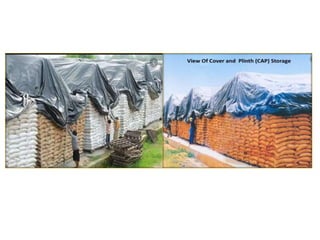

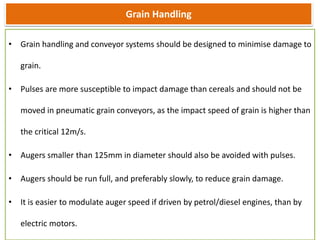

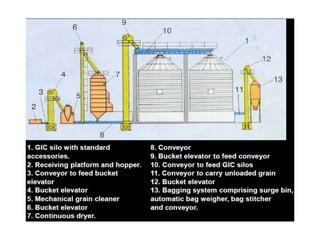

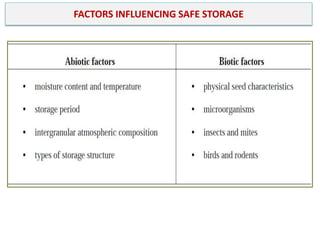

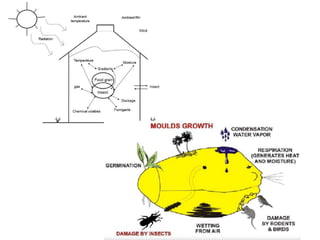

This document discusses recent advances in grain storage and handling. It notes that grains are a major global food staple and that improper post-harvest handling in India results in losses of 12-16 million metric tons annually. Modern storage structures like silos, warehouses and hermetic bags have been introduced to better preserve grain quality and prevent losses during storage and transport. These structures aim to protect grains from moisture, pests and temperature fluctuations for longer storage periods. Proper cleaning, drying, fumigation and pest control are also important aspects of maintaining grain quality in storage facilities.