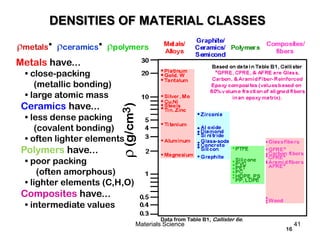

This document provides an overview of materials science concepts including:

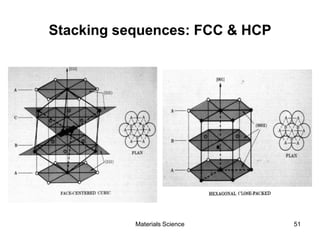

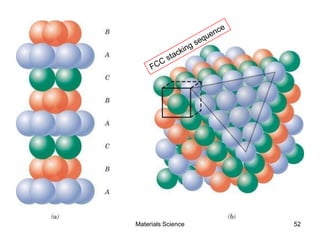

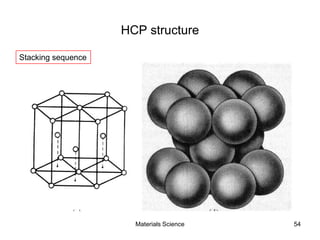

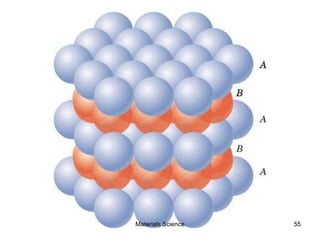

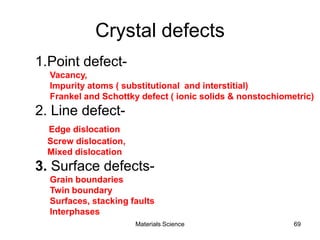

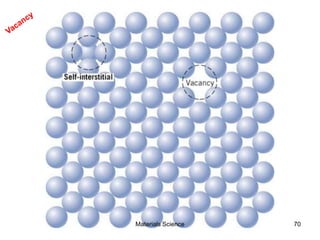

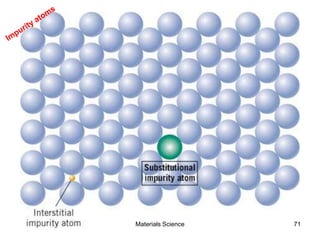

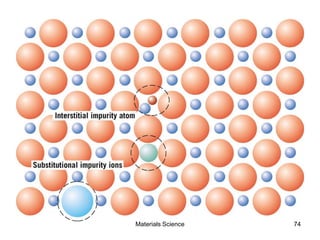

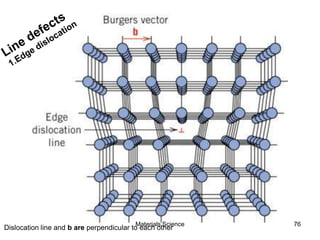

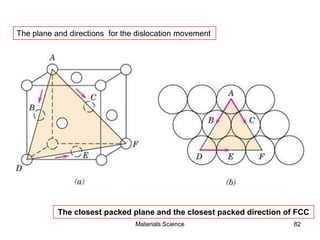

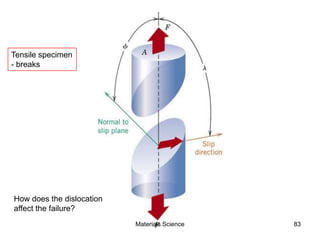

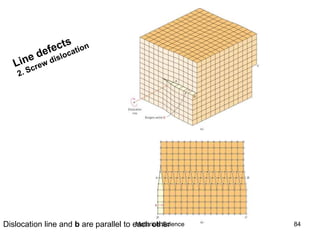

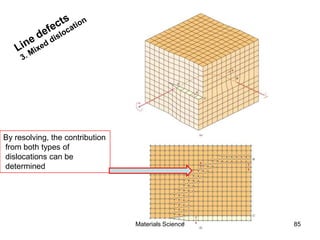

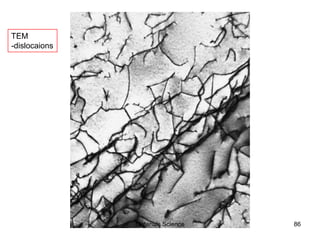

