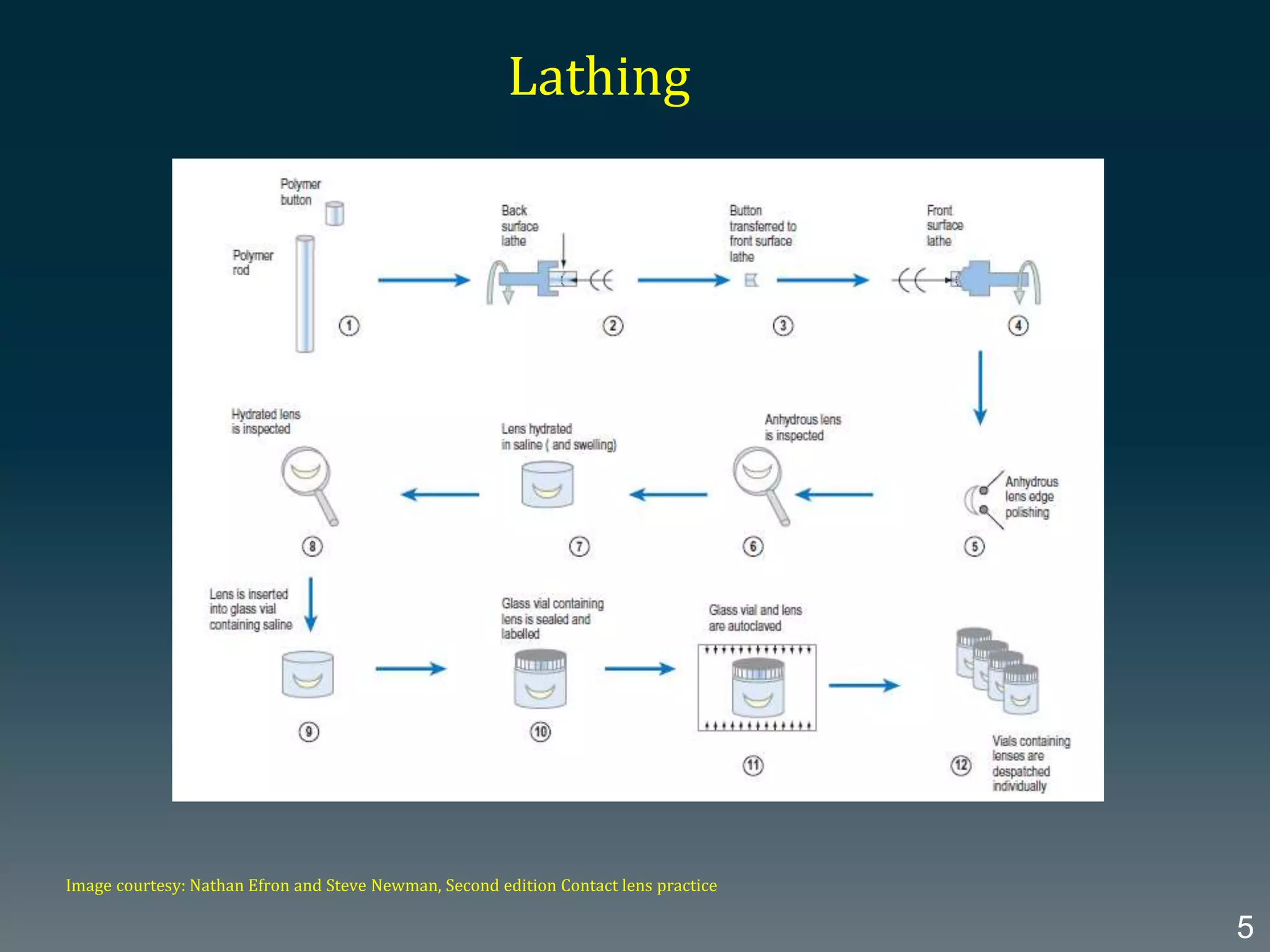

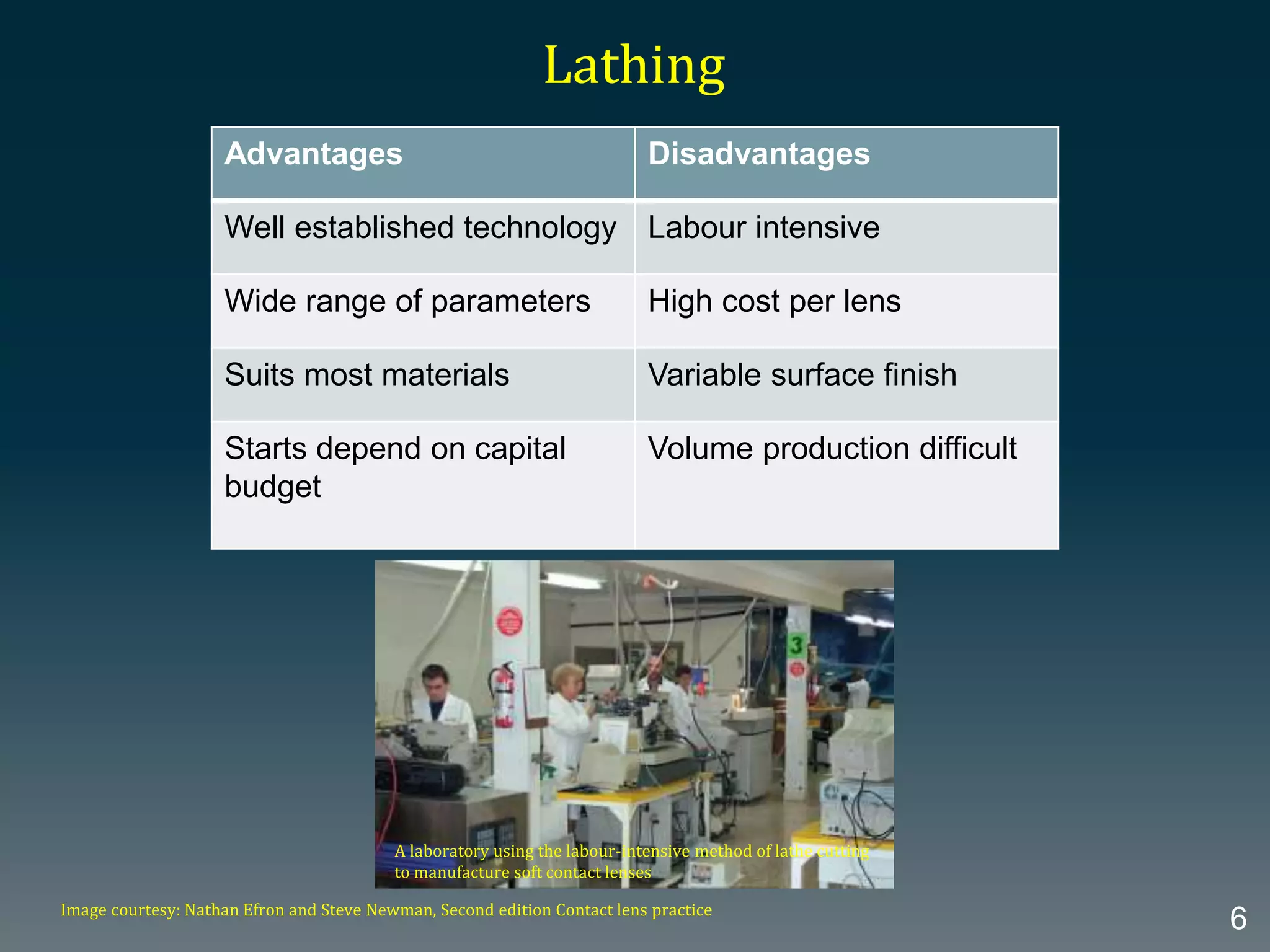

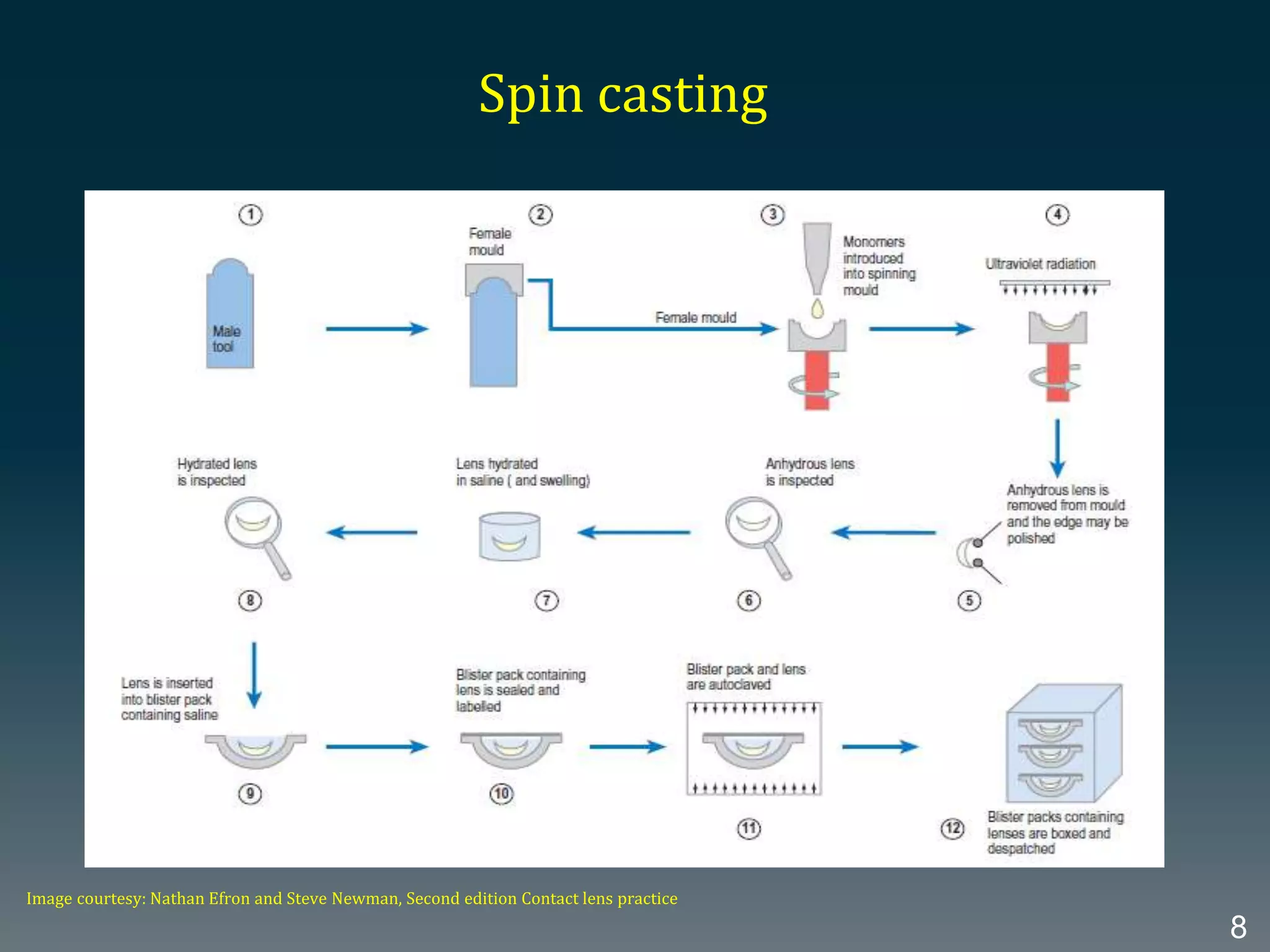

