IRJET- Preventive Maintenance and Root Cause Analysis of Sealed Quench Furnace in Axle Heat Treatment Line

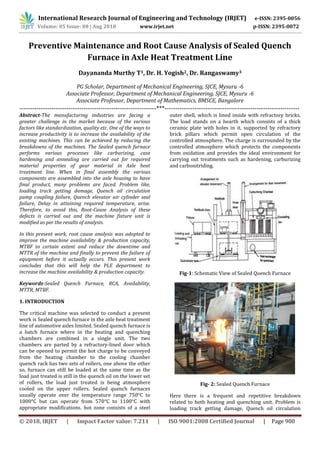

- 1. International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056 Volume: 05 Issue: 08 | Aug 2018 www.irjet.net p-ISSN: 2395-0072 © 2018, IRJET | Impact Factor value: 7.211 | ISO 9001:2008 Certified Journal | Page 900 Preventive Maintenance and Root Cause Analysis of Sealed Quench Furnace in Axle Heat Treatment Line Dayananda Murthy T1, Dr. H. Yogish2, Dr. Rangaswamy3 PG Scholar, Department of Mechanical Engineering, SJCE, Mysuru -6 Associate Professor, Department of Mechanical Engineering, SJCE, Mysuru -6 Associate Professor, Department of Mathematics, BMSCE, Bangalore ----------------------------------------------------------------***--------------------------------------------------------------- Abstract-The manufacturing industries are facing a greater challenge in the market because of the various factors like standardization, quality etc. One of the ways to increase productivity is to increase the availability of the existing machines. This can be achieved by reducing the breakdowns of the machines. The Sealed quench furnace performs various processes like carburizing, case hardening and annealing are carried out for required material properties of gear material in Axle heat treatment line. When in final assembly the various components are assembled into the axle housing to have final product, many problems are faced. Problem like, loading track getting damage, Quench oil circulation pump coupling failure, Quench elevator air cylinder seal failure, Delay in attaining required temperature, arise. Therefore, to avoid this, Root-Cause Analysis of these defects is carried out and the machine fixture unit is modified as per the results of analysis. In this present work, root cause analysis was adopted to improve the machine availability & production capacity, MTBF to certain extent and reduce the downtime and MTTR of the machine and finally to prevent the failure of equipment before it actually occurs. This present work concludes that this will help the PLE department to increase the machine availability & production capacity. Keywords-Sealed Quench Furnace, RCA, Availability, MTTR, MTBF. 1. INTRODUCTION The critical machine was selected to conduct a present work is Sealed quench furnace in the axle heat treatment line of automotive axles limited. Sealed quench furnace is a batch furnace where in the heating and quenching chambers are combined in a single unit. The two chambers are parted by a refractory-lined door which can be opened to permit the hot charge to be conveyed from the heating chamber to the cooling chamber quench rack has two sets of rollers, one above the other so, furnace can still be loaded at the same time as the load just treated is still in the quench oil on the lower set of rollers, the load just treated is being atmosphere cooled on the upper rollers. Sealed quench furnaces usually operate over the temperature range 750°C to 1000°C but can operate from 570°C to 1100°C with appropriate modifications. hot zone consists of a steel outer shell, which is lined inside with refractory bricks. The load stands on a hearth which consists of a thick ceramic plate with holes in it, supported by refractory brick pillars which permit open circulation of the controlled atmosphere. The charge is surrounded by the controlled atmosphere which protects the components from oxidation and provides the ideal environment for carrying out treatments such as hardening, carburizing and carbonitriding. Fig-1: Schematic View of Sealed Quench Furnace Fig- 2: Sealed Quench Furnace Here there is a frequent and repetitive breakdown related to both heating and quenching unit. Problem is loading track getting damage, Quench oil circulation

- 2. International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056 Volume: 05 Issue: 08 | Aug 2018 www.irjet.net p-ISSN: 2395-0072 © 2018, IRJET | Impact Factor value: 7.211 | ISO 9001:2008 Certified Journal | Page 901 pump coupling failure, Quench elevator air cylinder seal failure, Delay in attaining required temperature. Due to this problem the machine availability is decreased and this is a frequent breakdown. There was a decrease in production capacity and MTBF. Hence in this present work an attempt has been made to overcome the above problems by incorporating new preventive maintenance schedules with safety interlock. To obtain the new preventive maintenance schedule. repeated breakdowns were identified, inspected and analysed using Root cause analysis technique like why- why analysis and fishbone diagram. These techniques helped in increasing availability and MTBF to certain extent and reduce the downtime and finally to prevent the failure of equipment before it actually occurs. 1.1 Methodology of Work 1. Study of production process 2. Setting the objectives for the study 3. Data collection for breakdown status 4. Analysis of the data collected 5. Selection of appropriate tools and techniques for the study 6. Identify the breakdowns which are most critical 7. Finding the root causes of the breakdowns a. Fishbone diagram b. Why-why analysis 8. Implement of counter measures 9. Check the results 10. Improvement of a new preventive maintenance schedule. 2. ROOT CAUSE ANALYSIS RCA is a technique of evaluating a particular problem/breakdown considering the important factors which are responsible for that problem/breakdown to arise. Root Cause is that, if corrected, would prevent recurrence of the similar breakdown. The root cause does not apply to this occurrence only, but has general suggestions to a broad group of possible occurrences, and it is the best fundamental aspect of the cause that can logically be identified and modified. There may be a series of causes that can be identified, one leading to another. This series should be followed until the essential, correctable cause has been identified. This method is considered to be the most reliable method of analysis in most of the industries. Many Root Cause Analysis Tools have developed from the literature as general standards for identifying root causes. Why-Why Analysis tool was used to determine the root cause in this present work. 2.1 Root Cause Analysis And Implementation 2.1.1 Break down description - Loading track getting damage Root cause - No proper rigid support for furnace track Physical phenomenon - High temperature inside furnace Table-1: Why-Why analysis of Loading Track Problem Loading track getting damage Why? Track getting bend due to high temperature inside the furnace Why? Temperature inside furnace is around 900˚C Why? No proper rigid support for furnace track Why? Original design was not proper Counter measures - Extra strength provided by introducing sillimanite Carbide bricks & SS 310 bracket and cementing it from all side for rigid track. Fig – 3: Before Counter Measure