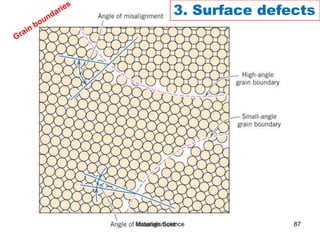

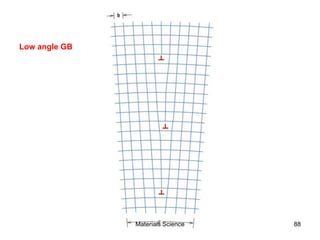

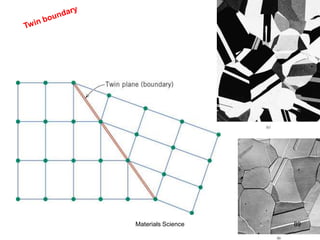

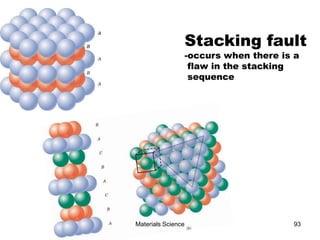

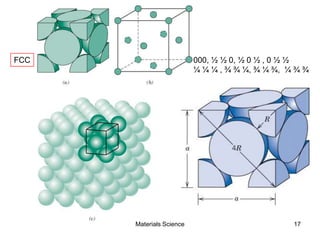

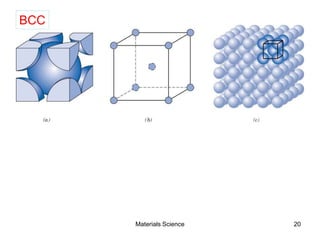

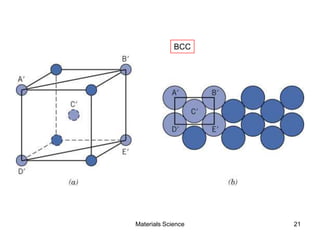

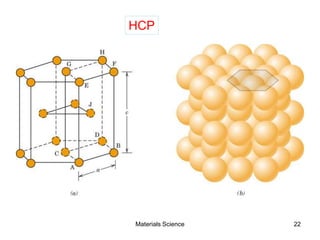

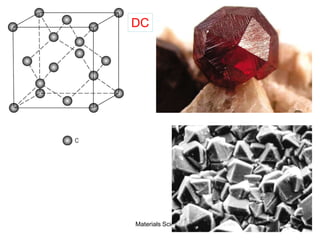

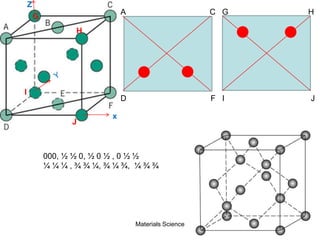

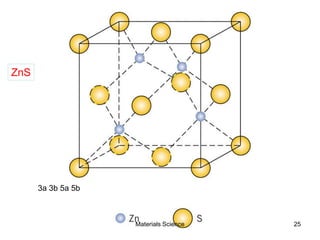

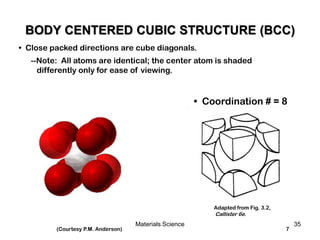

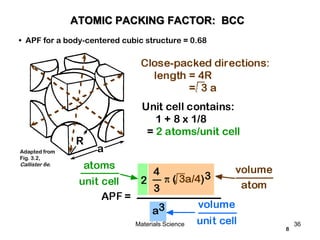

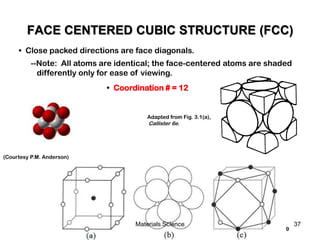

- Crystal structures such as FCC, BCC, and HCP. Defects like point defects, line defects, and dislocations are also introduced.

