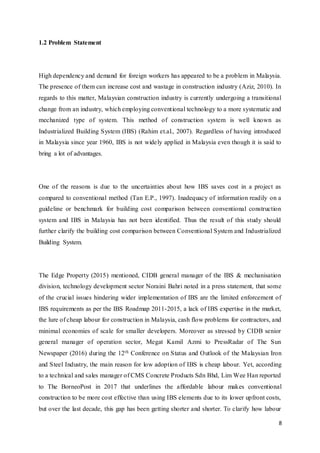

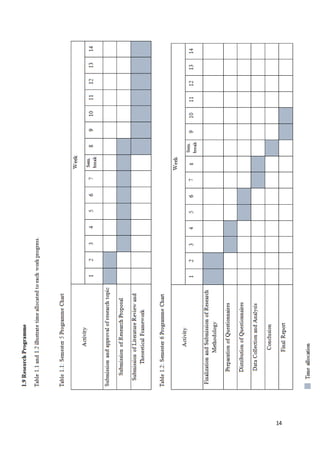

This document is a research proposal submitted by Than Lek Mei to compare the cost of buildings constructed using the conventional construction method versus the Industrialized Building System (IBS) in Malaysia. The proposal includes an introduction that provides background on IBS implementation in Malaysia, a problem statement on the low adoption of IBS despite its benefits, and a literature review on previous similar studies that have shown conflicting results. The research aims and objectives are defined as determining the most common IBS systems used in Malaysia, identifying factors affecting the costs of both methods, and comparing costs between methods for residential buildings. The proposed research design involves document analysis, questionnaires, interviews, and case studies.