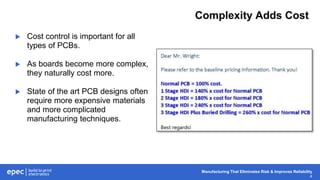

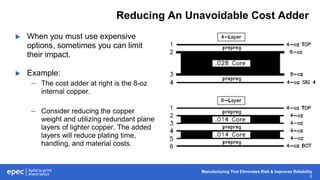

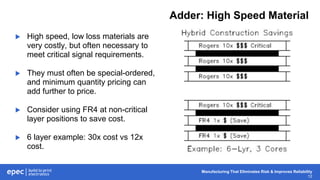

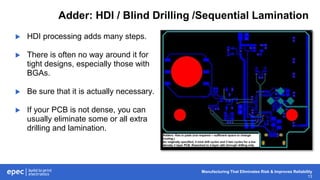

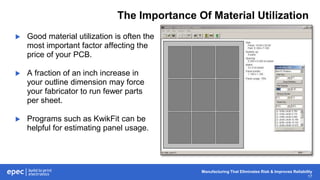

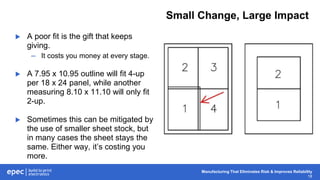

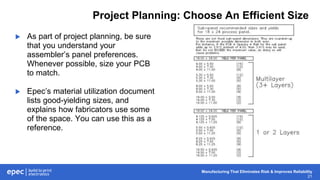

This document discusses cost-effective planning and design techniques for high-tech printed circuit boards (PCBs). It emphasizes identifying critical features, avoiding unnecessary complexity, and efficient material utilization to minimize production costs while maintaining performance requirements. The content includes practical guidelines and considerations for designers, from beginners to professionals, to control expenses and improve reliability in PCB manufacturing.