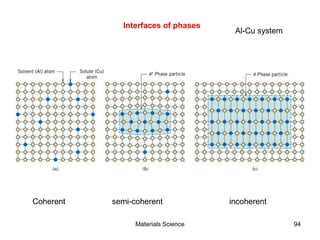

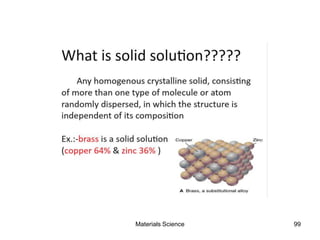

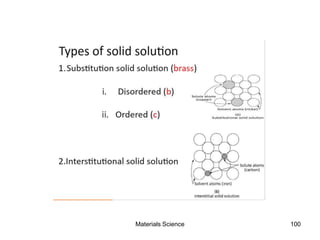

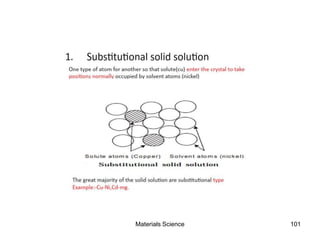

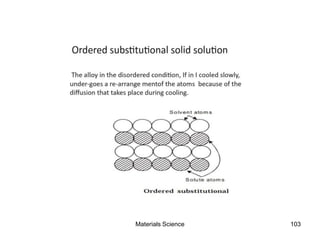

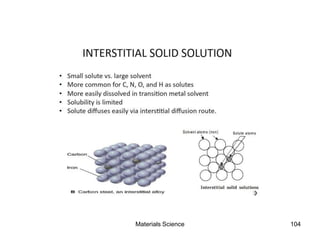

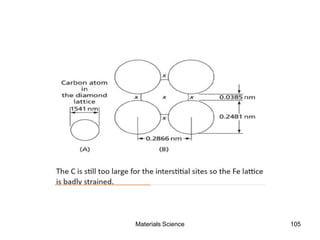

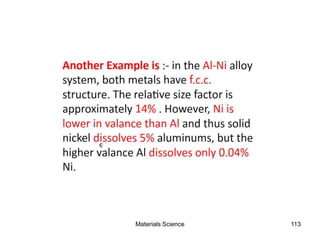

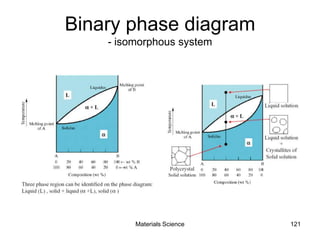

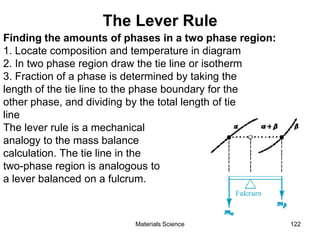

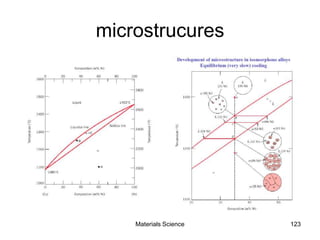

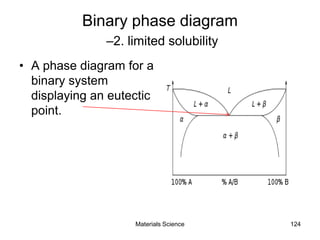

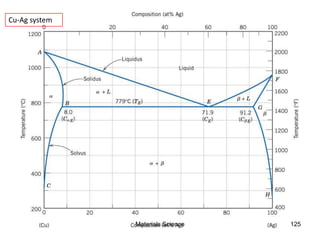

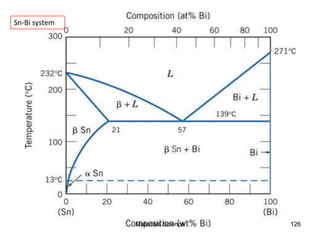

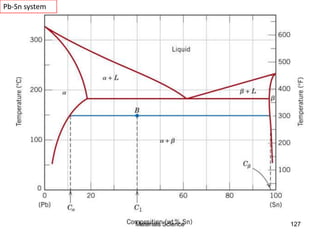

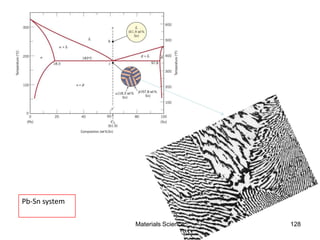

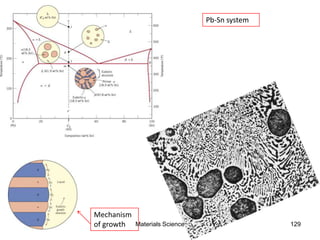

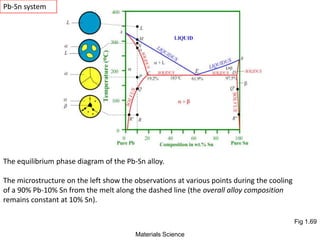