- 3. International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056 Volume: 05 Issue: 08 | Aug 2018 www.irjet.net p-ISSN: 2395-0072 © 2018, IRJET | Impact Factor value: 7.211 | ISO 9001:2008 Certified Journal | Page 902 Fig – 4: After Counter Measure 2.1.2 Break down description - Delay in attaining required temperature Root cause - Original design was not proper Physical phenomenon - Heat loss near burner area Table -2: Why-Why analysis of Furnace Temperature Problem Delay in attaining required temperature Why? Required temperature was not maintained throughout a cycle Why? Heat loss near burner area Why? Manual firing was not systematic Why? Original design was not proper Counter measures - Burner design modified close firing provided with auto ignition Fig -5: Before Counter Measure Fig - 6: After Counter Measure 2.1.3 Break down description -Quench oil circulation pump coupling failure Root cause - Pump motor coupling Misalignment Physical phenomenon - coupling spider failure Table – 3: Why-Why analysis of pump Problem Quench oil circulation pump coupling failure Why? Quench oil pump coupling spider failure Why? Pump motor coupling Misalignment Why? Fail in safe guard coupling Why? Maintenance was not proper Counter Measure - Coupling modified by using in house flexible flat belt and flange. Fig – 7: Before Counter Measure

- 4. International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056 Volume: 05 Issue: 08 | Aug 2018 www.irjet.net p-ISSN: 2395-0072 © 2018, IRJET | Impact Factor value: 7.211 | ISO 9001:2008 Certified Journal | Page 903 Fig 8: After Counter Measure 2.1.4 Break down description - Quench elevator air cylinder seal failure Root cause - Cylinder is only 100 mm away from the furnace body Physical phenomenon – High temperature Table – 4: Why-Why analysis of cylinder seal Problem Quench elevator air cylinder seal failure Why? Piston seal leakage Why? Temperature is high Why? Cylinder is only 100 mm away from the furnace body Why? Original design was not proper Counter measures - The cylinder height increased from the furnace body to 1.4m. Fig – 9: Before Counter Measure Fig - 10: After Counter Measure 3. RESULTS Table-5: Comparison of results before and after implementation of counter measures of sealed quench furnace Fig - 11: Graph showing comparison of availability before and after implementation of counter measures Fig - 12: Graph showing comparison of MTBF before and after implementation of counter measures

- 5. International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056 Volume: 05 Issue: 08 | Aug 2018 www.irjet.net p-ISSN: 2395-0072 © 2018, IRJET | Impact Factor value: 7.211 | ISO 9001:2008 Certified Journal | Page 904 Fig -13: Graph showing comparison of MTTR before and after implementation of counter measures The usage of root cause analysis helped to identify the correct causes of failures by which the suitable countermeasures are developed and implemented. The process measurable such as Availability, MTBF, and MTTR are calculated before and after the implementation of counter measures. Continuous monitoring of processes is done after the implementation of counter measures. 4. CONCLUSION The following conclusions are drawn: The Availability of sealed quench furnace is increased from 96.07 to 99.13%. The MTBF of sealed quench furnace is increased from 78.66 to 230 hours. The MTTR of sealed quench furnace is decreased from 3.21 to 2 hours. The Effectiveness of preventive maintenance of sealed quench furnace is improved. The Breakdowns such as loading track damage, Quench oil circulation pump coupling failure, Quench elevator air cylinder seal failure and delay in attaining required temperature in sealed quench furnace is eliminated. REFERENCES [1] "Maintenance planning and control" - Anthony Kelly. East west press Pvt. Ltd., 1984 [2] "Root cause analysis in aircraft final assembly" - Brown J I. Master abstract international 1994 [3] “Management of Industrial maintenance” Anthony kelly and M.I.Hrris Butterworth and co.Ltd.,1978 [4] Naveen K.J, Dr.H.Yogish, “Preventive Maintenance and Root Cause Analysis of Soham Pre- Treatment Washing Machine in Axle Assembly Line” International Journal of Recent Trends in Engineering & Research, Volume 02, Issue 07, July 2016.