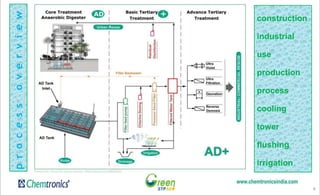

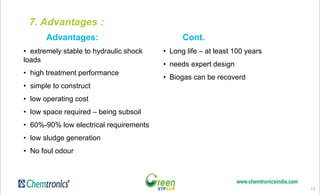

This document provides an overview of a High Rate Anaerobic Digester (HRAD) system with polishing for wastewater treatment. It describes the HRAD process which uses alternating standing and hanging baffles to facilitate contact between wastewater and residual sludge, allowing for high treatment rates. The system can optimize anaerobic digestion by treating all types of wastewater for reuse or disposal. Additional tertiary treatment like disinfection and filtration provides polished effluent suitable for various reuse applications. The HRAD achieves high removal of contaminants like COD, BOD, TSS and pathogens. It requires relatively low maintenance and has advantages of being stable, efficient, and producing low sludge and biogas

![22

Model no. Capacity AD Tank Area Plant Room Power

AD+/STP-20 20CMD 50 m2 x 3.0 m (D) 6.0 m2 x 3.0 m (H) 1.0 kW

AD+/STP-35 35 CMD 90 m2 x 3.0 m (D) 7.0 m2 x 3.0 m (H) 1.0 kW

AD+/STP-50 50 CMD 150 m2 x 3.0 m (D) 8.0 m2 x 3.0 m (H) 1.0 kW

AD+/STP-75 75 CMD 180 m2 x 3.0 m (D) 10.0 m2 x 3.0 m (H) 1.0 kW

AD+/STP-100 100 CMD 230 m2 x 3.0 m (D) 15.0 m2 x 3.0 m (H) 2.0 kW

AD+/STP-140 140 CMD 310 m2 x 3.0 m (D) 18.0 m2 x 3.0 m (H) 2.0 kW

AD+/STP-200 200 CMD 450 m2 x 3.0 m (D) 20.0 m2 x 3.0 m (H) 2.0 kW

AD+/STP-250 250 CMD 550 m2 x 3.0 m (D) 22.0 m2 x 3.0 m (H) 2.0 kW

AD+/STP-300 300 CMD 660 m2 x 3.0 m (D) 25.0 m2 x 3.0 m (H) 2.5 kW

AD+/STP-375 375 CMD 830 m2 x 3.0 m (D) 27.0 m2 x 3.0 m (H) 2.5 kW

8. Available Models [with tertiary treatment]](https://image.slidesharecdn.com/chemtronics-greenstpad-160317122641/85/Chemtronics-Green-STP-AD-22-320.jpg)