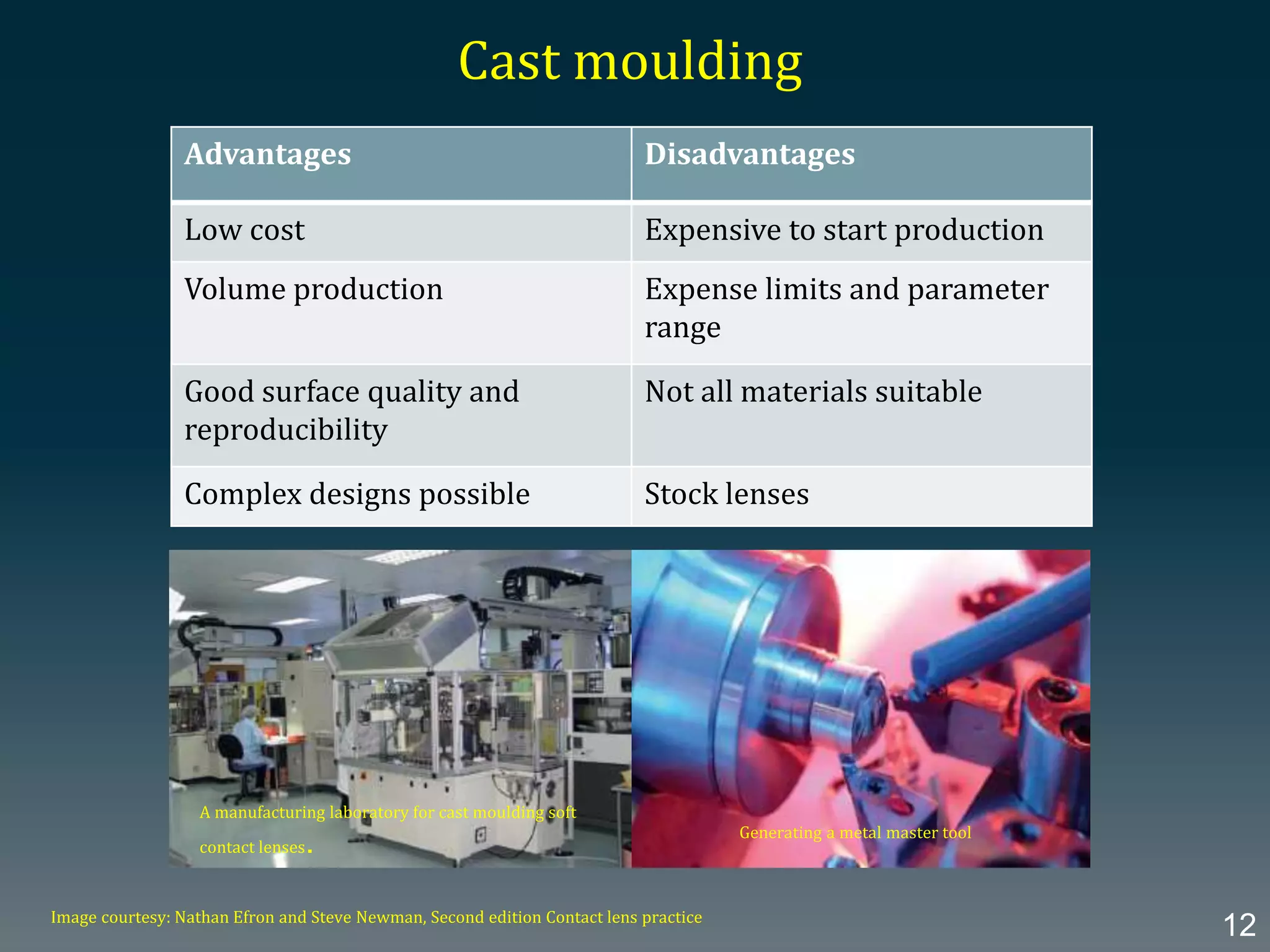

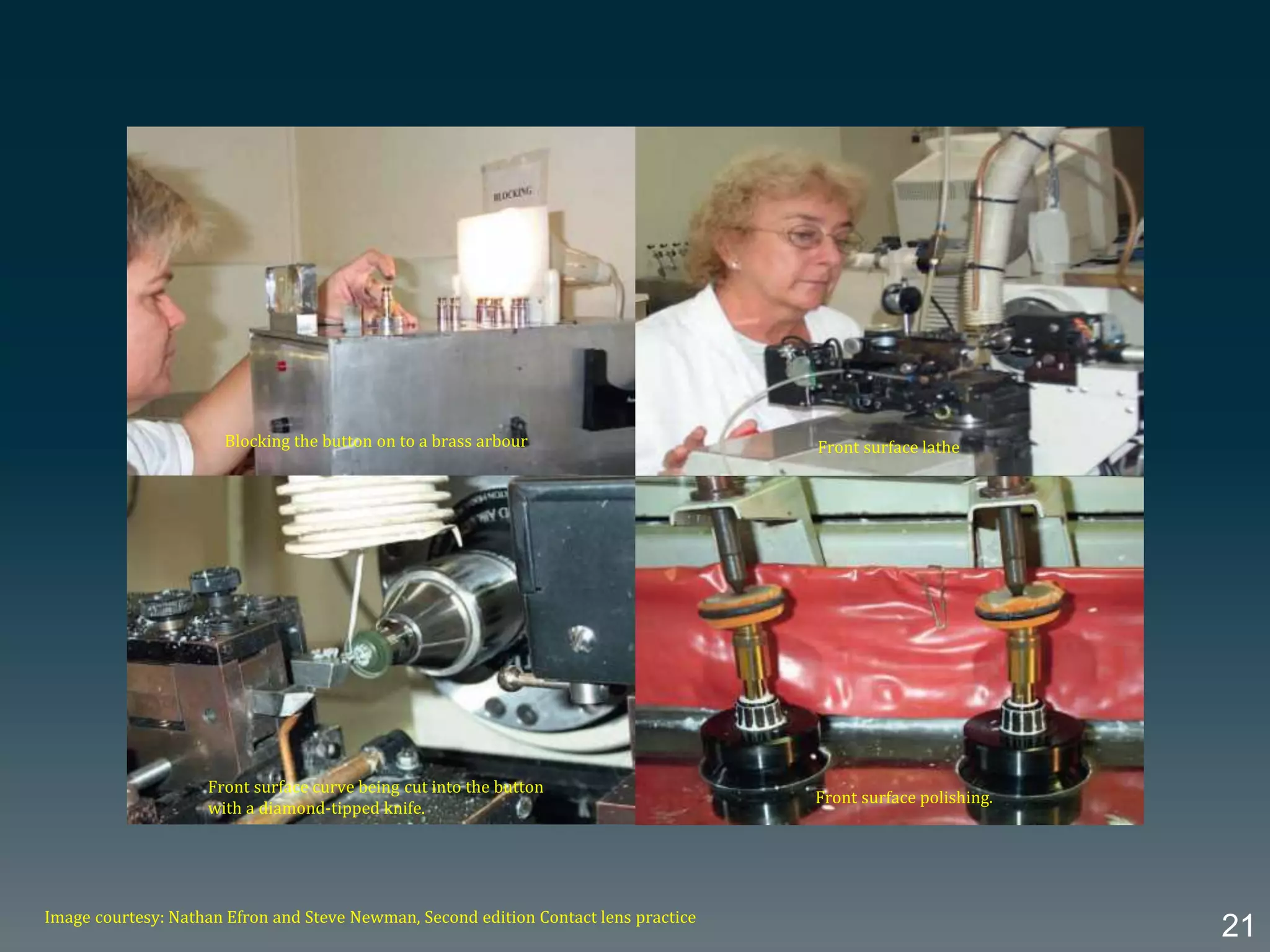

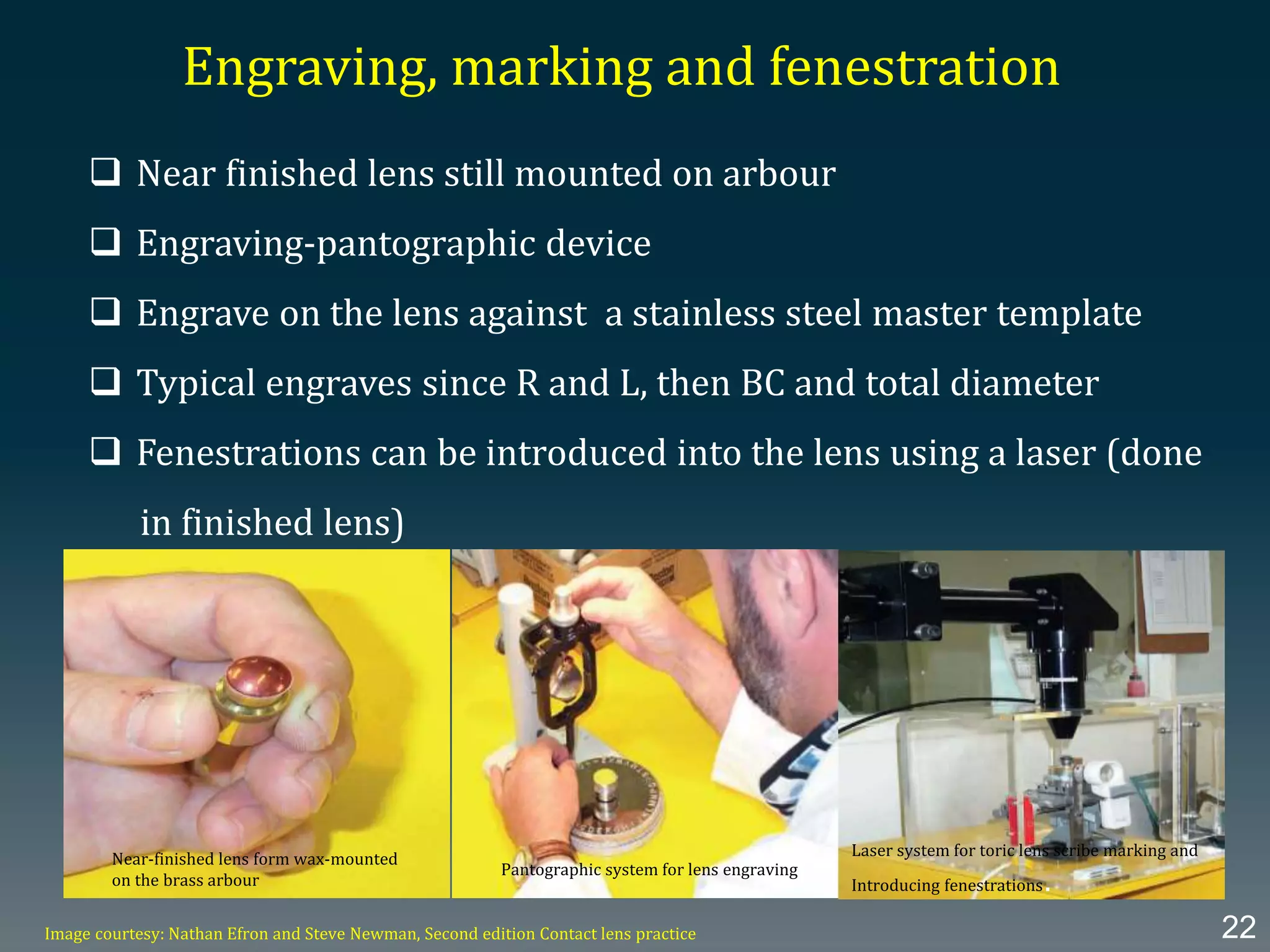

This document summarizes various contact lens manufacturing techniques. It discusses soft lens manufacturing methods like moulding, spin casting, and lathing. It describes how these techniques work, their advantages and disadvantages. Rigid gas permeable contact lenses are lathed from cylindrical buttons using back surface and front surface lathes. Additional processes for both soft and rigid lenses include edge polishing, marking, fenestration and final inspection. The document is intended as an overview of contact lens manufacturing processes.