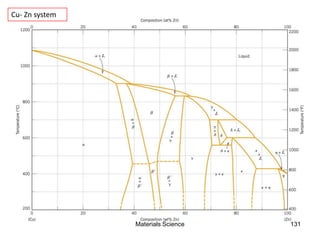

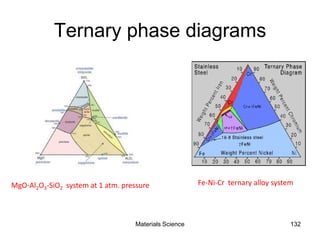

- Principles of alloy formation including solid solutions and binary phase diagrams. Common systems like Cu-Ni and Fe-C are discussed.

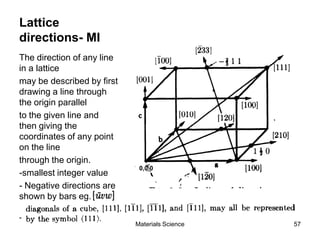

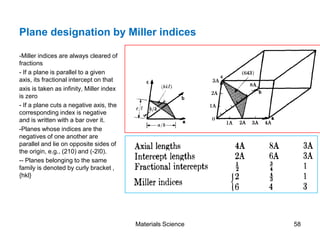

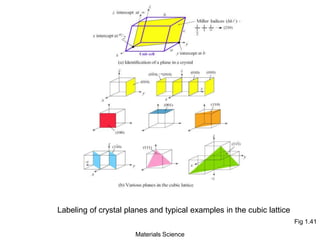

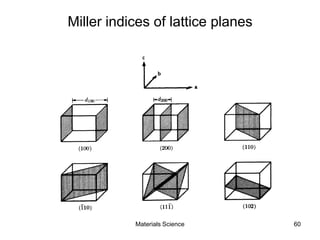

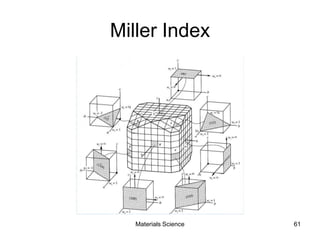

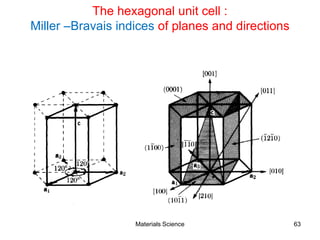

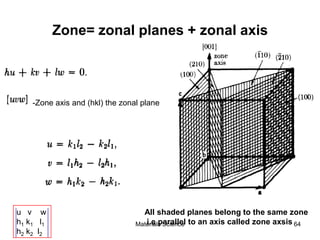

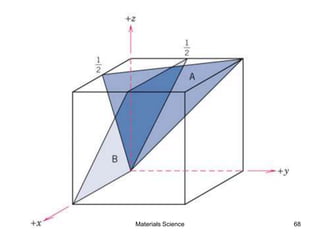

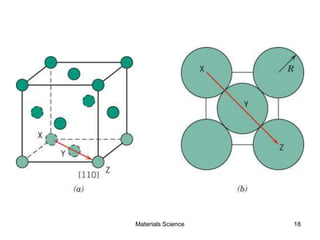

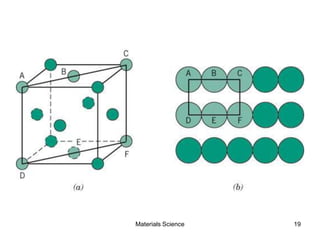

- Crystallography topics such as Miller indices, lattice planes, zone axes, and crystal directions.

