This document provides an overview of a training session on Measurement System Analysis (MSA). The session will be led by two trainers and will cover topics such as:

- Defining a measurement system and MSA

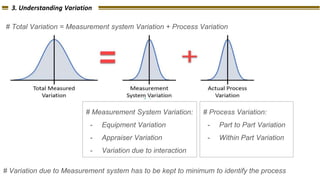

- Understanding variation from measurement systems versus process variation

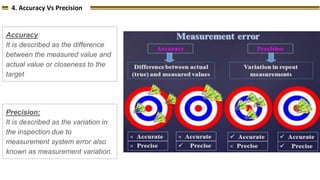

- Accuracy versus precision

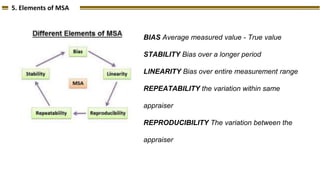

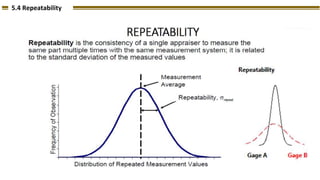

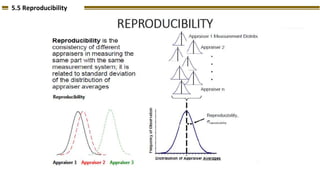

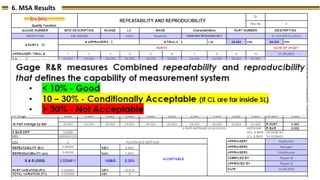

- Key elements of MSA like bias, linearity, stability, repeatability, and reproducibility

- Conditions for performing an effective MSA study

- Benefits of MSA like evaluating measurement system reliability and identifying sources of variation

The training contents include explanations of these MSA concepts along with examples to illustrate differences between accuracy and precision, potential sources of variation, and how to analyze MSA results.