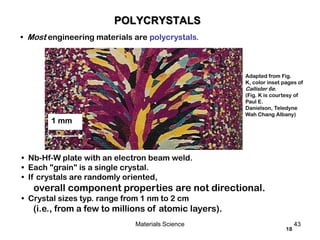

- Differences between single crystals and polycrystals and how they impact material properties.

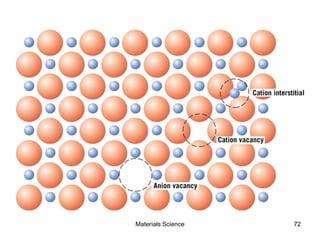

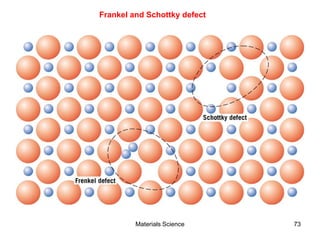

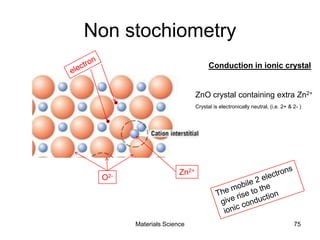

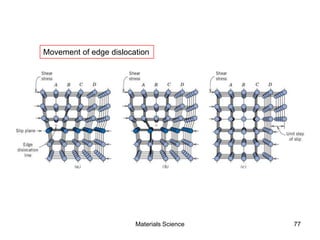

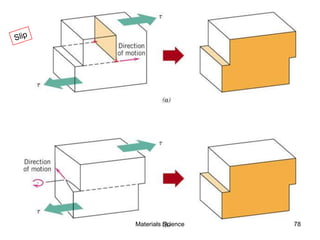

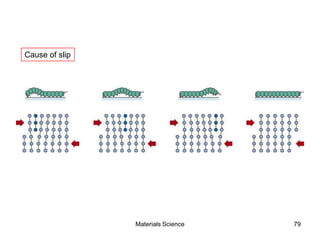

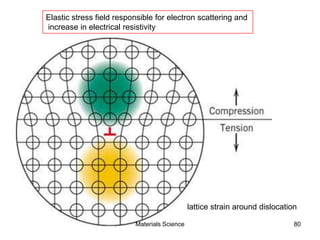

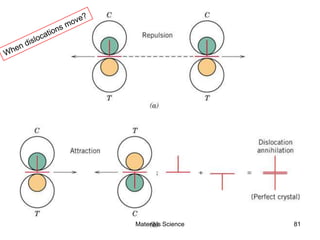

- Additional concepts covered include defects in ionic crystals, non-stoichiometry, and dislocation movement.

![19

• Single Crystals

-Properties vary with

direction: anisotropic.

-Example: the modulus

of elasticity (E) in BCC iron:

• Polycrystals

-Properties may/may not

vary with direction.

-If grains are randomly

oriented: isotropic.

(Epoly iron = 210 GPa)

-If grains are textured,

anisotropic.

200 m

Data from Table

3.3, Callister 6e.

(Source of data is

R.W.

Hertzberg, Deformatio

n and Fracture

Mechanics of

Engineering

Materials, 3rd

ed., John Wiley and

Sons, 1989.)

Adapted from Fig.

4.12(b), Callister 6e.

(Fig. 4.12(b) is

courtesy of L.C. Smith

and C. Brady, the

National Bureau of

Standards,

Washington, DC [now

the National Institute

of Standards and

Technology,

Gaithersburg, MD].)

SINGLE VS POLYCRYSTALS

44Materials Science](https://image.slidesharecdn.com/crystalography-140401234432-phpapp01/85/Crystalography-44-320.jpg)